A kind of thermal insulation and damping coating for building and preparation method thereof

A technology for damping coatings and constructions, applied in the direction of reflection/signal coatings, coatings, etc., can solve problems such as poor heat insulation effect, and achieve the effect of improving heat insulation functionality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

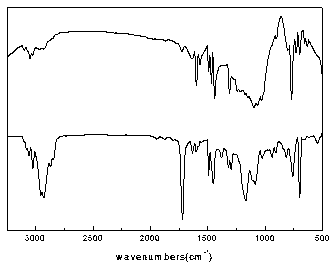

Image

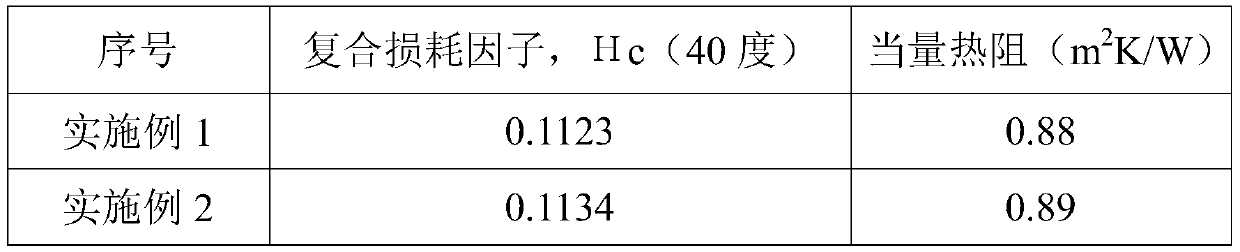

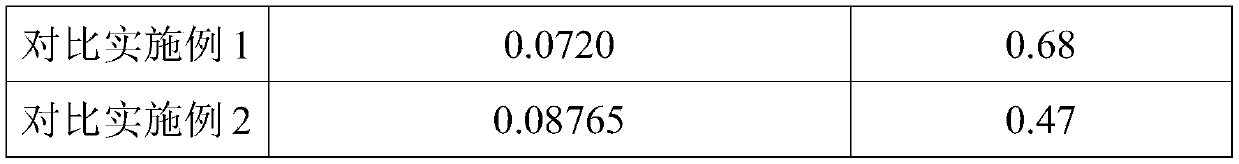

Examples

Embodiment 1

[0028] (1) Add 15g of titanium silicate with a particle size of 10 microns, 6g of sericite with a particle size of 15 microns, 9g of silicon carbide with a particle size of 20 microns, 1g of dispersant, 1g of defoamer and 1g of preservative into a beaker and stir at high speed well mixed.

[0029] (2) Add 40g of silicon-acrylic emulsion, 1g of film-forming aid and 20g of porous cross-linked polystyrene microspheres with a particle size of 5 microns. After 16g of distilled water is stirred and mixed at a high speed, use 15% sodium carbonate aqueous solution to adjust the pH value to 8. Stir again evenly to obtain a heat-insulating and damping coating for buildings.

Embodiment 2

[0031] (1) Add 15g of titanium silicate with a particle size of 10 microns, 6g of sericite with a particle size of 15 microns, 9g of silicon carbide with a particle size of 20 microns, 1g of dispersant, 1g of defoamer and 1g of preservative into a beaker and stir at high speed well mixed.

[0032] (2) Add 40g of silicon-acrylic emulsion, 1g of film-forming aid and 20g of porous cross-linked styrene and methyl methacrylate copolymer microspheres with a particle size of 5 microns. After 16g of distilled water is stirred and mixed evenly at a high speed, use 15% The sodium carbonate aqueous solution is adjusted to a pH value of 8, and then stirred evenly to obtain a heat-insulating and damping coating for construction.

Embodiment 3

[0034] (1) Add 20g of titanium silicate with a particle size of 10 microns, 9g of sericite with a particle size of 15 microns, 11g of silicon carbide with a particle size of 20 microns, 1g of dispersant, 1g of defoamer and 1g of preservative into a beaker and stir at high speed well mixed.

[0035] (2) Add 35g of silicon-acrylic emulsion, 1g of film-forming aid and 20g of porous cross-linked styrene and methyl methacrylate copolymer microspheres with a particle size of 5 microns. After 16g of distilled water is stirred and mixed evenly at a high speed, use 15% The sodium carbonate aqueous solution is adjusted to a pH value of 8, and then stirred evenly to obtain a heat-insulating and damping coating for construction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com