Vanadium-doped bismuth phosphate/attapulgite nanocomposite as well as preparation method and application thereof

A technology of nanocomposite materials and attapulgite, which is applied in chemical instruments and methods, refined hydrocarbon oil, chemical/physical processes, etc., can solve the problems of high temperature hydrogen, application limitations, and low utilization rate of sunlight, and achieve environmental friendliness, Inexpensive, evenly loaded effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Weigh 0.4851g of bismuth nitrate, 0.0624g of sodium dihydrogen phosphate, 0.0702g of ammonium metavanadate, and 1g of attapulgite into 10ml of deionized water and stir thoroughly with ultrasonic waves, transfer the obtained dispersion to a microwave hydrothermal reaction kettle, and heat Incubate for 90 minutes, centrifuge, wash with water and absolute ethanol, and dry in an oven at 80°C to obtain BiP 1-x V x o 4 / ATP nanocomposite (x=0.6).

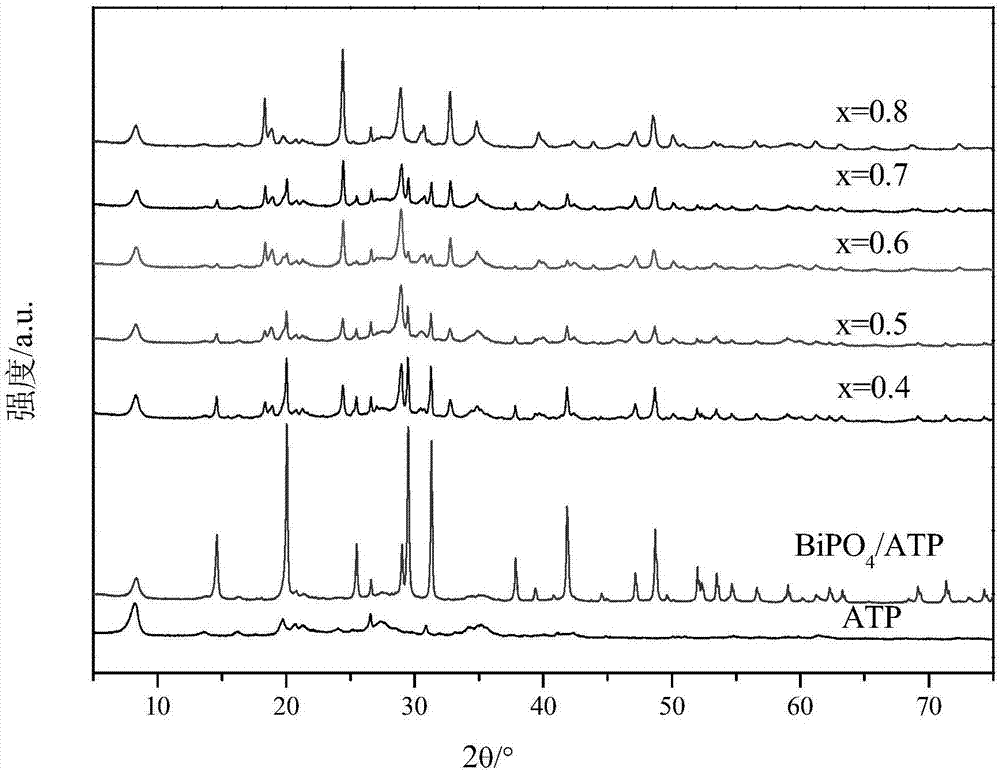

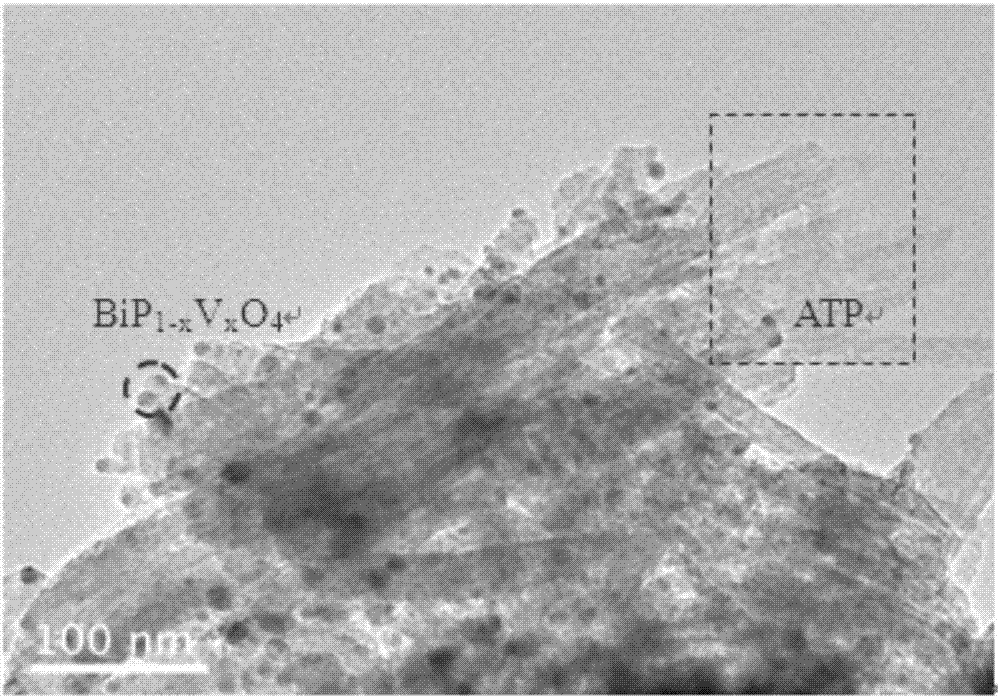

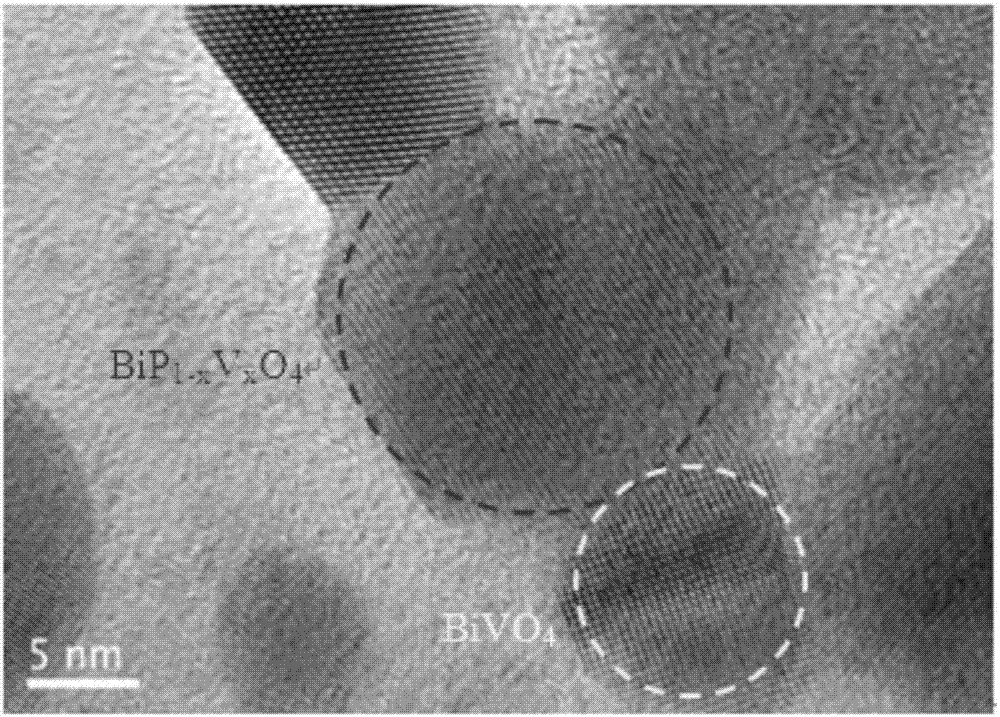

[0019] With reference to the process parameters of Example 1, the undoped bismuth phosphate / attapulgite composite material was prepared, and the X-ray powder diffraction was compared with the sample of the composite material