Preparation method for tungsten disulfide sheet-shaped nanomaterial

A tungsten disulfide flake, nanomaterial technology, used in the manufacture of hybrid/electric double-layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of limited mass production, and achieve the effect of increasing performance, excellent performance and high crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

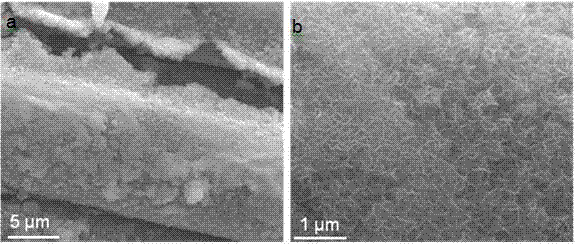

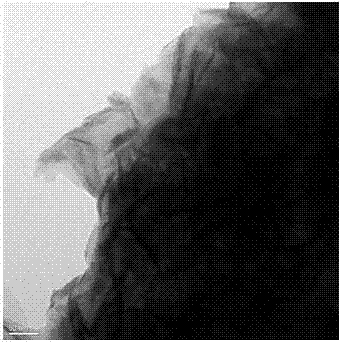

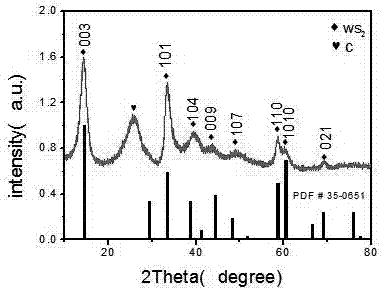

Image

Examples

Embodiment 1

[0028] WS 2 The synthesis of is realized in one step by hydrothermal method, concrete steps:

[0029] (1) Weigh 0.5635g of thioacetamide in a beaker, add 20ml of water, stir to dissolve, set aside.

[0030] (2) Weigh 0.5950g of tungsten hexachloride solid and add it to the solution of (1) above, continue to stir for one hour, put it into a 25ml high-temperature reaction kettle, add clean (2cm×3cm) commercial carbon cloth, and put it in the oven Reacted in medium for 12h, the reaction temperature was 250°C, and it was taken out.

[0031] Among them, the commercial carbon cloth is pretreated first, and the pretreatment operation is:

[0032] Ultrasonic cleaning with ethanol for 15 minutes, then dissolving 0.759g of sodium tungstate in 12ml of 3M hydrochloric acid, adding 2ml of 30% hydrogen peroxide and stirring until clear as the seed solution. Soak the cleaned commercial carbon cloth in the above seed solution, and grow crystal nuclei on a heating plate at a temperature of ...

Embodiment 2-7

[0035] Based on the scheme of Example 1, by adjusting different reaction conditions, the WS 2 growth conditions are listed in Table 1.

[0036] WS in table 1. embodiment 1~7 2 Regulatory conditions for the growth of flakes

[0037]

[0038] Other preparation conditions in comparative example 1 and 2 are with embodiment 1, and different conditions and results are as shown in table 2:

[0039] Table 2

[0040]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com