Colorful solar cell and preparation method thereof

A solar cell, colorful technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of inability to reduce costs, high prices, and difficulty in reducing product manufacturing costs, and achieve low manufacturing costs, reasonable structure, and simple preparation methods. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The concrete steps of preparation are:

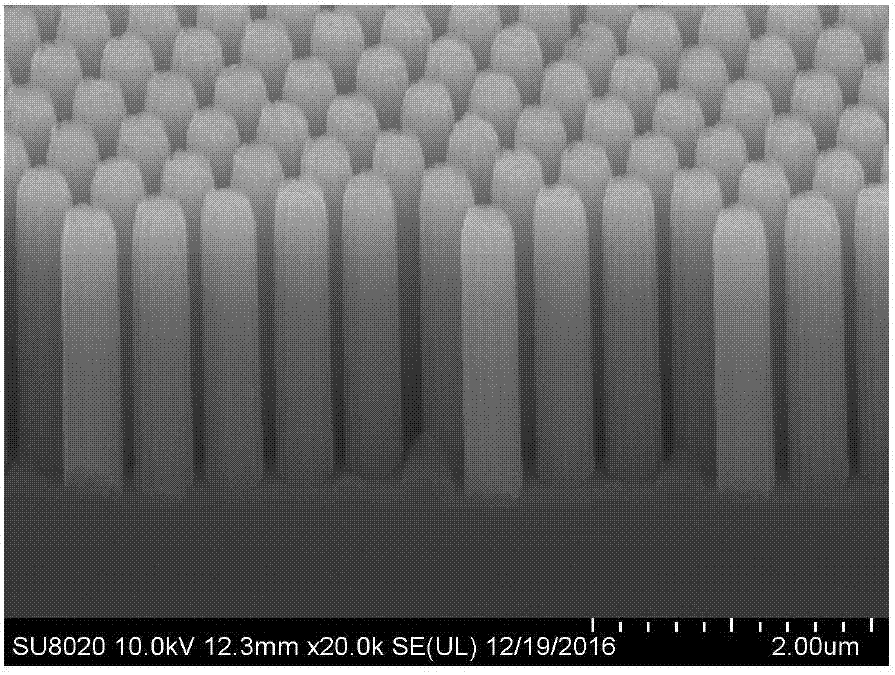

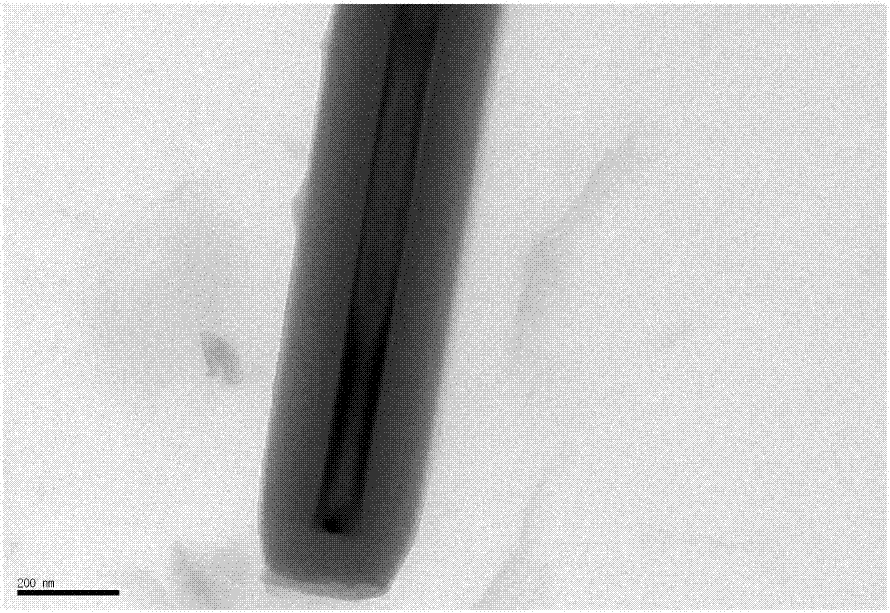

[0036] Step 1, using the nanosphere template method to make an ordered mask on the surface of the silicon substrate; wherein, the silicon substrate is a single crystal silicon substrate, and the process of using the nanosphere template method to make an ordered mask is to make a single layer dense After the row of polystyrene colloidal nanospheres with a diameter of 500nm is transferred to the surface of the silicon substrate, the diameter of the nanospheres is reduced to 50nm. A gold film with a thickness of 20 nm was evaporated on the surface to obtain a silicon substrate covered with an ordered gold mask. Then use a wet process to etch an ordered nanowire array on the silicon substrate covered with an ordered gold mask; wherein, the process of using a wet process to etch an ordered nanowire array is to cover the surface with The silicon substrate of the ordered gold mask was placed in 15 vol% hydrofluoric acid aqueous solutio...

Embodiment 2

[0040] The concrete steps of preparation are:

[0041] Step 1, using the nanosphere template method to make an ordered mask on the surface of the silicon substrate; wherein, the silicon substrate is a single crystal silicon substrate, and the process of using the nanosphere template method to make an ordered mask is to make a single layer dense After the row of polystyrene colloidal nanospheres with a diameter of 750nm is transferred to the surface of the silicon substrate, the diameter of the nanospheres is reduced to 68nm, and then, using the colloidal sphere template as a mask, the electron beam evaporation equipment is applied to the surface of the silicon substrate. A gold film with a thickness of 23 nm was evaporated on the surface to obtain a silicon substrate covered with an ordered gold mask. Then use a wet process to etch an ordered nanowire array on the silicon substrate covered with an ordered gold mask; wherein, the process of using a wet process to etch an ordere...

Embodiment 3

[0045] The concrete steps of preparation are:

[0046] Step 1, using the nanosphere template method to make an ordered mask on the surface of the silicon substrate; wherein, the silicon substrate is a single crystal silicon substrate, and the process of using the nanosphere template method to make an ordered mask is to make a single layer dense After the row of polystyrene colloidal nanospheres with a diameter of 1000nm is transferred to the surface of the silicon substrate, the diameter of the nanospheres is reduced to 85nm, and then, using the colloidal sphere template as a mask, the electron beam evaporation equipment is applied to the surface of the silicon substrate. A gold film with a thickness of 25 nm was evaporated on the surface to obtain a silicon substrate covered with an ordered gold mask. Then use a wet process to etch an ordered nanowire array on the silicon substrate covered with an ordered gold mask; wherein, the process of using a wet process to etch an order...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wire diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com