Nickel-based catalyst and its preparation method and application

A nickel-based catalyst and hydrogenation reaction technology, applied in the field of catalysis, to achieve the effects of strong anti-poisoning ability, reduced separation pressure, and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

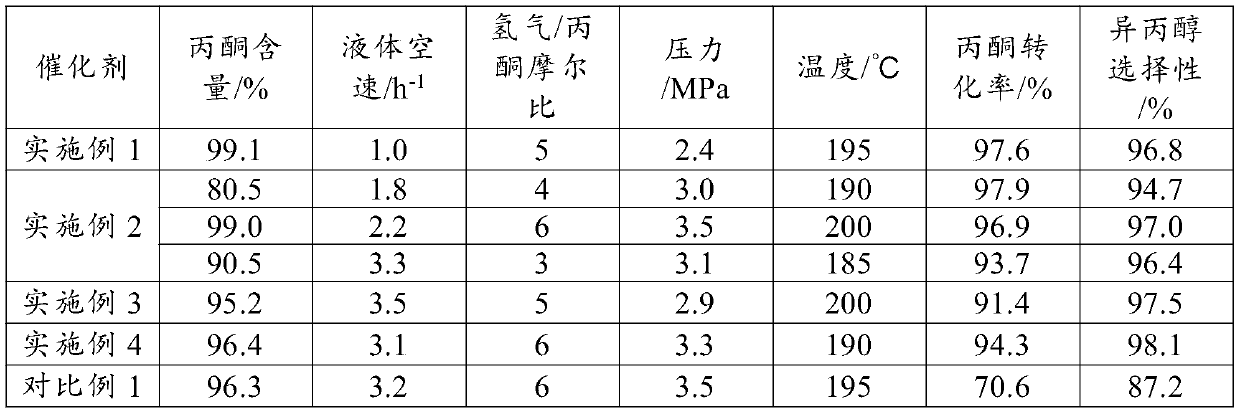

Examples

Embodiment 1

[0032] Accurately weigh 400 grams of nickel with a purity greater than 99%, 500 grams of aluminum with a purity greater than 99%, 50 grams of copper with a purity greater than 99%, 40 grams of iron with a purity greater than 99%, and 10 grams of manganese with a purity greater than 99%, and mix well Finally, the metal mixture is obtained, and the metal mixture is melted in an intermediate frequency electric furnace at 1650 ° C for 0.5 hours, poured into a mold, cooled by quenching, crushed by a jaw crusher, and sieved to obtain a particle size of 3 -6mm alloy particles.

[0033] Then, get 200g of the alloy particles obtained above, and put it in a quartz glass tube with an inner diameter of 60mm, and put a concentration of 1.0wt% KOH solution (the conductivity of water used to prepare the KOH solution is 50 μs / cm) at a space velocity of 12h -1 The speed flows from the bottom of the quartz glass tube through the bed of alloy particles and then flows out from the top. The bed t...

Embodiment 2

[0035] Accurately weigh 420 grams of nickel with a purity greater than 99%, 480 grams of aluminum with a purity greater than 99%, 60 grams of copper with a purity greater than 99%, 30 grams of iron with a purity greater than 99%, and 10 grams of manganese with a purity greater than 99%, and mix well Finally, the metal mixture is obtained, and the metal mixture is melted in an intermediate frequency electric furnace at 1650°C for 0.4 hours, poured into a mold, cooled in a stepwise manner, crushed by a hammer crusher, and sieved to obtain a particle size of 3- 6mm alloy particles.

[0036] Then, get 200g of the alloy particles obtained above, place the inner diameter in a quartz glass tube of 60mm, and put the concentration of 0.8wt% KOH solution (the conductivity of water used to prepare the KOH solution is 100μs / cm) at a space velocity of 15h -1 The speed flows from the bottom of the quartz glass tube through the bed of alloy particles and then flows out from the top. The bed...

Embodiment 3

[0038] Accurately weigh 400 grams of nickel with a purity greater than 99%, 550 grams of aluminum with a purity greater than 99%, 30 grams of copper with a purity greater than 99%, 10 grams of iron with a purity greater than 99%, and 10 grams of manganese with a purity greater than 99%, and mix well Finally, the metal mixture is obtained, and the metal mixture is melted in an intermediate frequency electric furnace at 1550°C for 0.3 hours, poured into a mold, cooled in a stepwise manner, and passed through a jaw crusher and a ball mill to obtain an alloy with a particle size of less than 200 mesh powder, then add water, pseudo-boehmite and binder, extrude into strips, dry and roast to obtain rod-shaped alloy particles with a diameter of 3mm and a length of 2-6mm.

[0039] Then, 200 g of the metal alloy particles obtained above are placed in a quartz glass tube with an internal diameter of 60 mm, and the concentration is 1.2 wt % KOH solution (the conductivity of water used to p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com