A processing method for producing green tea powder by using fresh summer and autumn tea leaves

A processing method and technology of green tea powder, which is applied in the field of rapid production of green tea powder, can solve the problems of uneven greening leaves, tea damage, serious precipitation, etc., to protect the color of tea leaves and various nutritional and health components, and strengthen nutrition and health care Efficacy, the effect of prolonging the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

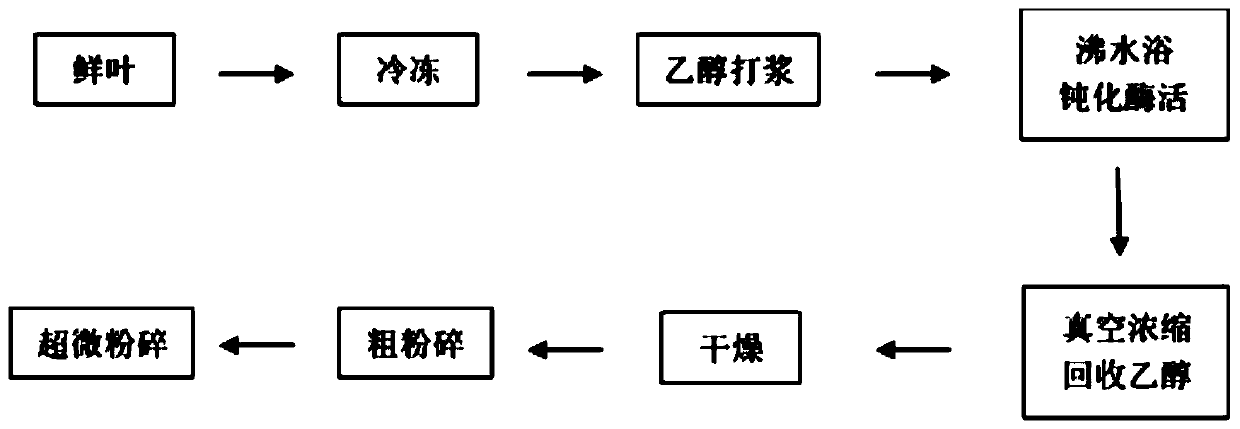

Method used

Image

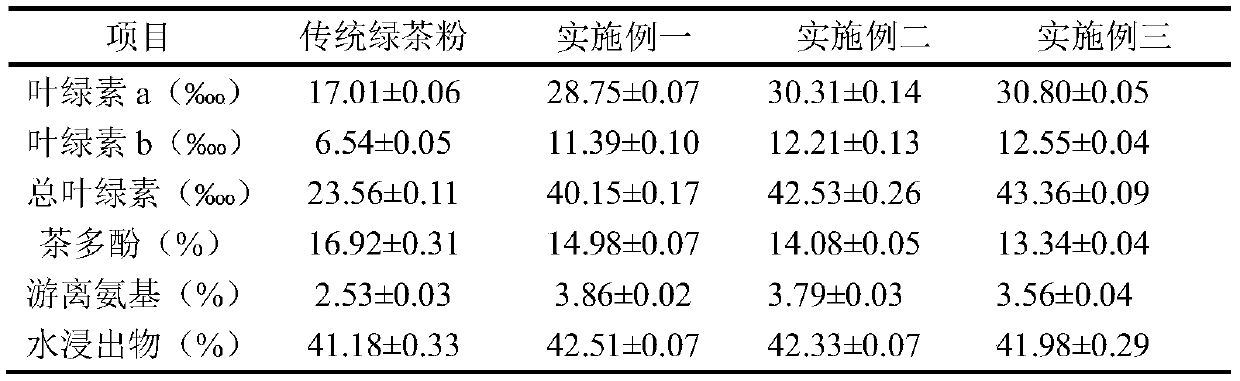

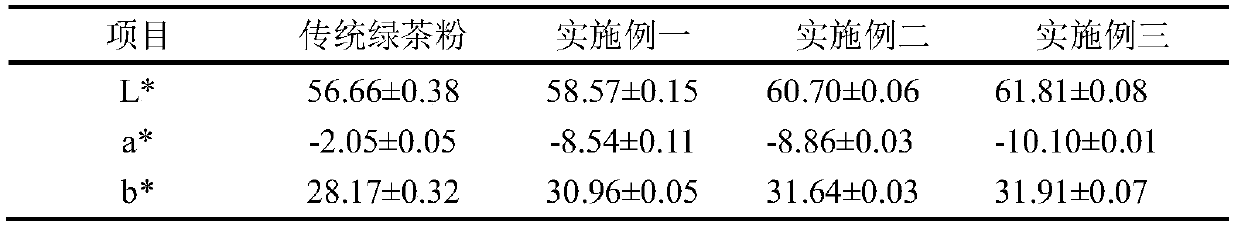

Examples

Embodiment 1

[0027] A processing method for rapidly producing green tea powder by utilizing the fresh leaves of summer and autumn tea, the steps of which are:

[0028] A. Select new shoots, one bud, two or three leaves of Fuding Dabai tea tree that was born in that year;

[0029] B. Spread naturally for 5 hours, freeze at -20°C, take 100g of frozen leaves for each portion, add 200ml of 95% (v / v) edible alcohol, put them into a beater, set the room temperature at 10°C, beat for 5min, until the tea leaves become tea pulp ;

[0030] C. Pack the tea homogenate after beating into 1L Erlenmeyer flasks, limited to 1 / 3 of the container capacity, seal with plastic wrap, and insert a glass rod into the seal;

[0031] D. Put the Erlenmeyer flask into boiling water at 100°C. The water surface is submerged in the tea homogenate surface. The enzyme activity is inactivated in the boiling water bath, and the glass rod is stirred for 3 minutes. Take it out, put it in cold water and cool to room temperatur...

Embodiment 2

[0040] A processing method for rapidly producing green tea powder by utilizing the fresh leaves of summer and autumn tea, the steps of which are:

