Preparation method of surface-modified g-C3N4

A surface modification, g-c3n4 technology, applied in the field of materials and catalysis science, can solve the problems of narrow absorption range, small specific surface area and low catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

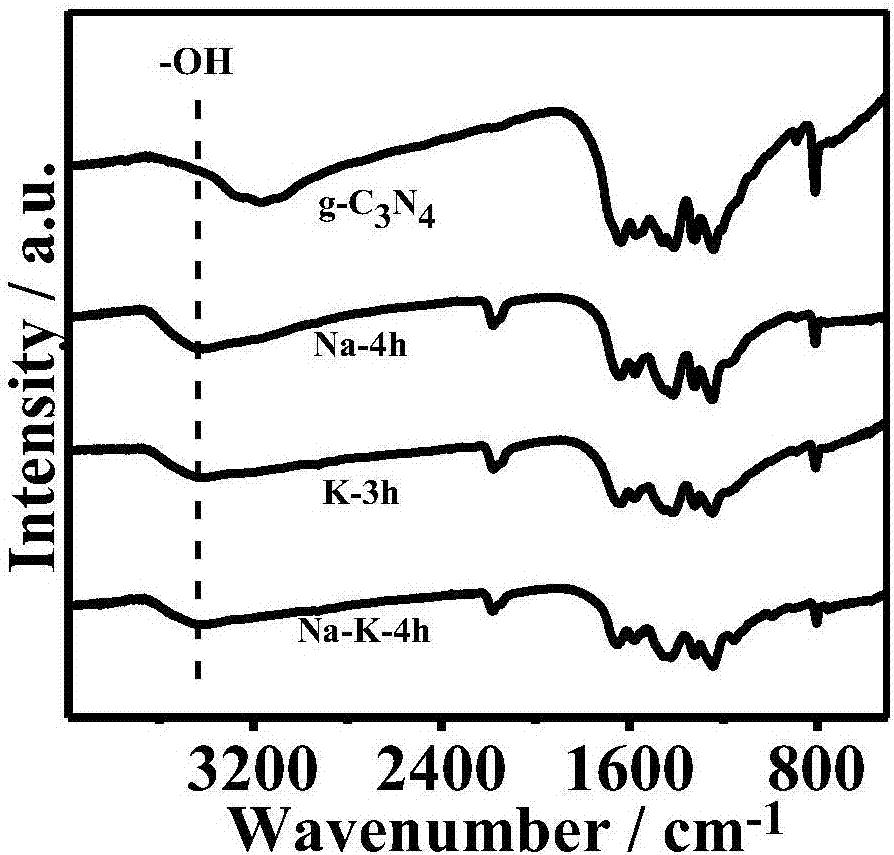

[0023] Weigh 600mg of g-C 3 N 4 and 1200mg of sodium chloride, mixed and ground evenly, and then in N 2 Calcined at 550°C for 4 hours under protection, then centrifuged and washed with water to obtain modified g-C 3 N 4 (referred to as Na-4h).

Embodiment 2

[0025] Weigh 600mg of g-C 3 N 4 and 1200mg potassium chloride, the mixture is ground evenly, and then in N 2 Calcined at 550°C for 3 hours under protection, then centrifuged and washed with water to obtain modified g-C 3 N 4 (referred to as K-3h).

