A kind of catalyst for producing methyl acetate, its preparation method and application

A methyl acetate and catalyst technology, applied in the directions of carbon monoxide or formate reaction preparation, molecular sieve catalyst, chemical instruments and methods, can solve problems such as easy deactivation, reduce maintenance costs, reduce catalyst dosage, and achieve long catalyst life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Example 1 Preparation of Hydrogen EMT Zeolite Molecular Sieve

[0045] According to the method in the literature Synthesis of silica-rich faujasite using crown-ethers as templates: F. Delprato et, ZEOLITES, 1990, VOl 10:546, an EMT molecular sieve with a silicon-to-aluminum ratio of 4.2 was prepared.

[0046] Exchange the EMT molecular sieve with 0.5mol / L ammonium nitrate three times (2 hours / time), wash with deionized water, dry, and calcinate at 550°C for 4 hours to obtain the hydrogen type EMT zeolite molecular sieve, which is recorded as sample 1. # .

Embodiment 2 4

[0047] Example 2 Preparation of silicon tetrachloride vapor dealumination hydrogen type EMT zeolite molecular sieve

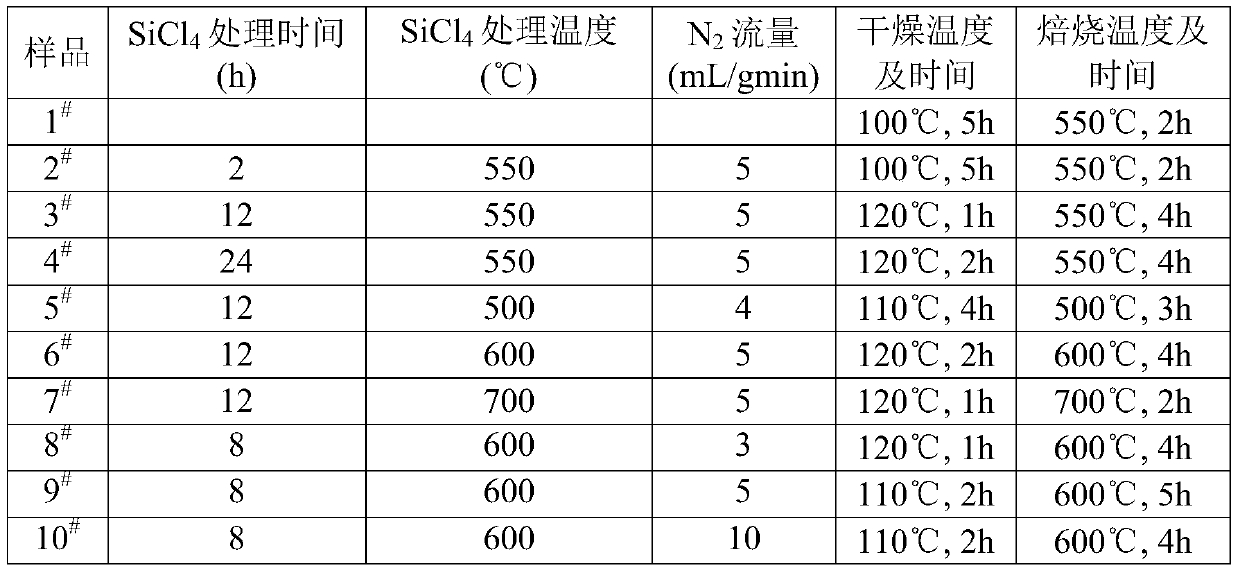

[0048] Weigh 1g of hydrogen type EMT zeolite molecular sieve, fix both ends in a quartz tube with quartz wool, and introduce 273K saturated silicon tetrachloride vapor carried by nitrogen. After the obtained solid sample is washed with deionized water, separated by filtration, dried and roasted, a catalyst for the carbonylation of dimethyl ether to produce methyl acetate is obtained. Table 1 shows the relationship between the temperature and time of silicon tetrachloride steam treatment, the temperature and time of solid sample drying and roasting, and the sample number.

[0049] Table 1

[0050]

Embodiment 3 4

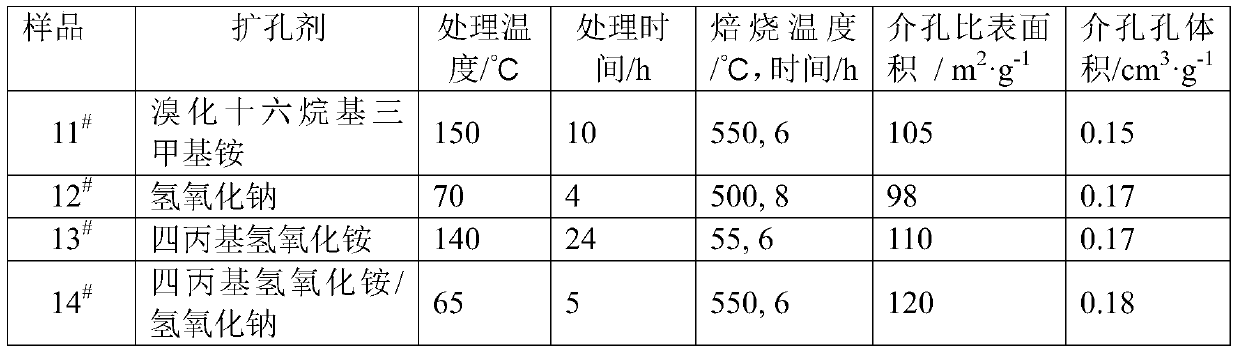

[0051] Example 3 Preparation of silicon tetrachloride vapor dealumination hydrogen type EMT zeolite molecular sieve (using pore expander)

[0052] 1.00g sample 6 # Add pore expander, then filter, wash, dry and roast to make 2 catalyst samples. Table 2 shows the relationship between the pore expander used, the processing temperature and time, the specific surface area and volume of the mesoporous sample and the sample number.

[0053] Table 2

[0054]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com