A kind of two-dimensional colloidal crystal film and preparation method thereof

A two-dimensional colloid and crystal film technology, applied in the field of nanomaterials, can solve the problems of uneven thickness, no enhancement of luminous performance, and insufficient density of single-layer films, and achieve the effect of rapid preparation method and good universality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The invention provides a method for preparing a two-dimensional colloidal crystal film, which may include:

[0032] (1) obtaining a colloidal suspension of layered rare earth hydroxide nanosheets;

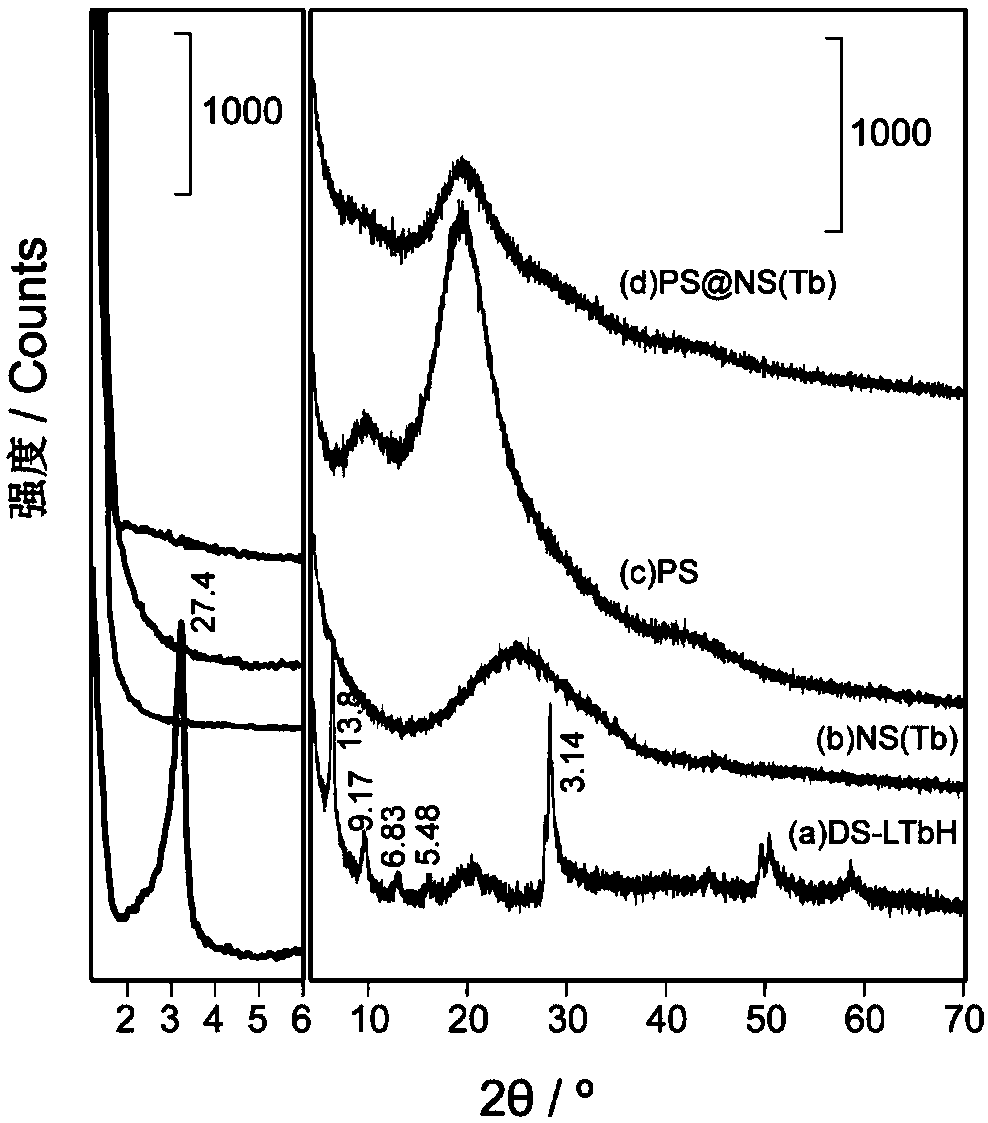

[0033] In a specific embodiment, the rare earth element in the layered rare earth hydroxide nanosheets can be europium, terbium and / or dysprosium, and in another specific embodiment, the layered rare earth hydroxide can be ten Dialkyl sulfate (DSˉ) intercalated rare earth terbium hydroxide, referred to as DSˉ-LTbH. The preparation method of layered rare earth hydroxide and the method of dispersing it into nanosheet colloidal suspension have been reported in the prior art, for example in the literature Yushuang Zhao; Ji-Guang Li; Mengxi Guo; Xiaojing Yang, Structural DS — LTbH (DSˉ intercalated rare earth terbium hydroxide), DS -- The preparation method of LEuH (DS-intercalated rare earth europium hydroxide) and its dispersion into nanosheet colloidal suspension. The pres...