obtained above, specifically as figure 1 As shown: the sample obtained above has a shift of the characteristic peak at 29.04°, indicating that the vanadium doping has entered the phosphorus lattice, and the characteristic peak of the attapulgite also appeared in the XRD of the composite material, indicating t...

Embodiment 2

[0031] Weigh 0.4851g of bismuth nitrate, 0.0936g of sodium dihydrogen phosphate, 0.0486g of ammonium metavanadate, and 1g of attapulgite into 10ml of deionized water in sequence and stir thoroughly with ultrasonic waves. Incubate for 90 minutes, centrifuge, wash with water and absolute ethanol, and dry in an oven at 80°C to obtain BiP 1-x V x o 4 / ATP nanocomposite (x=0.4). Subsequent testing was as in Example 1, and the desulfurization rate obtained was 90%.

Embodiment 3

[0033] Weigh 0.4851g of bismuth nitrate, 0.0780g of sodium dihydrogen phosphate, 0.0585g of ammonium metavanadate, and 1g of attapulgite into 10ml of deionized water in sequence and stir thoroughly with ultrasonic waves. Incubate for 90 minutes, centrifuge, wash with water and absolute ethanol, and dry in an oven at 80°C to obtain BiP 1-x V x o 4 / ATP nanocomposite (x=0.5). Subsequent detection was as in Example 1, and the obtained desulfurization rate was 93.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com