A kind of indenofluorene compound-graphene OLED photoelectric display material and preparation method

A photoelectric display and graphene technology, applied in the direction of circuits, electrical components, electrical solid devices, etc., can solve problems such as poor film formation of suspension coating, device failure, film splitting, etc., to achieve clean production process, reduce internal resistance, reduce The effect of production difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

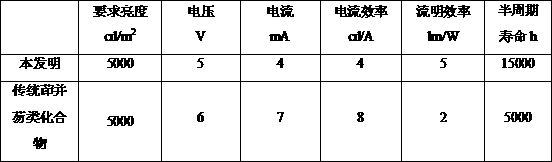

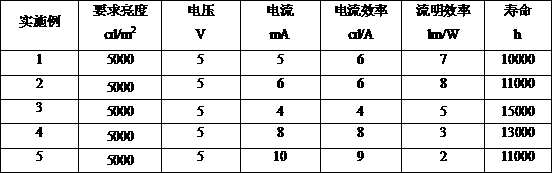

Examples

Embodiment 1

[0030] (1) Crushing waste polystyrene and its derivatives containing benzene rings into a volume of 2cm 3 Mix the obtained waste particles with the alkaline solution sodium hydroxide solution according to the solid-to-liquid mass ratio of 1:5, heat the temperature of the solution to 70°C, keep the temperature for 1 hour, and remove the surface after washing with deionized water The oil stain obtained is dried at 60°C to obtain pretreated particles;

[0031] (2) Add the obtained pretreated particles into catalyst iron powder, the mass ratio of iron powder to pretreated particles is 0.01:10, control the working pressure parameter of the high-pressure homogenizer to 20 MPa, and use the high-pressure homogenizer to fully mix the pretreated particles and iron powder to obtain a mixture;

[0032] (3) Put the obtained mixture into an autoclave, fill it with inert gas, increase the pressure to 20MPa at a rate of 0.1MPa / s, and heat the mixture from room temperature to 1000°C at a fixe...

Embodiment 2

[0036] (1) Break waste polystyrene and its derivatives containing benzene rings into waste particles with a volume of 5 cubic centimeters, mix the obtained waste particles with potassium hydroxide aqueous solution at a solid-to-liquid mass ratio of 1:6, and heat the solution The temperature is 80°C, and the heat preservation treatment time is 1.2 hours. After washing with deionized water to remove the oil on the surface, dry the obtained solid at 66°C to obtain pretreated particles;

[0037] (2) Add the obtained pretreated particles into catalyst nickel powder, the mass ratio of nickel powder to pretreated particles is 0.04:10, control the working pressure parameter of the high-pressure homogenizer to 30MP, and use the high-pressure homogenizer to fully mix the pretreated particles and the catalyst get the mixture;

[0038] (3) Put the obtained mixture into an autoclave, fill it with helium, increase the pressure to 30MPa at a rate of 0.3MPa / s, and heat the mixture from room t...

Embodiment 3

[0042] (1) Crush waste polystyrene and its derivatives containing benzene rings into waste particles with a volume of 8 cubic centimeters, mix the obtained waste particles with an alkaline solution at a solid-liquid mass ratio of 1:8, and heat the solution to a temperature of 80 ℃, heat preservation treatment time is 2 hours, after washing with deionized water to remove the oil on the surface, dry the obtained solid at 75 ℃ to obtain pretreated particles;

[0043] (2) Add the obtained pretreated particles to the catalyst nickel nitrate, the mass ratio of nickel nitrate to pretreated particles is 0.05:10, control the working pressure parameter of the high pressure homogenizer to 50MPa, and use the high pressure homogenizer to fully mix the pretreated particles and the catalyst get the mixture;

[0044] (3) Put the obtained mixture into an autoclave, fill it with nitrogen, increase the pressure to 35MPa at a rate of 0.7MPa / s, and heat the mixture from room temperature to 700°C a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com