A wear-resistant water-permeable brick for squares and a preparing method thereof

A square brick and cement technology, applied in the field of square bricks, can solve the problems of large waste of brick resources, failure to meet the performance of square bricks, poor frost resistance, etc., achieve good flexural and compressive strength, prevent urban heat island effect, reduce The effect of ambient temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

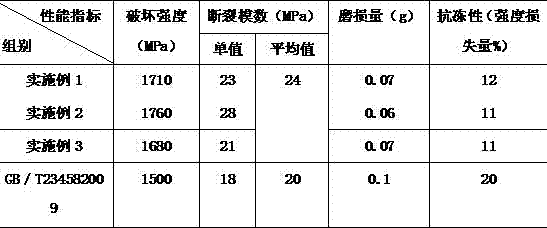

Examples

Embodiment 1

[0025] 1. Selection of raw materials

[0026] A wear-resistant and permeable square brick, comprising the following raw materials: 80kg of composite Portland cement, 40kg of attapulgite clay, 30kg of waste mine tailings, 20kg of coal gangue, 15kg of desulfurized gypsum powder, 10kg of calcium stearate, 10kg of coconut shell charcoal and Auxiliary 4kg.

[0027] Among them, the above-mentioned additives include 35% water-reducing agent, 35% water-repellent agent and 30% foaming agent by weight percentage. It is composed of 65% sodium lauryl sulfate and 35% fatty alcohol polyoxyethylene ether sodium sulfate in weight percentage.

[0028] And in the specific implementation, the waste mine tailings, coal gangue and coconut shell charcoal of the above-mentioned raw materials are crushed to a particle size of 1-2mm by a hammer crusher.

[0029] 2. Preparation method

[0030] The preparation method of the above-mentioned wear-resistant and permeable square brick is carried out acco...

Embodiment 2

[0037] 1. Selection of raw materials

[0038] A wear-resistant and permeable square brick, including the following raw materials: 100kg of composite Portland cement, 50kg of attapulgite clay, 35kg of waste mine tailings, 25kg of coal gangue, 20kg of desulfurized gypsum powder, 15kg of calcium stearate, 15kg of coconut shell charcoal, Auxiliary 5kg.

[0039] Among them, the above-mentioned additives include 35% of water-reducing agent, 35% of water-repellent agent and 30% of foaming agent by weight percentage. The water-reducing agent is a mixture of calcium lignosulfonate and sodium polyacrylate, and the mass ratio of the two is The ratio is 2:1, the water-repellent agent adopts silicone emulsion, and the foaming agent is composed of 65% sodium lauryl sulfate and 35% sodium fatty alcohol polyoxyethylene ether sulfate by weight percentage.

[0040] And in the specific implementation, the waste mine tailings, coal gangue and coconut shell charcoal of the above-mentioned raw mat...

Embodiment 3

[0049] 1. Selection of raw materials

[0050] A wear-resistant and permeable square brick, including the following raw materials: 120kg of composite Portland cement, 60kg of attapulgite clay, 40kg of waste mine tailings, 30kg of coal gangue, 25kg of desulfurized gypsum powder, 20kg of calcium stearate, 20kg of coconut shell charcoal, Auxiliary 6kg.

[0051] Among them, the above-mentioned additives include 35% of water-reducing agent, 35% of water-repellent agent and 30% of foaming agent by weight percentage. The percentage meter is composed of 65% sodium lauryl sulfate and 35% sodium fatty alcohol polyoxyethylene ether sulfate.

[0052] And in the specific implementation, the waste mine tailings, coal gangue and coconut shell charcoal of the above-mentioned raw materials are crushed to a particle size of 1-2mm by a hammer crusher.

[0053] 2. Preparation method

[0054] The preparation method of the above-mentioned wear-resistant and permeable square brick is carried out acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com