Dealcoholized silicone rubber sealant

A sealant, dimethyl silicone oil technology, used in adhesives, adhesive additives, polymer adhesive additives, etc., can solve the problems of unresearched initial curing speed and initial shear strength, and achieve excellent adhesion and The effect of curing speed, improving curing speed, good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

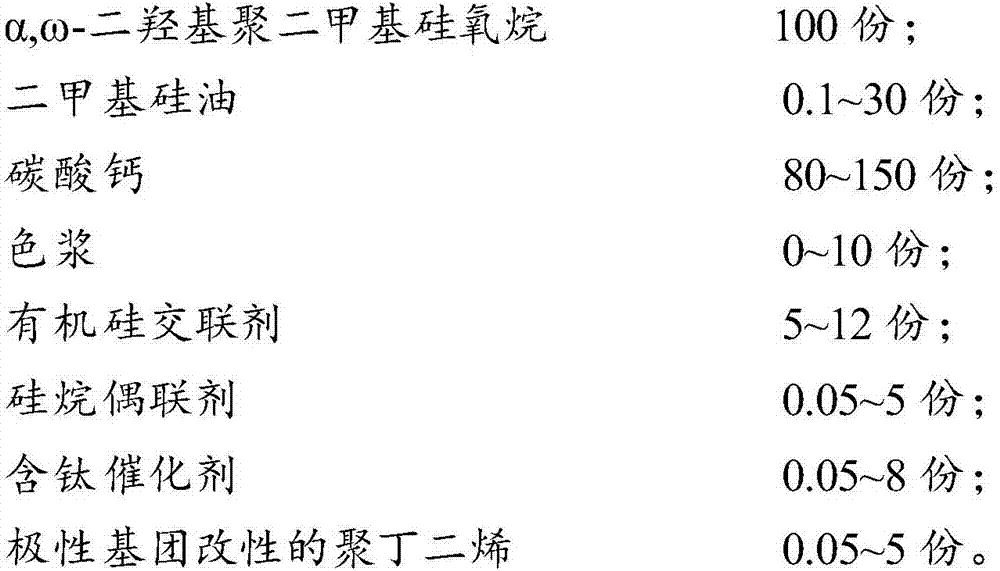

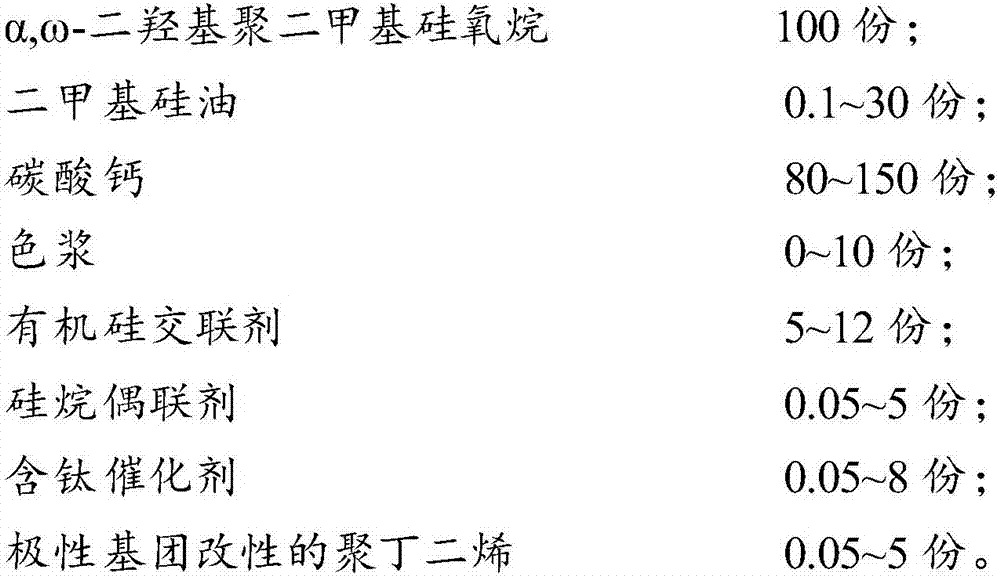

[0033] The present invention has no special limitation on the preparation method of the sealant, and it can be prepared by adopting the preparation method of the sealant well known to those skilled in the art. In the present invention, the preparation method of the sealant is preferably:

[0034] After mixing α,ω-dihydroxy polydimethylsiloxane, dimethyl silicone oil, calcium carbonate and the color paste, vacuum dehydration after heating, and cooling to obtain a mixture;

[0035] mixing the mixture with an organosilicon crosslinking agent and a titanium-containing catalyst, and stirring under vacuum conditions to obtain a mixture;

[0036] Adding silane coupling agent and polar group-modified polybutadiene into the mixture, stirring and lowering the temperature under vacuum condition, to obtain the sealant.