Embodiment 1

[0042] Embodiment 1DSˉ-LTbH and the preparation of its nanosheet suspension

[0043] 1), the preparation of DSˉ-LTbH

[0044] 0.453g (1mmol) Tb (NO 3 ) 3 ·6H 2 O, 0.8651g (3mmol) SDS (sodium dodecyl sulfate) and 0.1402g (1mmol) HMT (hexamethylenetetramine) were added to a 100mL hydrothermal reaction kettle, and 80mL exhaust water was added, and after stirring , sealed and placed in an oven, kept at 90-120°C for 9-12 hours, cooled to room temperature, centrifuged at 10,000-15,000 rpm for 3-5 minutes, and the obtained precipitate was washed 3 times with degassed water and 2 times with absolute ethanol, and then 25- Dry at 40°C for 12 hours to obtain DSˉ-LTbH powder.

[0045] 2), preparation of suspension of DSˉ-LTbH nanosheets

[0046] Disperse 0.1 g of the above-prepared DSˉ-LTbH powder in a conical flask filled with 50 ml of formamide, pass N 2 20 minutes. Then seal the Erlenmeyer flask and keep it in a 40°C incubator for 3 days to obtain a colloidal suspension of DSˉ-...

Embodiment 2

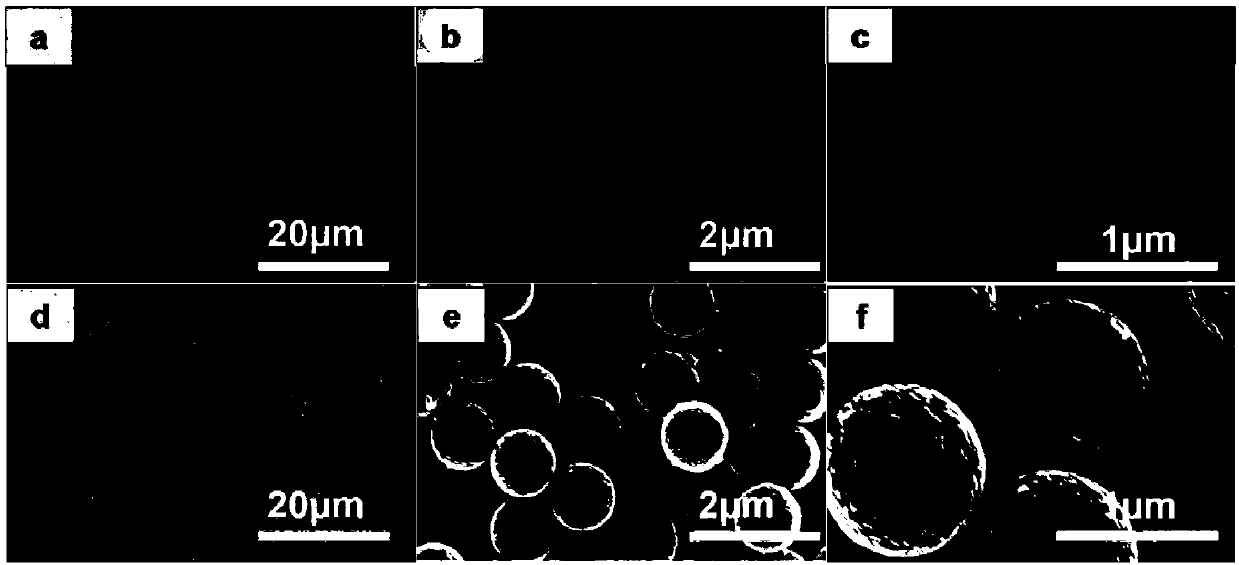

