Preparation method for high-concentration nanometer red-phosphorus photocatalyst dispersion

A technology of photocatalysts and dispersions, applied in chemical instruments and methods, physical/chemical process catalysts, inorganic chemistry, etc., can solve the problems of unfavorable surface catalytic reactions, difficulty in obtaining nanoparticles, small specific surface area, etc., and achieve specific surface area High, simple method, fast separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of the high-concentration nanometer red phosphorescent catalyst dispersion liquid of the present invention comprises the following steps:

[0029] Step 1: Grinding red phosphorus in water and sieving to obtain micron-sized red phosphorus particles;

[0030] Step 2: heat-treating the obtained micron-sized red phosphorus particles in a solvent at a temperature of 160-220°C for 3-72 hours;

[0031] The solvent is a mixed solution of water, ethylene glycol or glycerol and NaOH, wherein: the volume ratio of water to ethylene glycol or glycerol is 11:1 to 3:1, and the concentration of NaOH is 0.05 to 0.20mol / L;

[0032] Step 3: centrifuging, washing, drying, and annealing the heat-treated red phosphorus to obtain nano-scale red phosphorus;

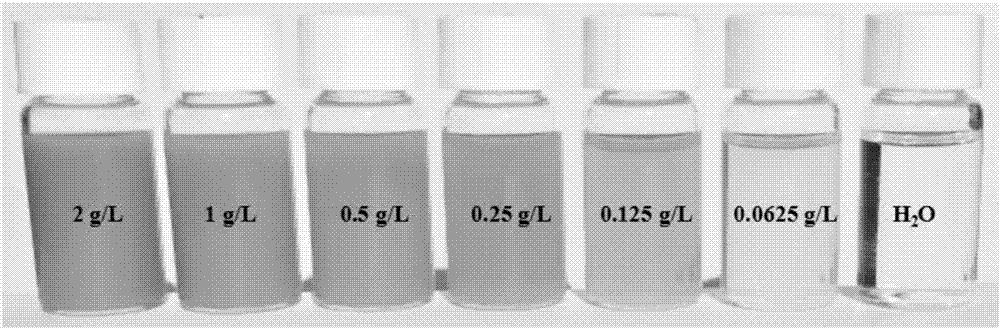

[0033] Step 4: Dispersing the obtained nano-scale red phosphorus in water and ultrasonically treating it to obtain a nano-red phosphorescent catalyst dispersion;

[0034] Wherein, in Step 3, the centrifugal spee...

