Amino acid based cryoprotectant for frozen peeled shrimps and ice glazing method

A cryoprotectant and amino acid technology, applied in food preservation, food science, application, etc., can solve problems such as moisture content reduction, product quality deterioration, protein denaturation, etc., to inhibit ice crystal recrystallization, weaken oxidation, reduce The effect of oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

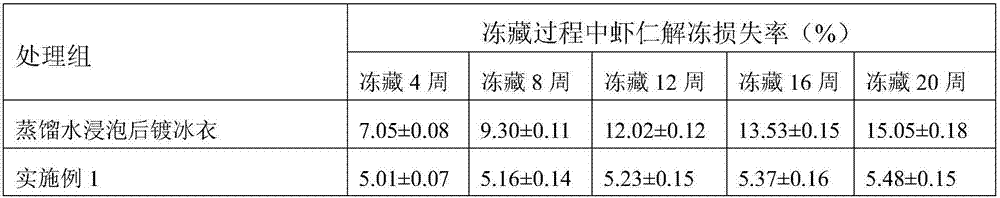

Embodiment 1

[0018] The ice coating method of the frozen shrimp of the present embodiment may further comprise the steps:

[0019] 1) Prepare the cryoprotectant according to the following mass concentration components: arginine mass concentration 1.15%, lysine mass concentration 0.75%, glycine mass concentration 0.6%, NaCl mass concentration 1.75%, after preparing the solution, adjust the system The pH value is 8.7;

[0020] 2) Vacuum tumbling process: at a temperature of 1°C, mix the shrimp with the cryoprotectant prepared above at a mass ratio of 2:1 for vacuum tumbling for 7 minutes, then drain the shrimp for 50 minutes;

[0021] 3) Prepare ice coat solution: algin oligosaccharide (polymerization degree 3) mass concentration 0.75%, lactitol mass concentration 0.6%, carboxymethyl cellulose (substitution degree 0.92) mass concentration 0.07%, stable chlorine dioxide mass concentration Concentration 0.17%;

[0022] 4) Ice-coating: Immerse the vacuum-tumbled shrimps in the ice-coating sol...

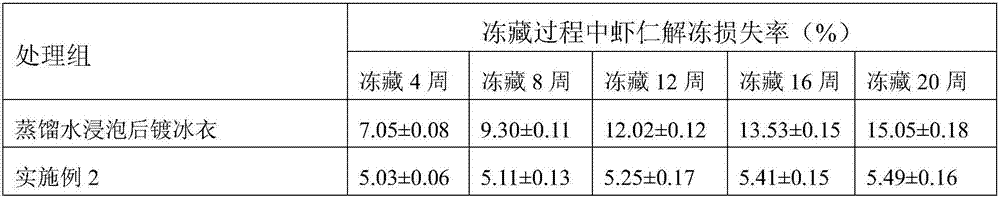

Embodiment 2

[0027] The ice coating method of the frozen shrimp of the present embodiment may further comprise the steps:

[0028] 1) prepare the cryoprotectant according to the following mass concentration components: arginine mass concentration 0.8%, lysine mass concentration 1.0%, glycine mass concentration 0.8%, NaCl mass concentration 1.5%, after preparing the solution, adjust The pH value of the system is 8.5;

[0029] 2) Vacuum tumbling process: at a temperature of 2°C, mix the shrimp with the cryoprotectant prepared above at a mass ratio of 1:1 for vacuum tumbling for 5 minutes, then drain the shrimp for 80 minutes;

[0030] 3) Prepare ice coat solution: algin oligosaccharide (polymerization degree 4) mass concentration 0.5%, lactitol mass concentration 0.8%, carboxymethyl cellulose (substitution degree 1.0) mass concentration 0.08%, stable chlorine dioxide mass concentration Concentration 0.08%;

[0031] 4) Ice-coating: Immerse the vacuum-tumbled shrimp in the ice-coating soluti...

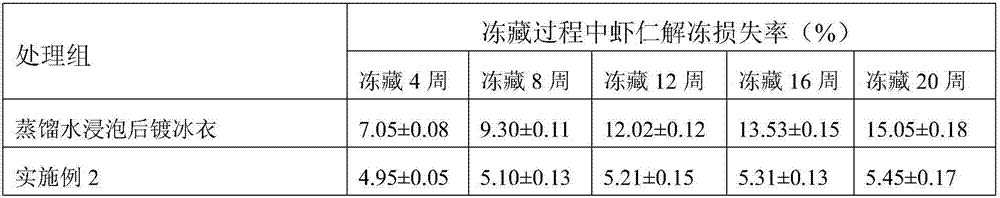

Embodiment 3

[0036] The ice coating method of the frozen shrimp of the present embodiment may further comprise the steps:

[0037] 1) prepare the cryoprotectant according to the following mass concentration components: arginine mass concentration 1.5%, lysine mass concentration 0.5%, glycine mass concentration 0.4%, NaCl mass concentration 2.0%, after preparing the solution, adjust The pH value of the system is 9.0;

[0038] 2) Vacuum tumbling process: at a temperature of 0°C, mix the shrimp with the cryoprotectant prepared above at a mass ratio of 3:1 for vacuum tumbling for 10 minutes, then drain the shrimp for 20 minutes;

[0039] 3) Preparation of ice coat solution: algin oligosaccharide (polymerization degree 2) mass concentration 1.0%, lactitol mass concentration 0.4%, carboxymethyl cellulose (substitution degree 0.85) mass concentration 0.05%, stable chlorine dioxide Mass concentration 0.26%;

[0040] 4) Ice-coating: Immerse the vacuum-tumbled shrimps in the above-prepared ice-coa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Chewiness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com