Inorganic perovskite light-absorbing material and preparation method thereof

A light-absorbing material, inorganic calcium technology, applied in photovoltaic power generation, final product manufacturing, sustainable manufacturing/processing, etc., can solve problems such as difficult to prepare high-quality thin films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

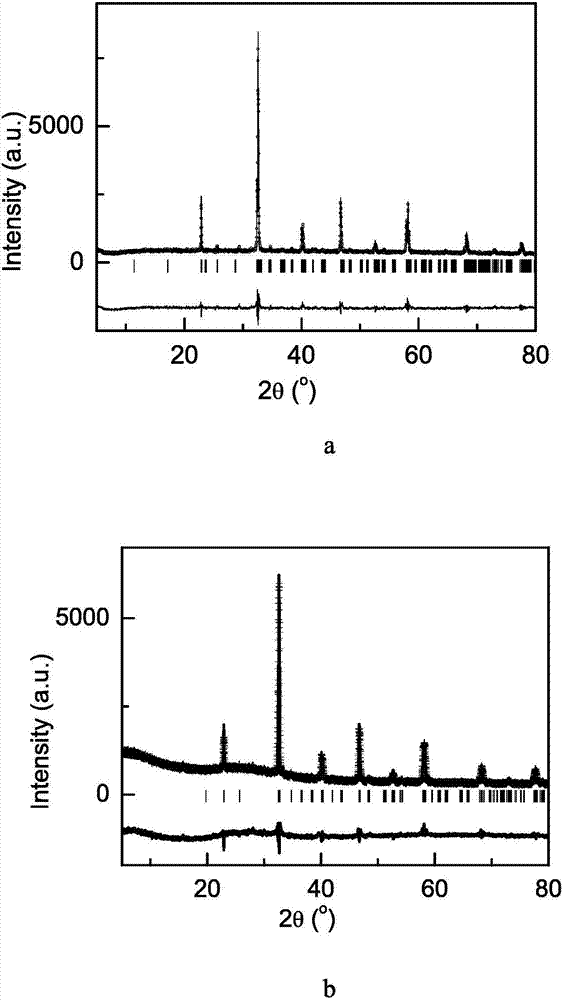

Embodiment 1

[0039](1) With the nitrate of the raw material, La(NO 3 ) 3 , a ratio of Y(NO 3 ) 3 , b proportion of Dy(NO 3 ) 3 , d proportion of Er(NO 3 ) 3 , 0.5 ratio of Co(NO 3 ) 2 and 0.5 ratio of Mn(NO 3 ) 3 respectively dissolved in water, c / 2 ratio of Bi 2 o 3 Dissolve in nitric acid, stir well, prepare (La 1-a-b-c-d Y a Dy b Bi c Er d )Co 0.5 mn 0.5 o 3 The precursor solution;

[0040] (2) In the solution, add citric acid in a ratio of 1:1.5 of the mass ratio of nitrate raw material and citric acid in (1), and stir with a magnetic stirrer for 30 minutes;

[0041] (3) In (2) sol, add ethylene glycol with the volume ratio of solution and ethylene glycol 1: 0.8 ratio, make sol-gel, stir with magnetic stirrer for 30 minutes;

[0042] (4) Spin-coating on an In-doped ZnO substrate;

[0043] (5) drying the nitrate spin-coated film of (4) deposited on an In-doped ZnO substrate in an oven at 100° C. for 24 hours;

[0044] (6) heat-treat the dried (5) in a box furnace ...