Embodiment 3

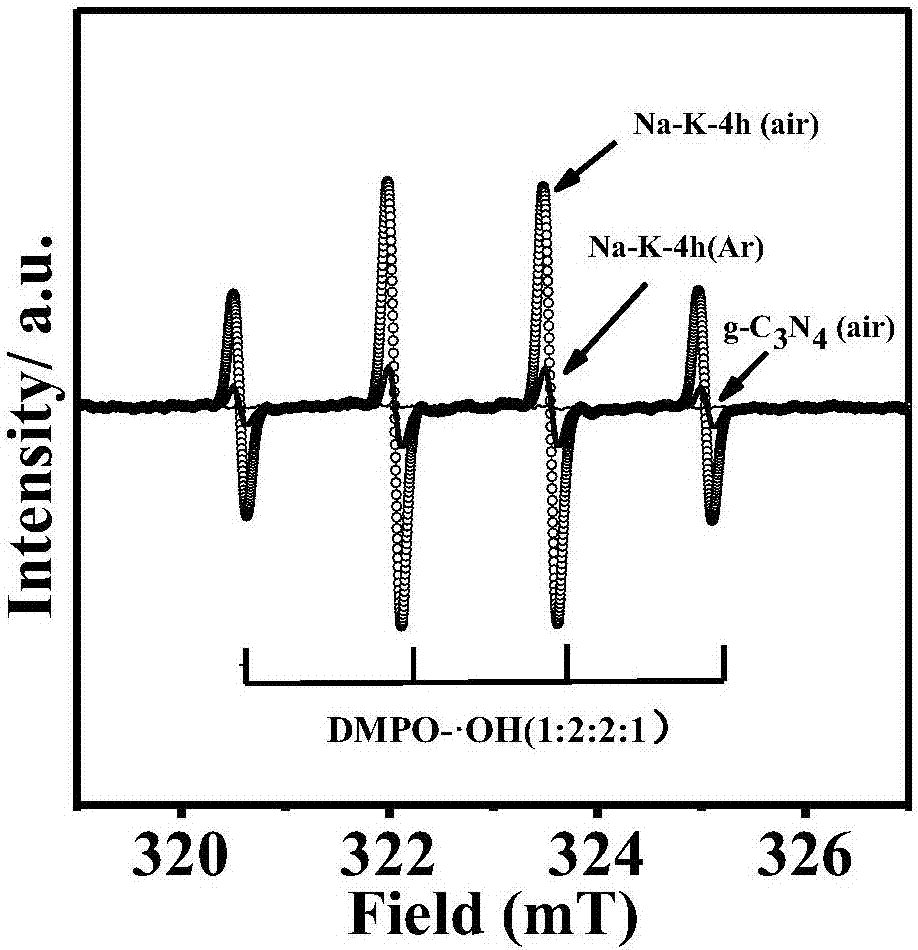

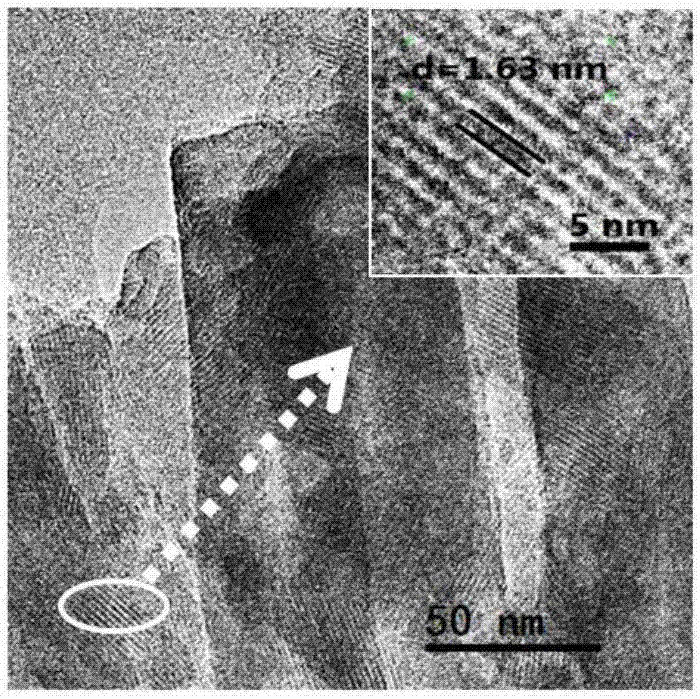

[0027] Weigh 600mg g-C 3 N 4 , 600mg sodium chloride and 600mg potassium chloride, mixed and ground evenly, then in N 2 Calcined at 550°C for 4 hours under protective conditions, then centrifuged and washed with water to obtain modified g-C 3 N 4(referred to as Na-K-4h).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com