[0041] A. Select new shoots, one bud, two or three leaves of Fuding Dabai tea tree that was born in that year;

[0042] B. Spread naturally for 5 hours, freeze at -20°C, store for 2 months, take 100g of frozen leaves for each portion, add 200ml of 95% edible alcohol, put them into a beater, set the room temperature at 15°C, beat for 5min, until the tea leaves become tea pulp;

[0043] C. Pack the tea homogenate after beating into 1L Erlenmeyer flasks, limited to 1 / 3 of the container capacity, seal with plastic wrap, and insert a glass rod into the seal;

[0044] D. Put the Erlenmeyer flask into boiling water at 100°C, the water surface is submerged in the tea homogenate surface, inactivate the enzyme activity in a boiling water bath, stir with a glass rod for 3 minutes, take it out, put it in cold water and cool to room temperatur...

Embodiment 3

[0053] A processing method for rapidly producing green tea powder by utilizing the fresh leaves of summer and autumn tea, the steps of which are:

[0054] A. Select the new shoot of Fuding Dabai tea tree, one bud and four leaves;

[0055] B. Spread naturally for 4 hours, freeze at -20°C, take 100g of frozen leaves for each portion, add 200mL of 95% edible alcohol, put them into a beater, keep the room temperature at 20°C, beat for 5min, until the tea leaves become tea pulp;

[0056] C. Pack the tea homogenate after beating into 1L Erlenmeyer flasks, limited to 1 / 3 of the container capacity, seal with plastic wrap, and insert a glass rod into the seal;

[0057] D. Put the Erlenmeyer flask into boiling water at 100°C, the water surface is submerged in the tea homogenate surface, passivate the enzyme activity in a boiling water bath, stir with a glass rod for 3.5 minutes, take it out, put it in cold water and cool to room temperature;

[0058] E, transfer the tea homogenate to a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com