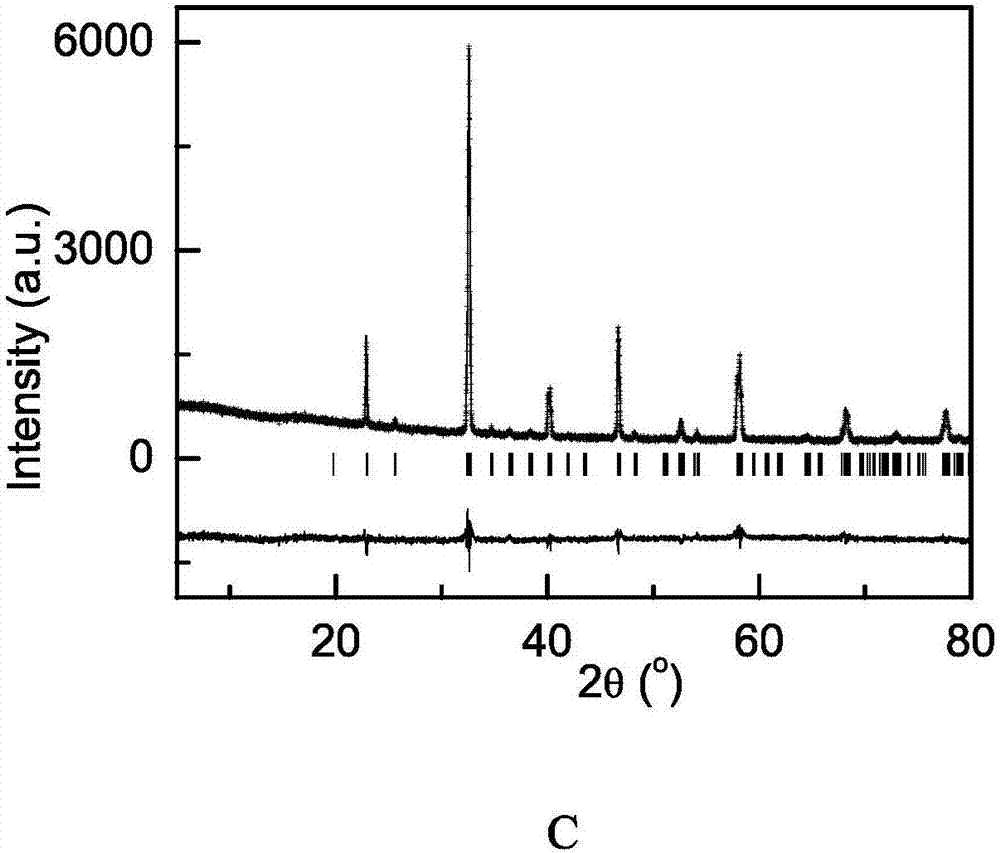

Embodiment 2

[0052] (1) With the nitrate of the raw material, La(NO 3 ) 3 , a ratio of Y(NO 3 ) 3 , b proportion of Dy(NO 3 ) 3 , d proportion of Er(NO 3 ) 3 , 0.5 ratio of Ni(NO 3 ) 2 and 0.5 ratio of Mn(NO 3 ) 3 respectively dissolved in water, c / 2 ratio of Bi 2 o 3 Dissolve in nitric acid, stir well, prepare (La 1-a-b-c-d Y a Dy b Bi c Er d ) Ni 0.5 mn 0.5 o 3 The precursor solution;

[0053] (2) In the solution, add citric acid in a ratio of 1:1.5 of the mass ratio of nitrate raw material and citric acid in (1), and stir with a magnetic stirrer for 30 minutes;

[0054] (3) In (2) sol, add ethylene glycol with the volume ratio of solution and ethylene glycol 1: 0.8 ratio, make sol-gel, stir with magnetic stirrer for 30 minutes;

[0055] (4) Spin-coating on an In-doped ZnO substrate;

[0056] (5) drying the nitrate spin-coated film of (4) deposited on an In-doped ZnO substrate in an oven at 100° C. for 24 hours;

[0057] (6) heat-treat the dried (5) in a box furnac...

