Preparation method of CdS/GO composite material with three-dimensional flowerlike nanostructure

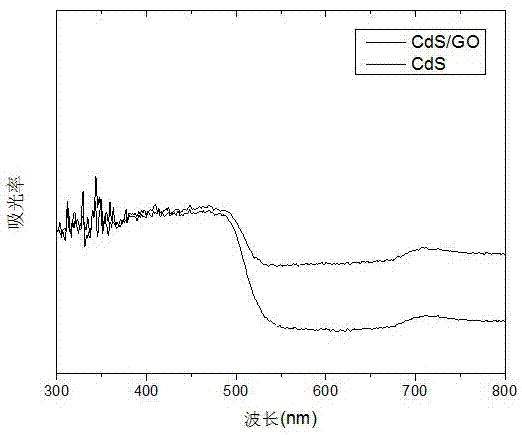

A three-dimensional flower-like, uniform technology, applied in the field of photocatalysis and composite materials, can solve the problems of CdS photocorrosion, etc., and achieve the effect of improving photocatalytic stability, improving photocatalytic activity, and excellent photocatalytic degradation characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Preparation of graphite oxide: Disperse 1.5g of 325 mesh flake graphite, 3g of potassium persulfate and 3g of phosphorus pentoxide into 10mL of concentrated sulfuric acid solution, react at 80~90°C for 24 h, filter the product, wash and dry to obtain pre-oxidized graphite. Disperse 1g of the pre-oxidized graphite synthesized above in the mixed acid formed by 5mL of concentrated sulfuric acid and 15mL of concentrated nitric acid, control the temperature at 0~5°C, add 4g of potassium permanganate under stirring, then raise the temperature to 50~60°C and continue stirring for 10~ After 12 hours, brown-green graphite oxide was obtained; then 5 mL of hydrogen peroxide was added under stirring in an ice bath, and after the solution turned golden yellow, it was washed with hydrochloric acid, washed repeatedly with ethanol and water, centrifuged, and dried to obtain graphite oxide.

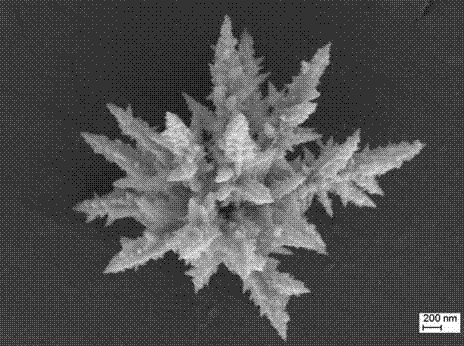

[0026] Preparation of three-dimensional flower-like CdS: Add 1mmoL cadmium acetate and 3mmoL th...

Embodiment 2

[0029] The preparation of graphite oxide: with embodiment 1.

[0030] Preparation of three-dimensional flower-like CdS: Add 1mmoL cadmium acetate and 3mmoL thiourea into 50mL deionized water and stir to dissolve them. During this process, slowly add 20mL of pre-configured 10mmoL / L L-aspartic acid solution and continue stirring After 30 min, the homogeneous solution was transferred to a 100 mL reactor and reacted at 180 °C for 4 h. The precipitate was centrifuged, washed with ethanol and distilled water several times, and the product was dried in a 60 °C drying oven for 12 h to obtain three-dimensional flower-like CdS. The removal rate of flower-like CdS for MB was 81.97%.

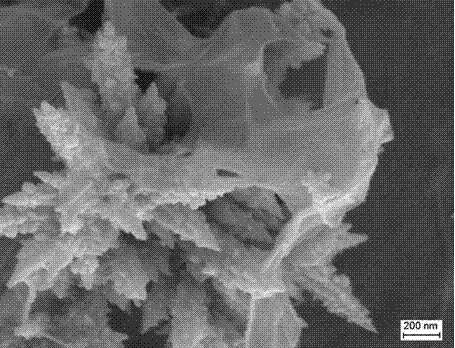

[0031] Preparation of CdS / GO composite material: Firstly, 0.5mg of dry graphite oxide was firstly ultrasonicated in 5ml of deionized water for 6h to obtain a transparent bright yellow solution; then 50mg of flower-shaped CdS with the best catalytic effect for degradation was weighed and added to it, and the...

Embodiment 3

[0033] The preparation of graphite oxide: with embodiment 1.

[0034]Preparation of three-dimensional flower-like CdS: Add 1mmoL cadmium acetate and 3mmoL thiourea into 50mL deionized water and stir to dissolve them. During this process, slowly add 20mL of pre-configured 15mmoL / L L-aspartic acid solution and continue stirring After 30 min, the homogeneous solution was transferred to a 100 mL reactor and reacted at 180 °C for 4 h. The precipitate was centrifuged, washed with ethanol and distilled water several times, and the product was dried in a 60 °C drying oven for 12 h to obtain three-dimensional flower-like CdS. The removal rate of flower-like CdS for MB was 78.8%.

[0035] Preparation of CdS / GO composite material: 2.5mg of dry graphite oxide was firstly ultrasonicated in 5ml of deionized water for 6h to obtain a transparent bright yellow solution; then 50mg of flower-like CdS with the best catalytic effect degradation was weighed and added to it, and then 40mL was added ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com