Preparation method of nanocrystal containing manganese and fluoride compounds

A technology of nanocrystals and manganese fluoride, which is applied in the field of synthesis of manganese-containing fluoride nanocrystals, can solve the problems of high crystallinity and small size, and achieve the effect of easy operation and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

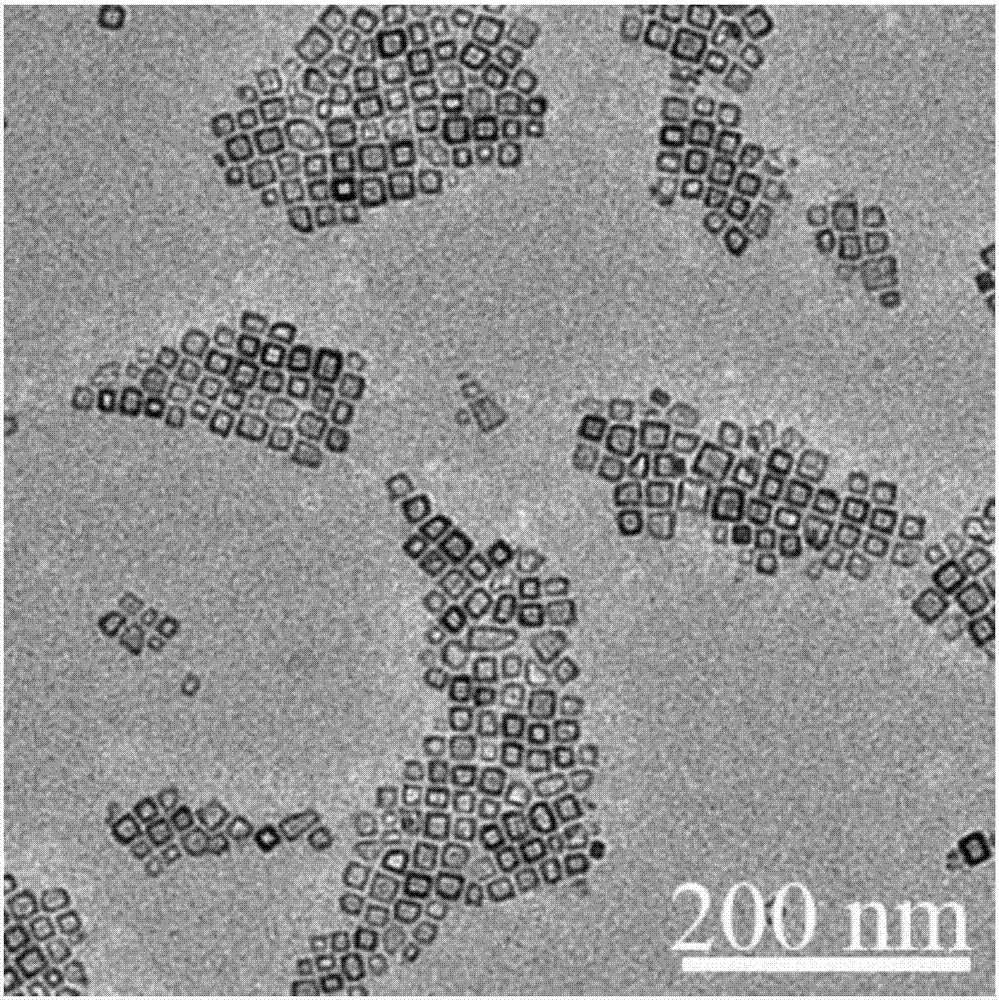

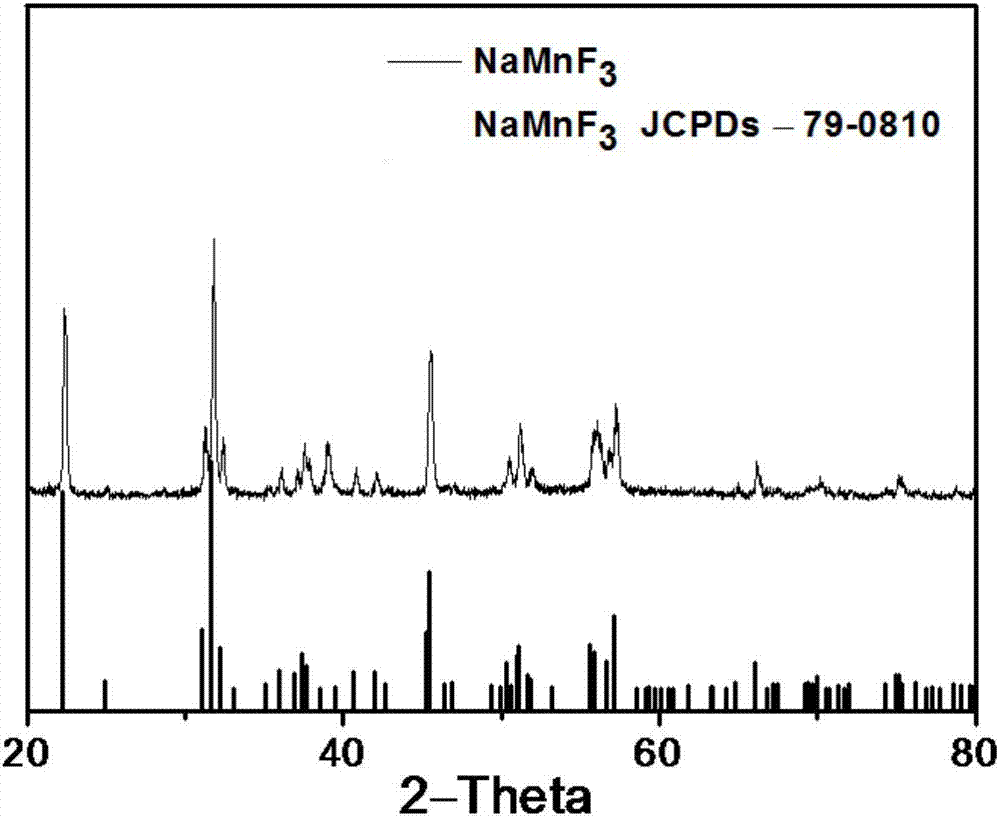

[0047] Embodiment 1: prepare the NaMnF of hollow structure 3 nanocrystal

[0048] Completely dissolve 0.03mol sodium hydroxide in 4mL water and 9mL absolute ethanol, add 20mL oleic acid, stir for 10min; then add 1mL0.5mmol / mL manganese chloride aqueous solution and 4mL0.375mmol / mL potassium fluoride aqueous solution in sequence , stirred for 1h to get NaMnF 3 The nanocrystal precursor was then transferred to a 50mL reactor and reacted at 160°C for 24h. After the reaction, cool to room temperature, add absolute ethanol to precipitate the product, centrifuge at 8000rpm for 15min, and wash the precipitate obtained by centrifugation with water and absolute ethanol several times to obtain hollow NaMnF 3 nanocrystals. figure 1 Hollow NaMnF prepared for this example 3 TEM photographs of nanocrystals, figure 2 Hollow NaMnF prepared for this example 3 The powder X-ray diffraction spectrum of nanocrystals, its diffraction peaks are similar to those of NaMnF 3 The standard diffra...