Embodiment 1

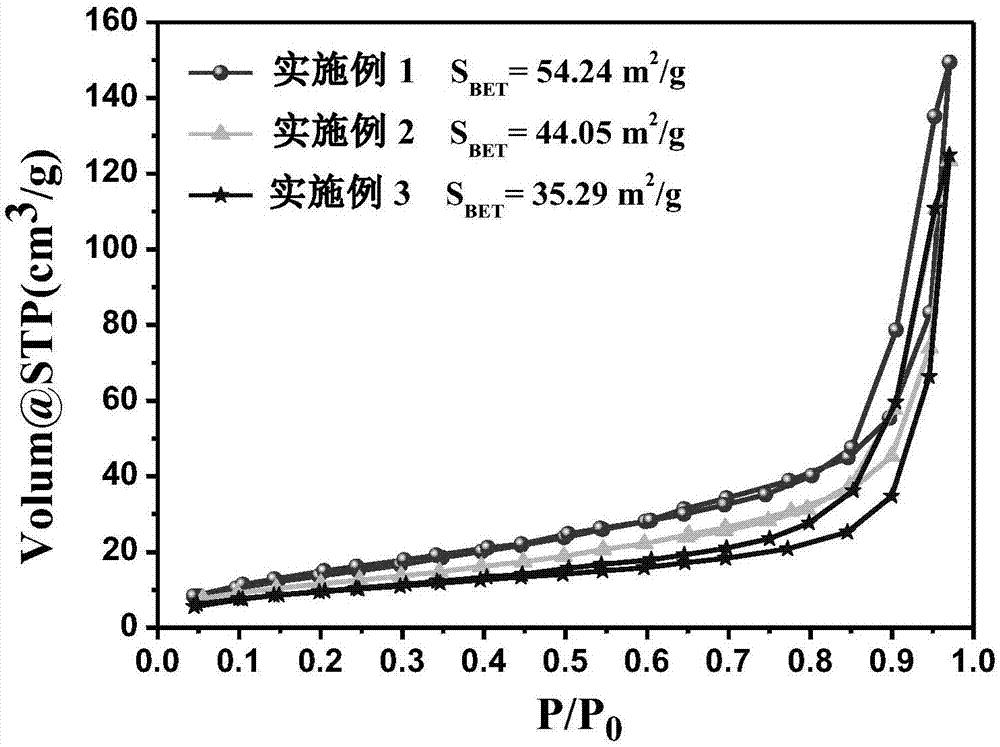

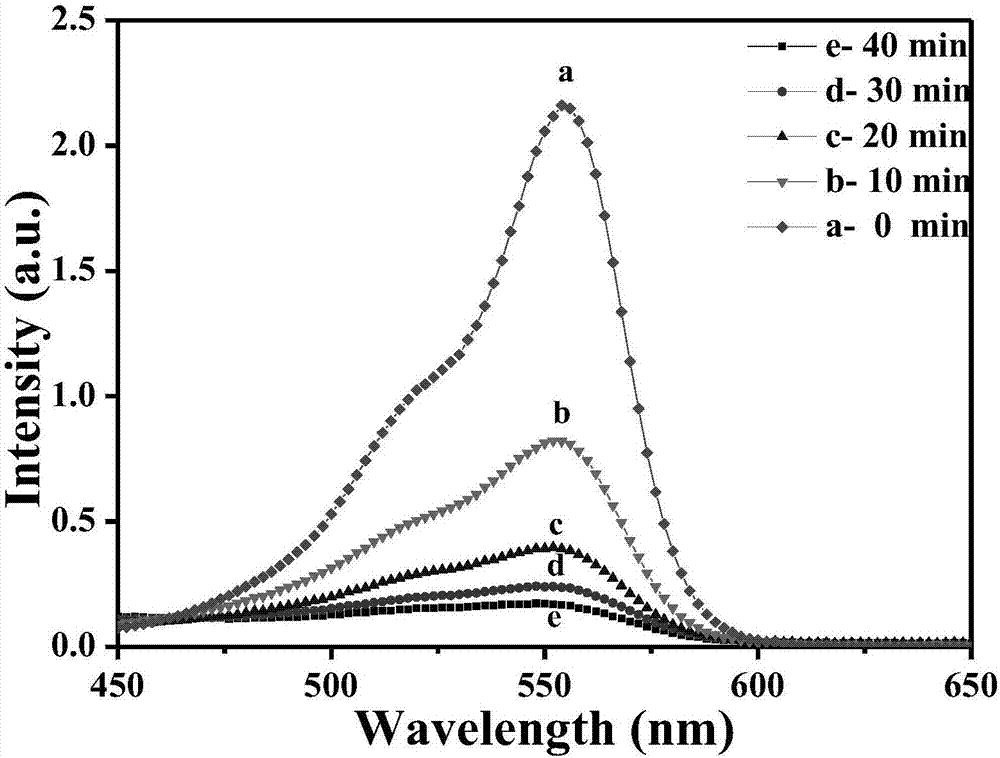

[0042] At room temperature, commercially available red phosphorus was ground in water, sieved with a 120-mesh sieve, and dried to obtain micron-sized red phosphorus particles. Weighed 3 g and dispersed it in a reaction mixture consisting of 55 mL of water, 5 mL of ethylene glycol, and 0.12 g of NaOH. solution, stirred for 30 minutes, transferred to a 100mL hydrothermal synthesis reaction tank with polytetrafluoroethylene lining, sealed and placed in a blast drying oven, heated at 5°C / min to 200°C for 24h, and cooled naturally after the reaction was completed To room temperature, the product was repeatedly washed with distilled water and absolute ethanol, centrifuged (12000rmp / min), dried at 80°C, annealed at 380°C for 1h under the protection of argon, and finally, 1.0g of the product was dispersed in 500mL In water, 300W, 20KHz ultrasound was used for 10h to obtain a high-concentration nanometer red phosphorescent catalyst dispersion. Take 6 mL of nano-red phosphorus dispersio...

Embodiment 2

[0044]At room temperature, commercially available red phosphorus was ground in water, sieved with a 120-mesh sieve, and dried to obtain micron-sized red phosphorus particles. Weighed 3 g and dispersed it in a reaction mixture consisting of 45 mL of water, 15 mL of ethylene glycol, and 0.48 g of NaOH. solution, stirred for 30 minutes, transferred to a 100mL hydrothermal synthesis reaction tank with polytetrafluoroethylene lining, sealed and placed in a blast drying oven, heated at 5°C / min to 160°C for 12h, and cooled naturally after the reaction was completed To room temperature, the product was repeatedly washed with distilled water and absolute ethanol, centrifuged (8000rmp / min), dried at 50°C, annealed at 350°C for 2h under the protection of argon, and finally, 1.0g of the product was dispersed in 500mL In water, use 800W, 20KHz ultrasound for 2h to obtain a high-concentration nanometer red phosphorescent catalyst dispersion. Take 6 mL of nano-red phosphorus dispersion and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com