Deoiling agent for oily sewage and preparation method thereof

A technology for degreasing agent and sewage, which is applied in water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc. It can solve the problems of single component of degreasing agent, complex preparation process, poor salt resistance, etc. , to achieve the effect of meeting environmental protection, simple synthesis process, and strong temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: Degreaser U 1 and its preparation method

[0029] (1) Degreaser U 1 The composition, components and molecular formula are as follows:

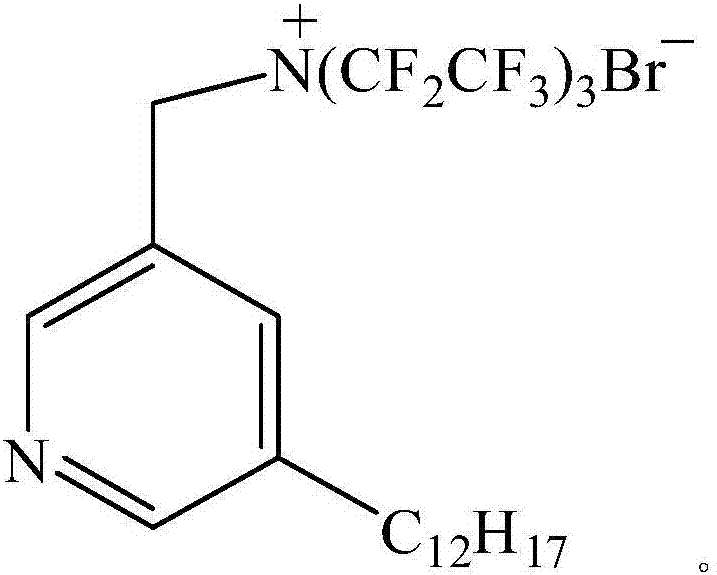

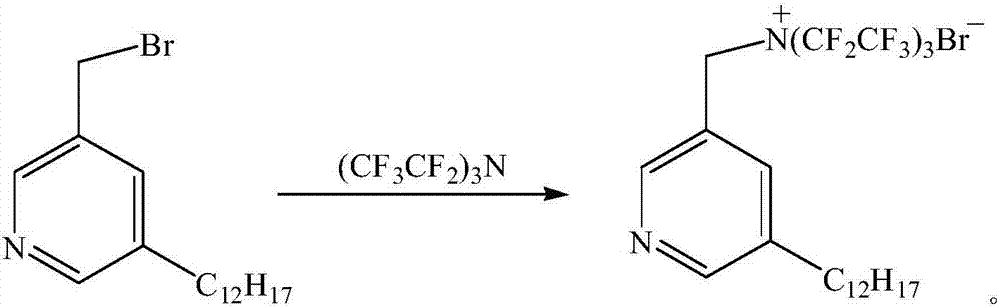

[0030] Degreaser U 1 Cationic degreasing agent is produced by reacting perfluorotriethylamine with 3-methyl bromide-5-dodecylpyridine in ethanol solution, and its molecular formula is as follows:

[0031]

[0032] The molar ratio of perfluorotriethylamine to 3-methyl bromide-5-dodecylpyridine is 1:0.8.

[0033] (2) Degreaser U 1 The preparation method is as follows:

[0034] ①Add 1 mol of perfluorotriethylamine to 3710g of ethanol, stir at 45°C, the stirring rate is 250rpm, and the stirring time is 30min, then slowly add 2.60g of catalyst potassium carbonate dropwise, after the addition of the catalyst is completed, cool down naturally to room temperature to obtain solution A;

[0035] ②Add 0.8mol of 3-methyl bromide-5-dodecylpyridine into solution A, slowly raise the temperature to 80°C, stir at 460rpm, react fo...

Embodiment 2

[0039] Embodiment 2: Degreaser U 2 and its preparation method

[0040] (1) Degreaser U 2 The composition, components and molecular formula are as follows:

[0041] Degreaser U 2 Cationic degreasing agent is produced by reacting perfluorotriethylamine with 3-methyl bromide-5-dodecylpyridine in ethanol solution, and its molecular formula is as follows:

[0042]

[0043] The molar ratio of perfluorotriethylamine to 3-methyl bromide-5-dodecylpyridine is 1:1.0.

[0044] (2) Degreaser U 2 The preparation method is as follows:

[0045] ① Add 1 mol of perfluorotriethylamine to 5100g of ethanol, stir at 50°C, the stirring rate is 300rpm, and the stirring time is 33min, then slowly add 3.12g of catalyst potassium carbonate dropwise, after the addition of the catalyst is completed, cool down naturally to room temperature to obtain solution A;

[0046] ②Add 1.0mol of 3-methylbromo-5-dodecylpyridine to solution A, slowly raise the temperature to 85°C, stir at 480rpm, react for 11...

Embodiment 3

[0050] Embodiment 3: Degreaser U 3 and its preparation method

[0051] (1) Degreaser U 3 The composition, components and molecular formula are as follows:

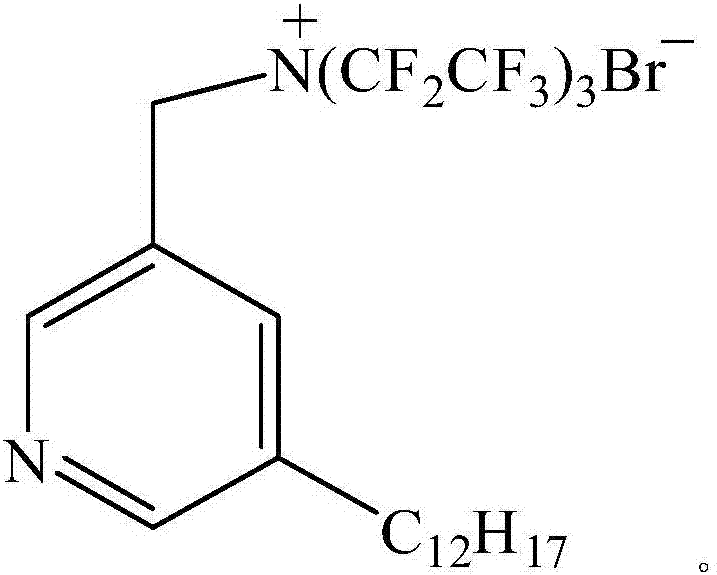

[0052] Degreaser U 3 Cationic degreasing agent is produced by reacting perfluorotriethylamine with 3-methyl bromide-5-dodecylpyridine in ethanol solution, and its molecular formula is as follows:

[0053]

[0054] The molar ratio of perfluorotriethylamine to 3-methyl bromide-5-dodecylpyridine is 1:1.2.

[0055] (2) Degreaser U 3 The preparation method is as follows:

[0056] ①Add 1 mol of perfluorotriethylamine to 6530g of ethanol, stir at 55°C, the stirring rate is 350rpm, and the stirring time is 37min, then slowly add 3.95g of catalyst potassium carbonate dropwise, after the catalyst is added, cool down naturally to room temperature to obtain solution A;

[0057] ②Add 1.2 mol of 3-methylbromo-5-dodecylpyridine into solution A, slowly raise the temperature to 82°C, stir at 450rpm, react for 10h, then cool down to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com