Flame-retardant neosinocalamus affinis and cryptomeria fortunei composite board manufacturing method

A manufacturing method and composite board technology, applied in the direction of manufacturing tools, chemical instruments and methods, and other plywood/plywood appliances, can solve the problem of low mechanical indicators such as compressive strength along the grain, flexural strength, and flexural modulus of elasticity. And problems such as low hardness and low processing efficiency, to achieve the effect of improving the appearance, improving the safety factor and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

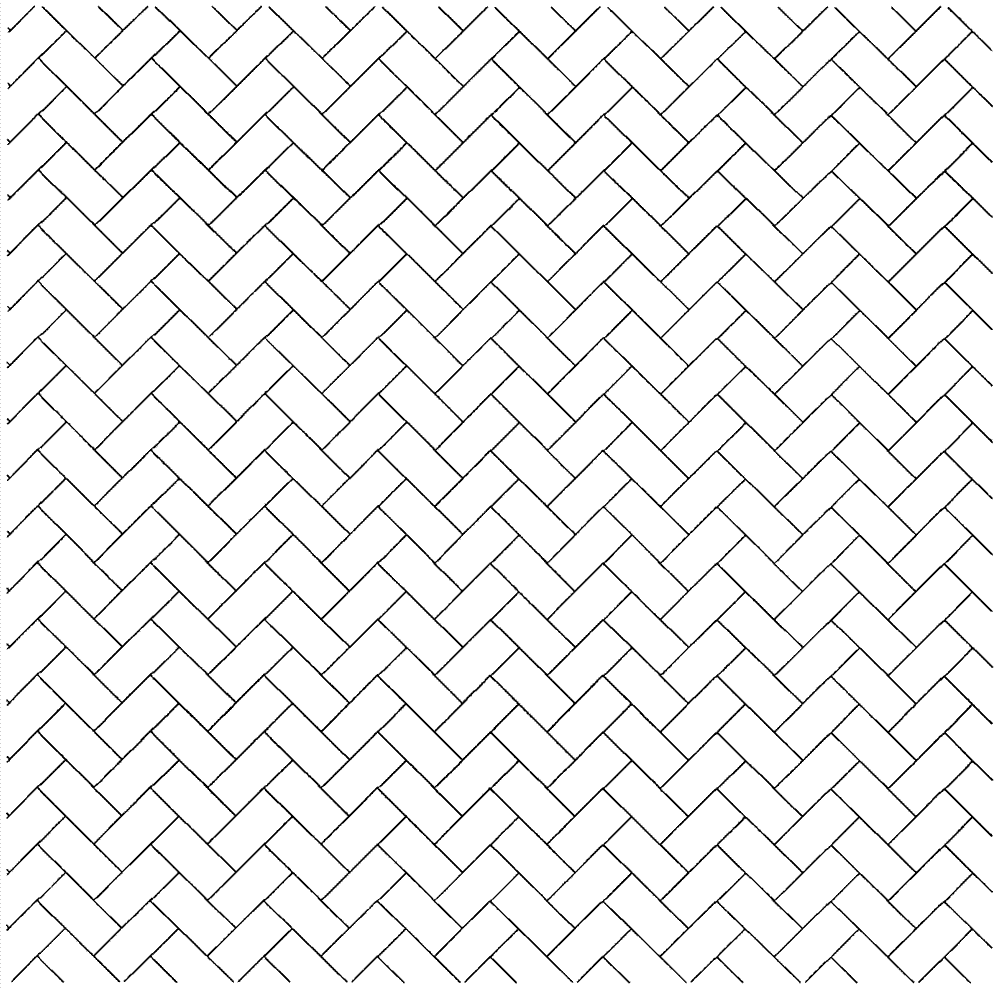

[0030] (1) Compassionate Bamboo Timber: Cut Cizhu into bamboo sections with a length of (50±2) CM, split the bamboo sections longitudinally into bamboo strips with a string length of (10±2)MM, and cut the bamboo sections with a bamboo knife. Shave off the green and bamboo yellow, pre-press for 4 minutes on a hot-pressing machine with a set hot-pressing temperature of 100°C and a pressure of 8 MPa, and weave the hot-pressed bamboo strips in a horizontal and vertical manner to make a length and width of (50 ±2) CM bamboo mat (such as figure 1 shown).

[0031] (2) Cedar lumber: rotary cut cedar logs into veneers with a thickness of 1MM and a length and width of (50±2)CM.

[0032] (3) Flame retardant treatment of materials: immerse the bamboo mat and cedar veneer in liquid flame retardant for 45 minutes, and dry them in a wood dryer until the moisture content is 11%. The ratio is: dicyandiamide: phosphoric acid: boric acid: sodium alkylsulfonate: pentaerythritol = 0.095: 0.102: ...

Embodiment 2

[0038] (1) Compassionate Bamboo Timber: Cut Cizhu into bamboo sections with a length of (50±2) CM, split the bamboo sections longitudinally into bamboo strips with a string length of (10±2)MM, and cut the bamboo sections with a bamboo knife. Shave off the green and bamboo yellow, pre-press for 5 minutes on a hot-pressing machine with a set hot-pressing temperature of 100°C and a pressure of 8 MPa, and weave the hot-pressed bamboo strips in a horizontal and vertical manner to make a length and width equal to (50 ±2) CM bamboo mat (such as figure 1 shown).

[0039] (2) Cedar lumber: rotary cut cedar logs into veneers with a thickness of 1MM and a length and width of (50±2)CM.

[0040] (3) Flame retardant treatment of materials: Soak bamboo mats and cedar veneers in liquid flame retardant for 45 minutes, and dry them in a wood dryer until the moisture content is 10%. The ratio is: dicyandiamide: phosphoric acid: boric acid: sodium alkylsulfonate: pentaerythritol = 0.095: 0.102:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com