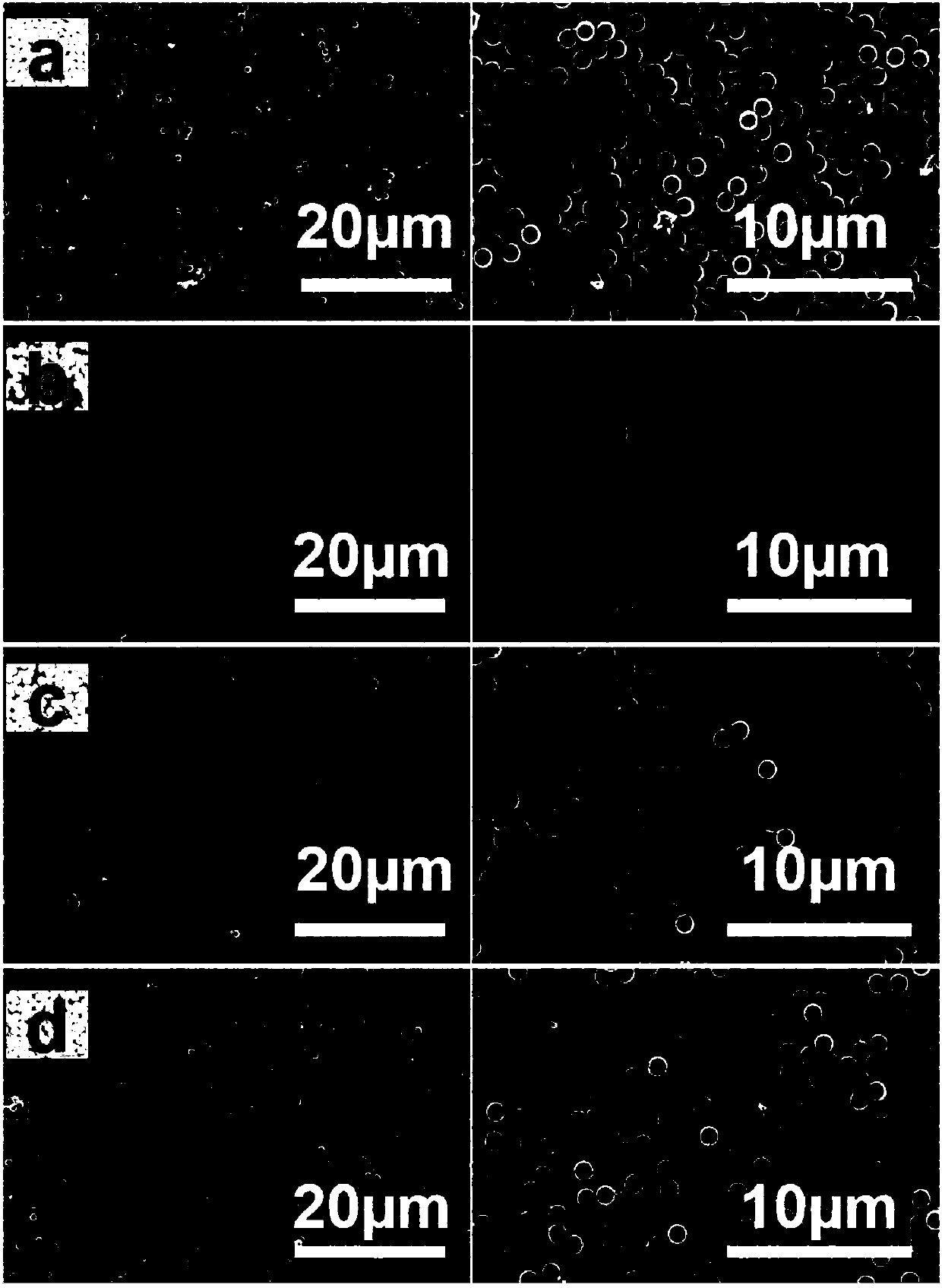

[0047] The preparation of embodiment 2 colloidal spheres

[0048] 1) Preparation of spherical core

[0049] Add 0.2g polystyrene nanospheres (particle size 980nm, manufacturer and model of Shanghai Huizhi Biotechnology Co., Ltd.) into 50mL aqueous solution of polyallylamine hydrochloride (the concentration of polyallylamine hydrochloride is 1g / L), stirred for 40 minutes, and after filtering through a microporous membrane, the solid product was washed 3 times with ultrapure water; then the solid product was placed in an aqueous solution of 50mL sodium polystyrene sulfonate (polystyrene The concentration of sodium sulfonate is 1 g / L), stirred for 40 minutes, filtered through a microporous membrane (0.45 μm), washed 3 times with ultrapure water, and the spherical core can be obtained.

[0050] 2), preparation of colloidal spheres

[0051] 0.1 g spherical core was immersed in 50 mL, 2 mg / mL suspension of DSˉ-LTbH nanosheets and mechanically stirred for 45 minutes to promote the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com