Acrylic ester containing perfluoropolyether chain and synthetic method thereof

A technology of perfluoropolyether and acrylate, which is applied in chemical instruments and methods, preparation of sulfonamide, preparation of carboxylic acid amide, etc., can solve problems such as adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] The structure of the acrylate containing perfluoropolyether chain synthesized in this embodiment is as follows:

[0061]

[0062] where Rf- is:

[0063]

[0064] 1) Synthesis of N-hydroxyethyl perfluoropolyether sulfonamide

[0065] Add 10.4g (0.1mol) of N-hydroxyethylethylenediamine, 50ml of anhydrous ether, and 50ml of methyl acetate into a 500ml reaction bottle, slowly add 142.4g (0.2mol) of all After the addition of methyl fluoropolyether sulfonate was completed, the ice-water bath was removed, and the reaction was continued for 10 hours. Then, the low-boiling components were removed by distillation with a rotary evaporator, and the intermediate N-hydroxyethyl perfluoropolyether sulfonamide was obtained after vacuum drying.

[0066] ) Synthesis of acrylates containing perfluoropolyether chains

[0067] Add 100ml of dichloromethane and 10.8g (0.105mol) of triethylamine to the above-mentioned reaction flask equipped with N-hydroxyethyl perfluoropolyether sulfo...

Embodiment 2

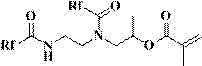

[0075] The structure of the acrylate containing perfluoroether chain synthesized in this embodiment is as follows:

[0076]

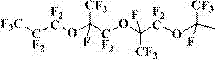

[0077] where Rf- is:

[0078]

[0079] 1) Synthesis of N-hydroxyethyl perfluoropolyetheramide

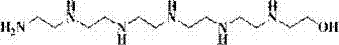

[0080] Add 14.7g (0.1mol) of N-hydroxyethyldiethylenetriamine and 100ml of dichloromethane into a 500ml reaction bottle, and slowly add 153.2g (0.3mol) of perfluoropolyether formic acid methyl in an ice-water bath while stirring After the addition of the ester, the ice-water bath was removed, and the reaction was continued for 10 hours, and then the low-boiling components were removed by distillation with a rotary evaporator, and the intermediate N-hydroxyethyl perfluoropolyetheramide was obtained after vacuum drying. The structure of ethyldiethylenetriamine is as follows:

[0081]

[0082] 2) Synthesis of acrylates containing perfluoropolyether chains

[0083] Add 100ml of anhydrous ether and 10.8g (0.105mol) of triethylamine to the above-mention...

Embodiment 3

[0092] The structure of the acrylate containing perfluoroether chain synthesized in this embodiment is as follows:

[0093]

[0094] where Rf- is:

[0095]

[0096] 1) Synthesis of N-(2-hydroxypropyl) perfluoropolyetheramide

[0097] Add 11.82g (0.1mol) N-(2-hydroxypropyl)-ethylenediamine and 100ml tetrahydrofuran into a 500ml reaction bottle, slowly add 138.03g (0.2mol) perfluoropolyether dropwise under ice-water bath while stirring Ethyl formate, the dropwise addition is completed, remove the ice-water bath, continue the reaction for 10h, then use the rotary evaporator to distill off the low boiling point components, and obtain the intermediate N-(2-hydroxypropyl) perfluoropolyetheramide after vacuum drying, wherein The N-(2-hydroxypropyl)-ethylenediamine structure used is as follows:

[0098]

[0099] 2) Synthesis of acrylates containing perfluoropolyether chains

[0100] Add 100ml of chloroform and 13.57g (0.105mol) of N,N-diisopropylethylamine to the reaction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com