Embodiment 2

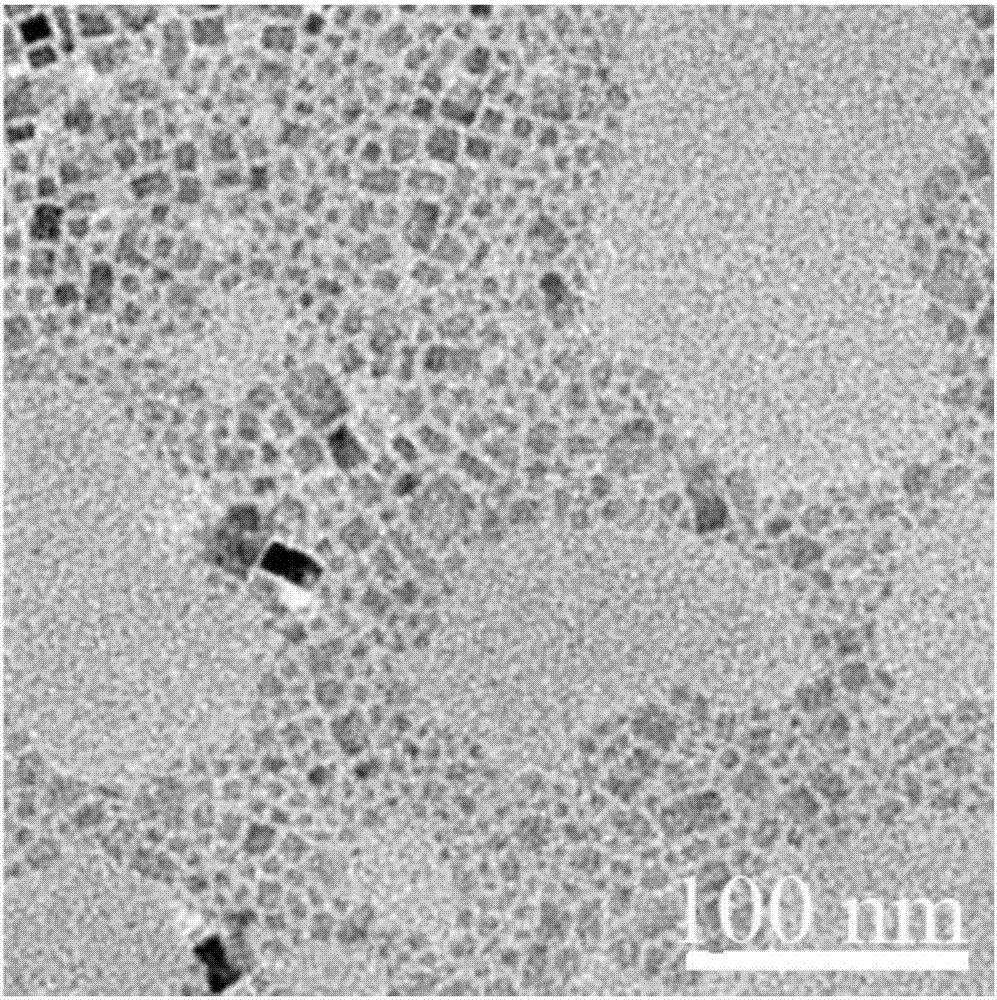

[0049] Embodiment 2: prepare the KMnF of solid structure 3 nanocrystal

[0050] The steps of this embodiment are basically the same as in Example 1, except that 0.03 mol of potassium hydroxide is used to replace 0.03 mol of sodium hydroxide. image 3 Solid KMnF prepared for this example 3 TEM photographs of nanocrystals, Figure 4 Solid KMnF prepared for this example 3 The powder X-ray diffraction spectrum of nanocrystals, its diffraction peaks are consistent with the standard diffraction peaks of KMnF3, proving that the obtained product is pure KMnF 3 .

Embodiment 3

[0051] Example 3: Preparation of solid KMnF doped with a single rare earth ion 3 nanocrystal

[0052] Dissolve 0.03mol potassium hydroxide completely in 4mL water and 9mL absolute ethanol, then add 20mL oleic acid, stir for 10min, then add 1mL 0.5mmol / mL manganese chloride and neodymium chloride (molar ratio Mn:Nd=49 : 1) mixed aqueous solution and 4mL 0.5mmol / mL potassium fluoride aqueous solution, stirred for 1h to obtain KMnF doped with rare earth ion neodymium 3 The nanocrystal precursor was then transferred to a 50mL reactor and reacted at 160°C for 24h. After the reaction, cool to room temperature, centrifuge the reaction system at 11,000 rpm for 15 minutes, and wash the product obtained after high-speed centrifugation with cyclohexane and absolute ethanol several times. Figure 5 The solid KMnF doped rare earth ion neodymium prepared for this embodiment 3 TEM photographs of nanocrystals, Figure 6 The solid KMnF doped rare earth ion neodymium prepared for this embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com