Method for preparing high-purity titanium by electrolyzing titanium scraps in molten salt

A molten salt, high-purity technology, applied in the field of electrochemical metallurgy, can solve the problems of difficult to reflect the actual value of metal titanium, cheap products, and high requirements for the composition of waste titanium elements, so as to achieve mature electrolysis process, improve recovery value, and efficiently recover The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

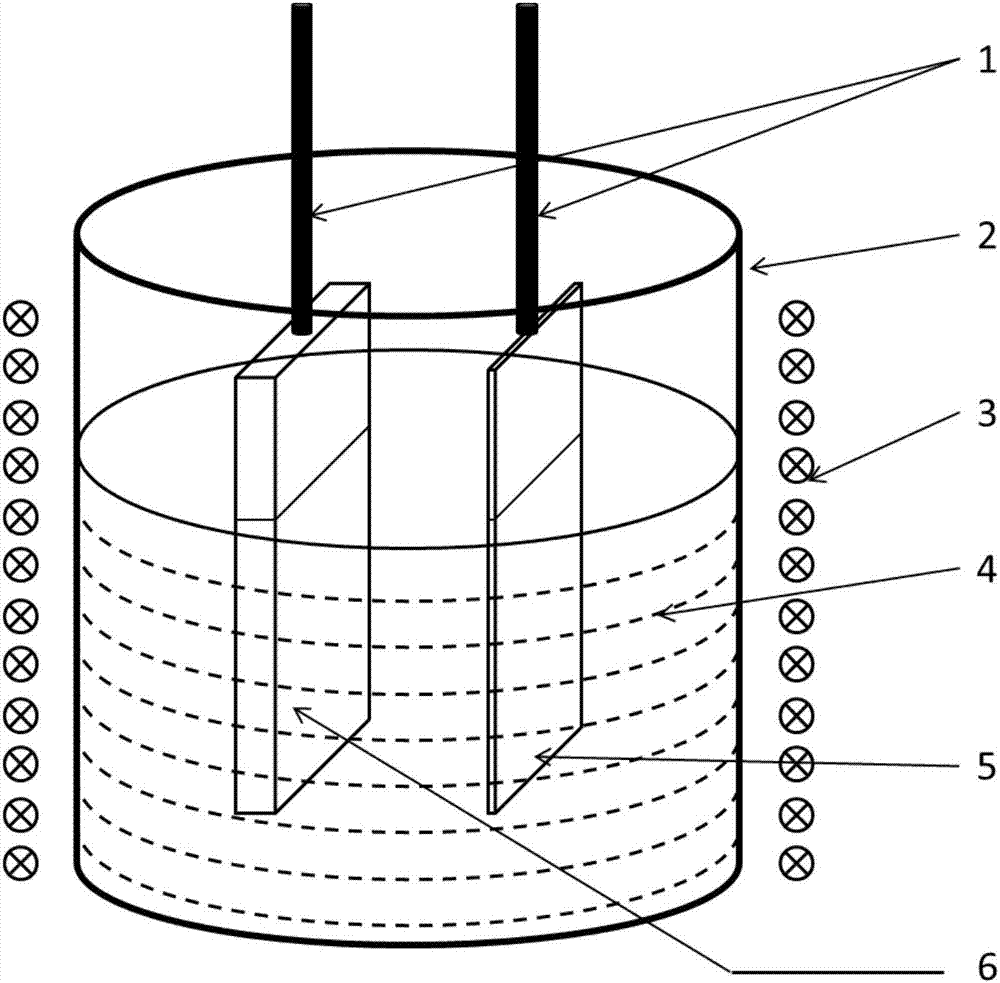

Embodiment 1

[0026] Use waste titanium such as car chips and shavings as the titanium source, and press it in the mold with a pressure of 10Mpa to obtain a 20mm thick, 100mm wide, and 500mm long block as the anode; take a 10mm thick, 100mm wide, and 500mm long nickel plate as the cathode ; The eutectic salt of anhydrous lithium chloride and potassium chloride is used as the electrolyte, and a low-priced titanium ion source is added to the molten salt through the reaction of metal titanium and titanium tetrachloride. Under the protection of argon, the electrolysis is carried out by means of constant current electrolysis, and the current density is controlled at 1A / cm 2 about. After 10 hours of electrolysis, the electrolysis was stopped, and the electrode was taken out from the molten salt. After the furnace temperature drops to 100°C, remove the cathode, wash with water to remove salt inclusions, then wash with 1mol / L dilute hydrochloric acid, and finally rinse with water and dry at 60°C t...

Embodiment 2

[0028] The titanium alloy parts scrapped by automobiles are used as the source of titanium ions. After being cut and broken, they are placed in a copper frame as the anode; the cathode is made of stainless steel plate; the electrolyte is a mixture of molten sodium chloride and potassium chloride containing low-priced titanium ions. crystal salt. Under the protection of an inert atmosphere, the furnace body was heated to 800°C, and after 1 hour of heat preservation, the cathode and anode were inserted into the molten salt and electrolyzed at a constant potential with a parameter of 0.2V / cm. After 10 hours of electrolysis, the electrode was taken out, and the temperature was lowered to 60°C. Then the cathode is taken out, washed with water, pickled, washed with water and dried, and finally the obtained high-purity titanium crystal is melted in an electron beam melting furnace to obtain a 4N grade high-purity titanium ingot.

Embodiment 3

[0030] Use waste titanium metal parts as titanium ion source, connect it to stainless steel electrode rod as anode; use nickel plate as cathode; electrolyte is eutectic salt of molten sodium chloride, potassium chloride and lithium chloride containing low-valent titanium ions. Under the protection of an inert atmosphere, the furnace body was heated to 700 ° C, and after 1.5 hours of heat preservation, the cathode and anode were inserted into the molten salt and electrolyzed at a constant potential with a parameter of 0.3V / cm. After 20 hours of electrolysis, the electrode was taken out, and the temperature was lowered to 20°C. Then the cathode is taken out, washed with water, pickled, washed with water and dried, and finally the obtained high-purity titanium crystal is melted in an electron beam melting furnace to obtain a 4N grade high-purity titanium ingot.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com