Method and device for preparing diisobutylene, triisobutylene and tetraisobutylene by isobutene polymerization

A technology of triisobutene and diisobutene, which is applied in the field of isobutene polymerization, can solve the problems of many by-product high polymers, difficulty in controlling the degree of polymerization, unstable operation, etc., achieve low raw material specification requirements, easy temperature control, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1, a kind of isobutene polymerization prepares the method for diisobutene, triisobutene and tetraisobutene, comprises the steps:

[0045] 1. Catalyst preparation steps;

[0046] The catalyst is composed of the following parts by weight, 10 parts of amorphous silicon aluminum, 20 parts of molecular sieve, 13 parts of magnesium oxide, 9 parts of sodium carbonate, 13 parts of activated carbon, 8 parts of basic aluminum sulfate, 8 parts of kaolin, 17 parts of boron, 15 parts of ferric oxide, 25 parts of nano zinc oxide particles, 8 parts of calcium oxide;

[0047] Described molecular sieve is the mixture of SAPO-11 molecular sieve and beta zeolite molecular sieve, and the mass ratio of SAPO-11 molecular sieve and beta zeolite molecular sieve is 1:2;

[0048] The particle size of the nano zinc oxide particles is 50-10nm, and the length is 80-30nm.

[0049]The relative crystallinity of the SAPO-11 molecular sieve is 98%, and the crystal particle size is 2.0 μm; ...

Embodiment 2

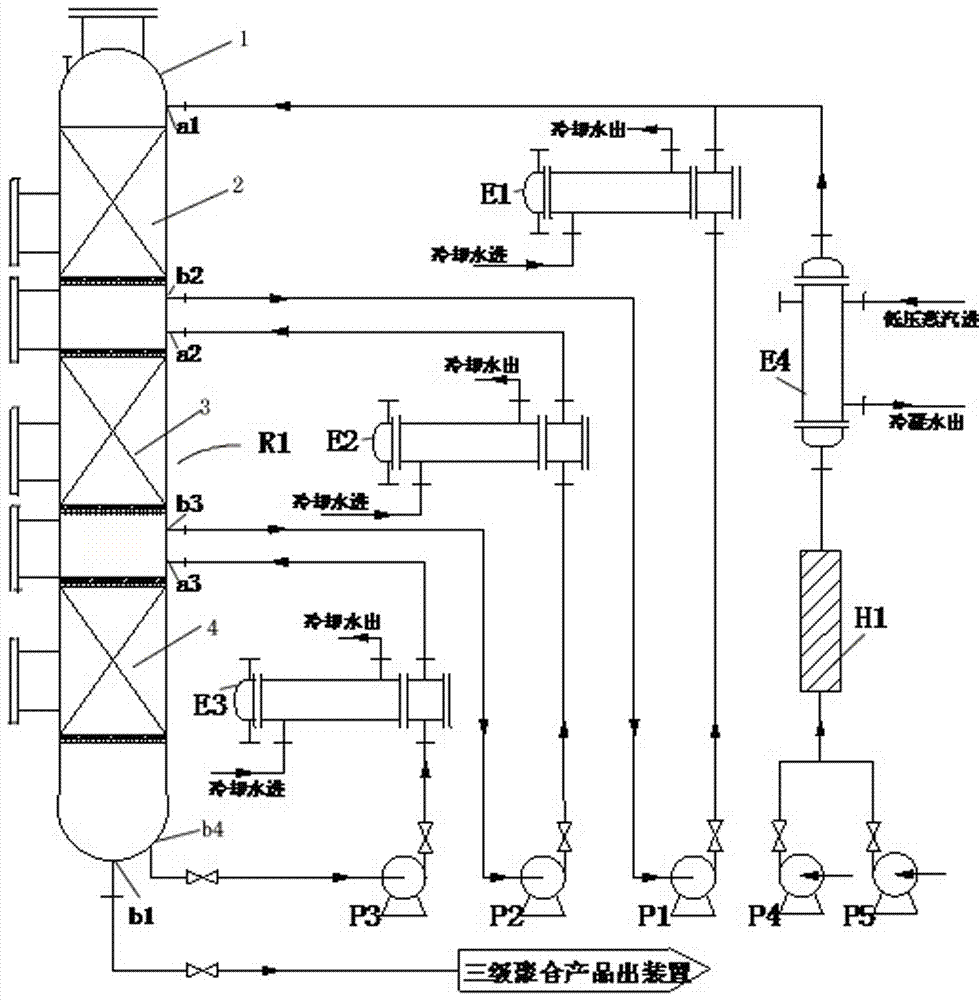

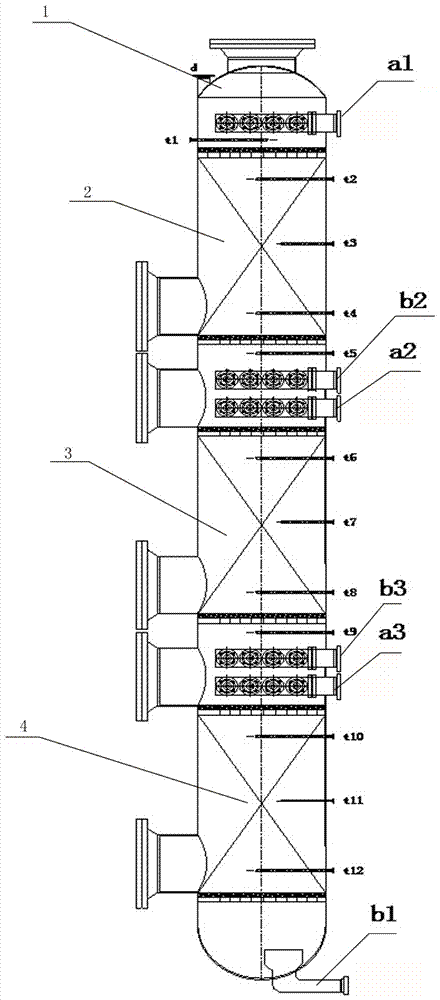

[0063] Example 2, such as figure 1 , figure 2 As shown, a device for preparing diisobutene, triisobutene and tetraisobutene by polymerization of isobutene includes an isobutene high-efficiency polymerization device R1, a primary product heat exchanger E1, a secondary product heat exchanger E2, and a tertiary product heat exchanger E3, Raw material preheater E4, primary product circulating pump P1, secondary product circulating pump P2, tertiary product circulating pump P3, polymerization inhibitor feeding pump P4, raw material pump P5, static mixer H1.

[0064] The isobutylene high-efficiency polymerization device R1 includes a tank body. The tank body 1 is respectively provided with a raw material inlet a1, a secondary polymerization crude product feed port a2, and a tertiary polymerization crude product feed port a3 from top to bottom on the tank body 1. From top to bottom, there are also first-level polymerization crude product outlet b2, second-level crude product outlet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com