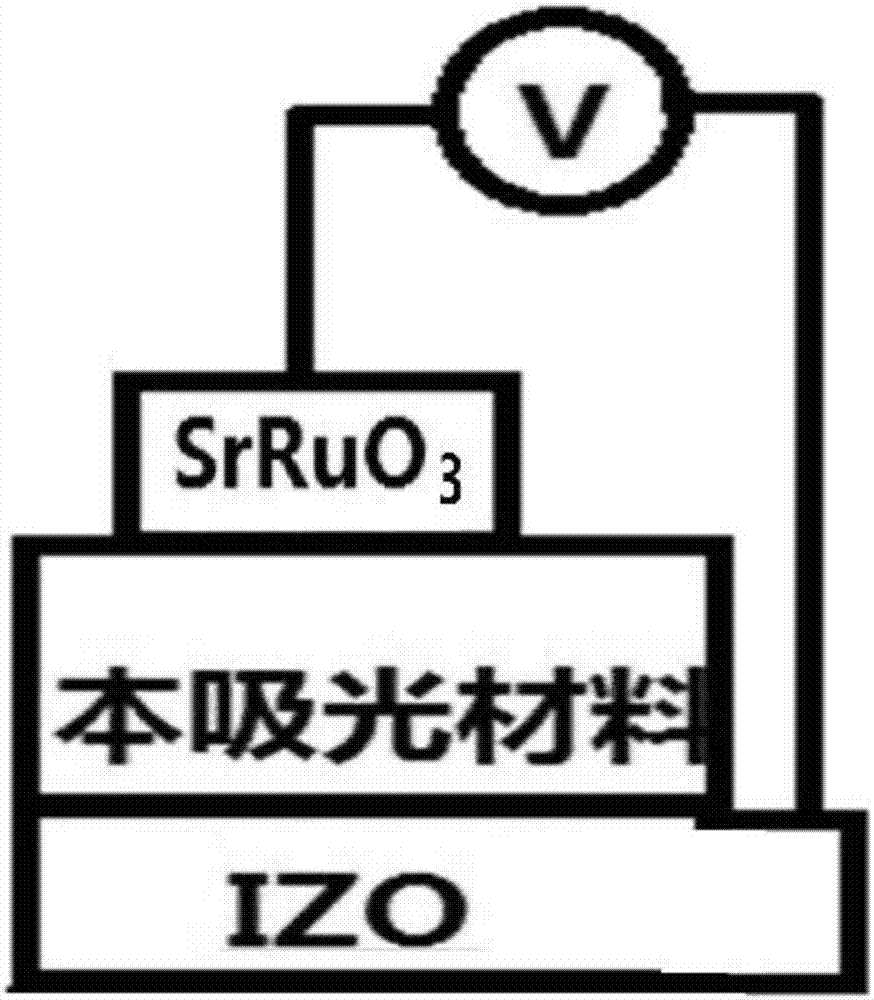

Embodiment 3

[0064] (1) With the nitrate of the raw material, La(NO 3 ) 3 , a ratio of Y(NO 3 ) 3 , b proportion of Dy(NO 3 ) 3 , d proportion of Er(NO 3 ) 3 , 0.5 ratio of Cr(NO 3 ) 2 and 0.5 ratio of Mn(NO 3 ) 3 respectively dissolved in water, c / 2 ratio of Bi 2 o 3 Dissolve in nitric acid, stir well, prepare (La 1-a-b-c-d Y a Dy b Bi c Er d )Cr 0.5 mn 0.5 o 3 The precursor solution;

[0065] (2) In the solution, add citric acid in a ratio of 1:1.5 of the mass ratio of nitrate raw material and citric acid in (1), and stir with a magnetic stirrer for 30 minutes;

[0066] (3) In (2) sol, add ethylene glycol with the volume ratio of solution and ethylene glycol 1: 0.8 ratio, make sol-gel, stir with magnetic stirrer for 30 minutes;

[0067] (4) Spin-coating on an In-doped ZnO substrate;

[0068] (5) drying the nitrate spin-coated film of (4) deposited on an In-doped ZnO substrate in an oven at 100° C. for 24 hours;

[0069] (6) heat-treat the dried (5) in a box furnace...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Band gap width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com