A kind of graphene-filled anisotropic high thermal conductivity preformed adhesive tape and its preparation method

An anisotropic and graphene technology, applied in the direction of conductive adhesives, adhesives, adhesive types, etc., can solve the problems of weakening the effect of isotropic heat-conducting materials, discounting the heat-conducting effect of graphene, and having no requirements for thickness and size , to achieve the effect of facilitating large-scale application, controlling costs and ensuring profit margins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

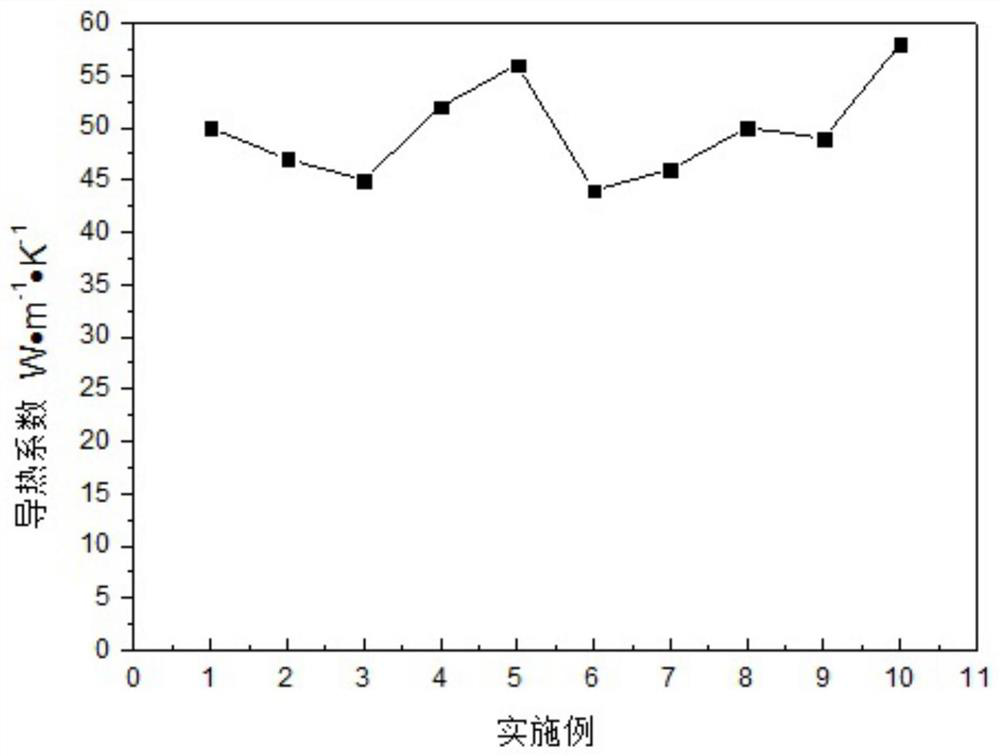

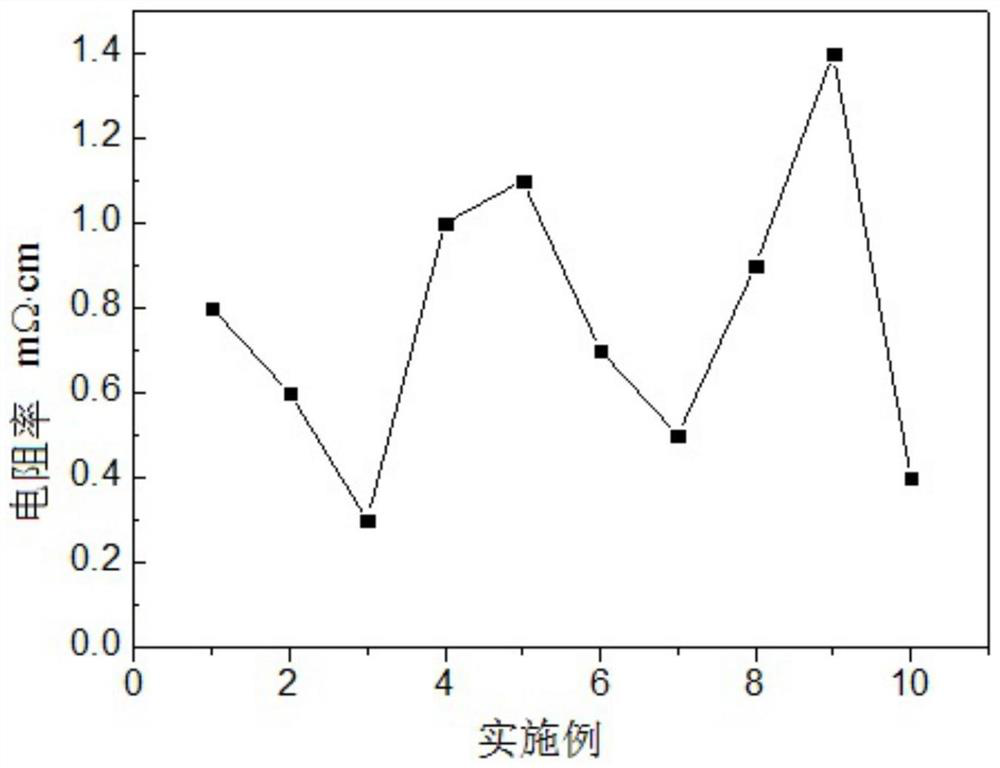

Embodiment 1

[0041] A graphene thermally conductive double-sided adhesive tape, mainly composed of graphene thermally conductive adhesive film and release paper, and release paper is applied on both sides of the adhesive film, and the thermally conductive adhesive film is mixed with the following components by weight and then baked Roast to get:

[0042]

[0043] 1. The synthesis method of modified silicone epoxy resin is:

[0044] Mix 30 parts of bisphenol A type epoxy resin with 30 parts of diluent xylene, then mix with 5 parts of γ-aminopropyltriethoxysilane, 0.2 parts of dibutyltin dilaurate and 30 parts of 955# silicone resin , reacted at 90 ° C for 1 h, distilled off xylene under reduced pressure, and obtained a uniform modified silicone epoxy resin under vacuum conditions.

[0045] 2. Graphene dispersion:

[0046] The graphene powder weighed according to the mass given in Table 1 is mixed with a silane coupling agent and a solvent, then emulsified using an emulsifier (speed 500...

Embodiment 2

[0054] A graphene thermally conductive double-sided adhesive tape, mainly composed of graphene thermally conductive adhesive film and release paper, and release paper is applied on both sides of the adhesive film, and the thermally conductive adhesive film is mixed with the following components by weight and then baked Roast to get:

[0055]

[0056] 1. The synthesis method of modified silicone epoxy resin is:

[0057] Mix 30 parts of bisphenol A type epoxy resin with 30 parts of diluent xylene, then mix with 3 parts of γ-aminopropyltriethoxysilane, 0.2 parts of dibutyltin dilaurate and 30 parts of 955# silicone resin , reacted at 90 ° C for 1 h, distilled off xylene under reduced pressure, and obtained a uniform modified silicone epoxy resin under vacuum conditions.

[0058] 2. Graphene dispersion:

[0059] The graphene powder weighed according to the mass given in Table 1 is mixed with a silane coupling agent and a solvent, then emulsified using an emulsifier (speed 500...

Embodiment 3

[0067] A graphene thermally conductive double-sided adhesive tape, mainly composed of graphene thermally conductive adhesive film and release paper, and release paper is applied on both sides of the adhesive film, and the thermally conductive adhesive film is mixed with the following components by weight and then baked Roast to get:

[0068]

[0069] 1. The synthesis method of modified silicone epoxy resin is:

[0070] Mix 30 parts of bisphenol A type epoxy resin with 30 parts of diluent xylene, then mix with 3 parts of γ-aminopropyltriethoxysilane, 0.3 parts of dibutyltin dilaurate and 30 parts of 955# silicone resin , reacted at 90 ° C for 1 h, distilled off xylene under reduced pressure, and obtained a uniform modified silicone epoxy resin under vacuum conditions.

[0071] 2. Graphene dispersion:

[0072] Graphene powder is mixed with silane coupling agent and solvent according to the mass weighing given in table 1, then use emulsifier emulsification (speed 5000 revs / m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com