Preparation method for growing ABX3-type perovskite thin film through single-step in-situ flash method

A technology of perovskite and flash evaporation is applied in the preparation of perovskite thin films. The field of perovskite thin films prepared by deposition process can solve the problem that the rate is not suitable for large-scale production, cannot be mass-produced, and single-crystal silicon is time-consuming. Energy consumption and other issues, to achieve the effect of a wide selection of substrates, good crystal quality of the film, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

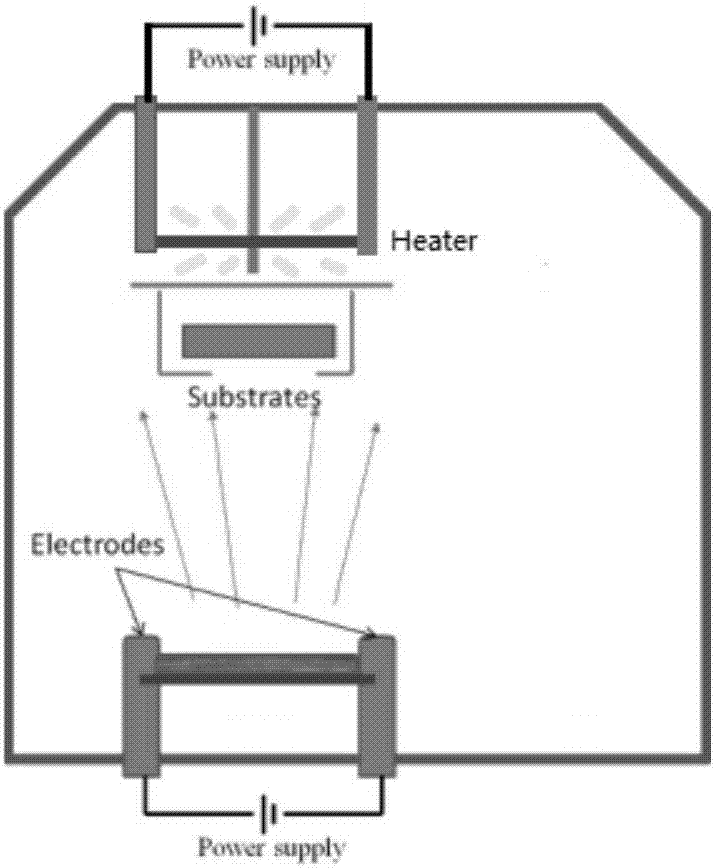

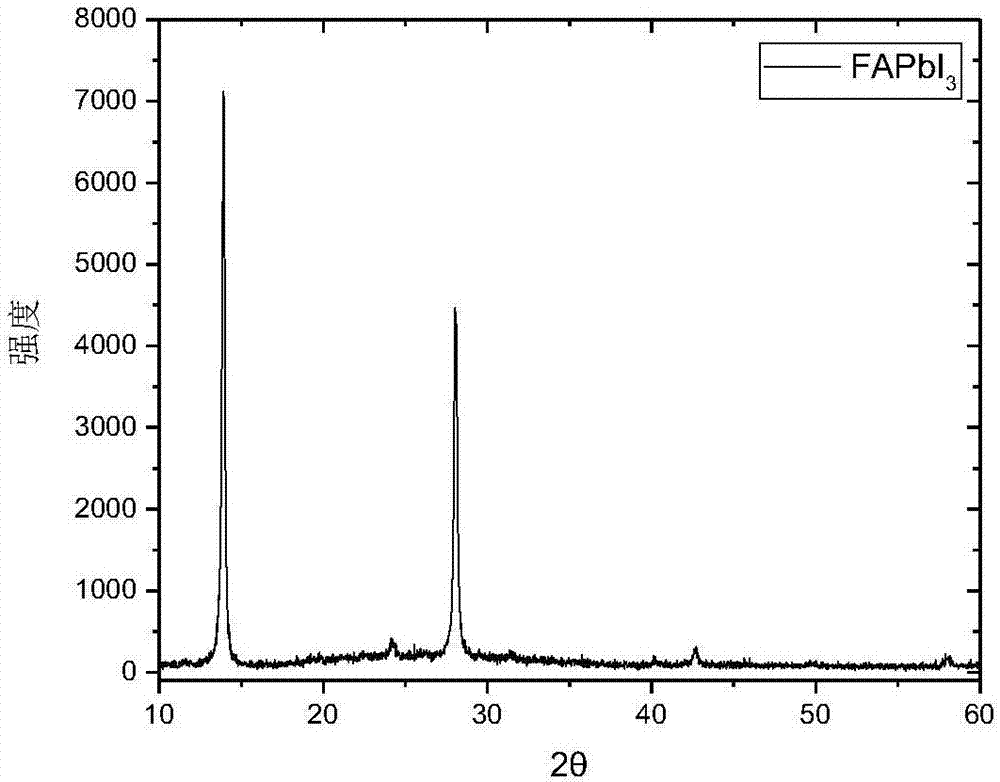

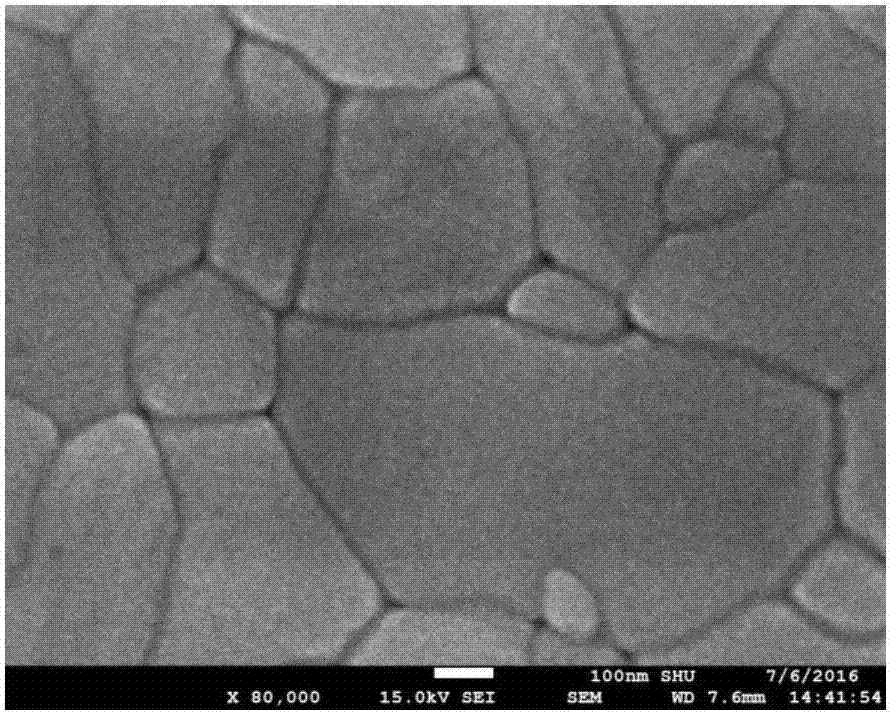

[0026] In this example, see figure 1 , a single-step in situ flash method for growing FAPbI 3 The preparation method of perovskite thin film, comprises the steps:

[0027] a. Substrate pretreatment:

[0028] F-doped SnO 2 FTO, the transparent conductive glass SnO 2 : F as a deposition substrate, the pretreatment steps are:

[0029] First use zinc powder and dilute hydrochloric acid to etch the FTO transparent conductive glass substrate to form the required pattern, then rinse it with deionized water, and then use Triton to clean the substrate surface to remove the stains on the substrate surface, and then use deionized water to clean the surface of the substrate. Wash with water, rinse off the residual triton on the surface of the substrate, then use acetone and ethanol to ultrasonically clean for 15 minutes, then rinse the surface of the FTO transparent conductive glass substrate with deionized water, and then dry the FTO transparent conductive glass substrate , and fina...

Embodiment 2

[0037] This embodiment is basically the same as Embodiment 1, especially in that:

[0038] In this example, a single-step in situ flash method for growing FAPbI 3 The preparation method of perovskite thin film, comprises the steps:

[0039] a. Substrate pretreatment:

[0040] The Si substrate is adopted, and the Si substrate is used as a deposition substrate. The pretreatment steps are:

[0041] The Si substrate is cleaned with deionized water, and then the Si substrate is soaked in concentrated sulfuric acid with a concentration of 98.3% by mass percentage, then the Si substrate is taken out, and the residual sulfuric acid on the Si substrate is cleaned with deionized water, and then the Si substrate is treated. Drying is carried out, and finally the surface of the Si substrate is treated with microwave plasma for 10 minutes to obtain a clean silicon substrate;

[0042] Then take 5mg PCBM and dissolve it in 1ml of chlorobenzene, stir at room temperature for 12h, make it fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com