Series flexible thin film solar cell module and making method thereof

A technology for solar cells and flexible thin films, applied in the field of solar cells, can solve the problems affecting cell efficiency, cell dead zone, complicated processes, etc., and achieve the effects of easy process control, low manufacturing cost, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

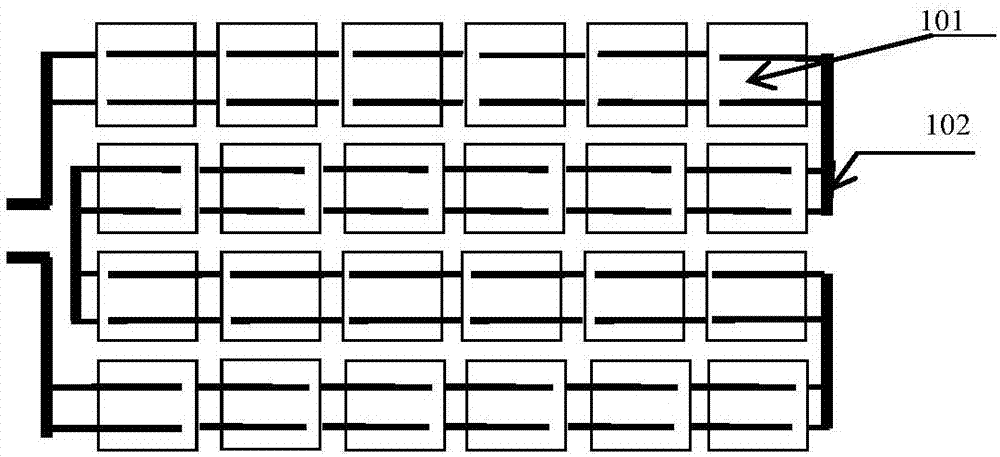

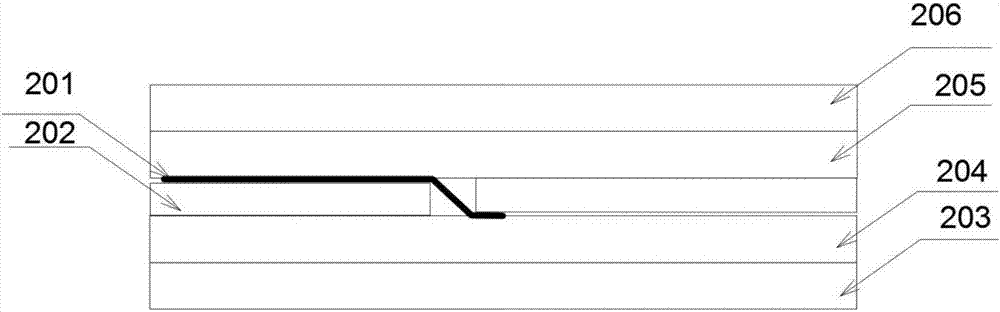

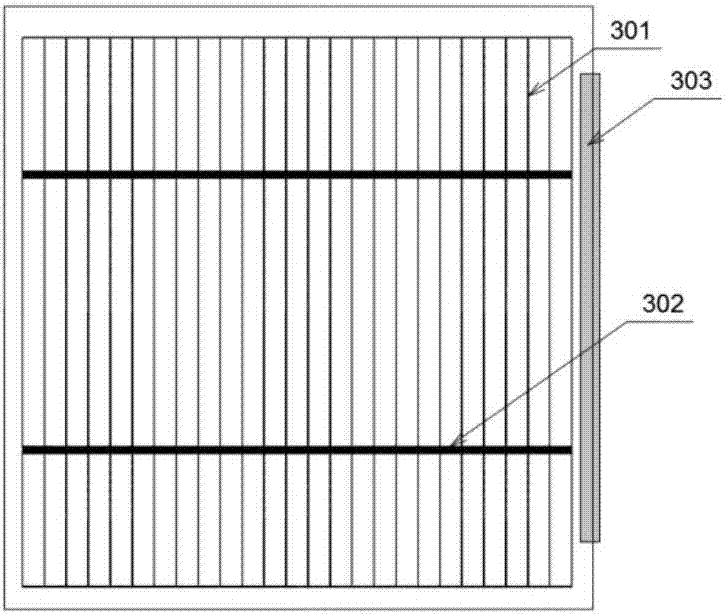

[0067] see figure 1 , figure 2 , image 3 and Figure 4 , a tandem flexible CIGS thin-film solar cell, including 24 flexible solar cell units 101, the flexible solar cell includes a flexible cell basic unit 101, a conductive adhesive tin-copper strip 201, a conductive welding bus strip 102, adjacent In the basic unit of the flexible solar cell, the current collection is realized through the grid lines (main grid line 301, thin grid line 302), and then the conductive adhesive tin copper strip 201 is bonded to the position of the main grid line, and the length of the lead is 15mm, and the next unit The substrates of the flexible solar cells 202 are connected to form a series structure, thereby forming a series of flexible solar thin film cells. The flexible solar thin film cells include a flexible metal substrate 401 and a power generation film layer 402 .

[0068] In this embodiment, the laminated packaging material of the flexible solar cell adopts ethylene-octene copolyme...

example 2

[0071] The same or similar technical content in this embodiment as in Embodiment 1 will not be described one by one in this embodiment.

[0072] In this embodiment, the current collection part of the basic unit of the flexible solar cell is still collected through the grid line. When converging with the current of the adjacent battery unit, the conductive welding bus strip 102 is used to realize the connection between the aluminum strip and the main grid through infrared heating. Bonding of wire 301.

[0073] In this embodiment, the lamination packaging process of the battery adopts a pressure of 100 kaPa and vacuumizes for 10 minutes, and the materials used are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com