[0037]In the present invention, the heating temperature is preferably 100-150°C, more preferably 120-130°C. In the present invention, the pressure of the vacuum dehydra...

Embodiment 1

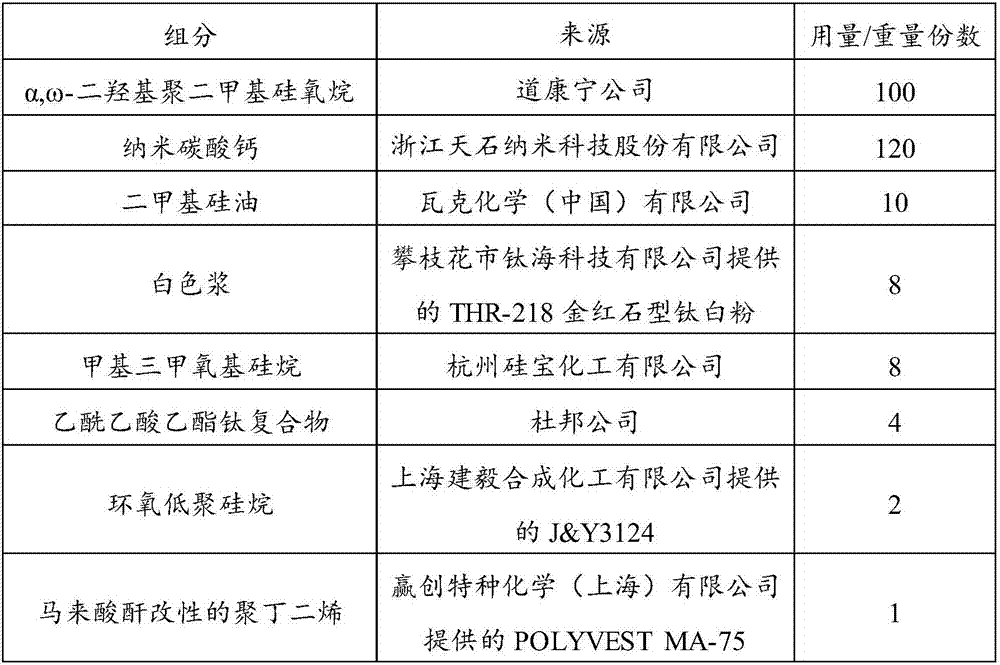

[0040] Set the kinematic viscosity to 20000mm 2 / s of α, ω-dihydroxy polydimethylsiloxane, 350mm 2 / s simethicone oil, nano-calcium carbonate, and white slurry are put into a high-speed dispersing planetary machine and stirred, and heated to 120°C at the same time, vacuum dehydrated at -0.09~-0.1MPa for 3 hours, and cooled to below 50°C after the moisture is removed , add methyltrimethoxysilane, ethyl acetoacetate titanium compound, stir evenly under vacuum condition, then add epoxy oligosilane and maleic anhydride modified polybutadiene, stir evenly under vacuum condition The amount and source of the above raw materials are shown in Table 1, and Table 1 shows the amount and source of the raw materials used in Example 1 of the present invention.

[0041] Table 1 The amount and source of raw materials used in Embodiment 1 of the present invention

[0042]

Embodiment 2

[0044] Set the kinematic viscosity to 20000mm 2 / s of α, ω-dihydroxy polydimethylsiloxane, 350mm 2 Put the simethicone oil, nano-calcium carbonate, and black slurry into the high-speed dispersing planetary machine and stir at the same time, heat to 120°C at the same time, vacuum dehydrate at -0.09~-0.1MPa for 3 hours, and cool down to below 50°C after the water is removed , add methyltrimethoxysilane, vinyltrimethoxysilane and ethyl acetoacetate titanium complex, stir evenly under vacuum, then add epoxy oligosilane and maleic anhydride modified polybutadiene, Stir evenly under vacuum conditions and then discharge to obtain a silicone rubber sealant. The contents and sources of the above raw materials are shown in Table 2, and Table 2 shows the amount and source of raw materials used in Example 2 of the present invention.

[0045] Table 2 The used raw material consumption and source of the embodiment of the present invention 2

[0046]

[0047]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com