A method for green synthesis of petroleum sulfonate for tertiary oil recovery in a high-gravity reactor

A technology of hypergravity reactor and petroleum sulfonate, which is applied in the fields of sulfonate preparation, chemical instruments and methods, drilling composition, etc., can solve the problem of long process flow, long material residence time, wide residence time distribution, etc. problems, to achieve the effect of shortening the process flow, reducing the cycle ratio, and reducing the size of the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0026] The specific embodiment (what oil is adopted respectively in the embodiment)

[0027] The invention is illustrated by the following non-limiting examples, but the invention is not limited to the following examples.

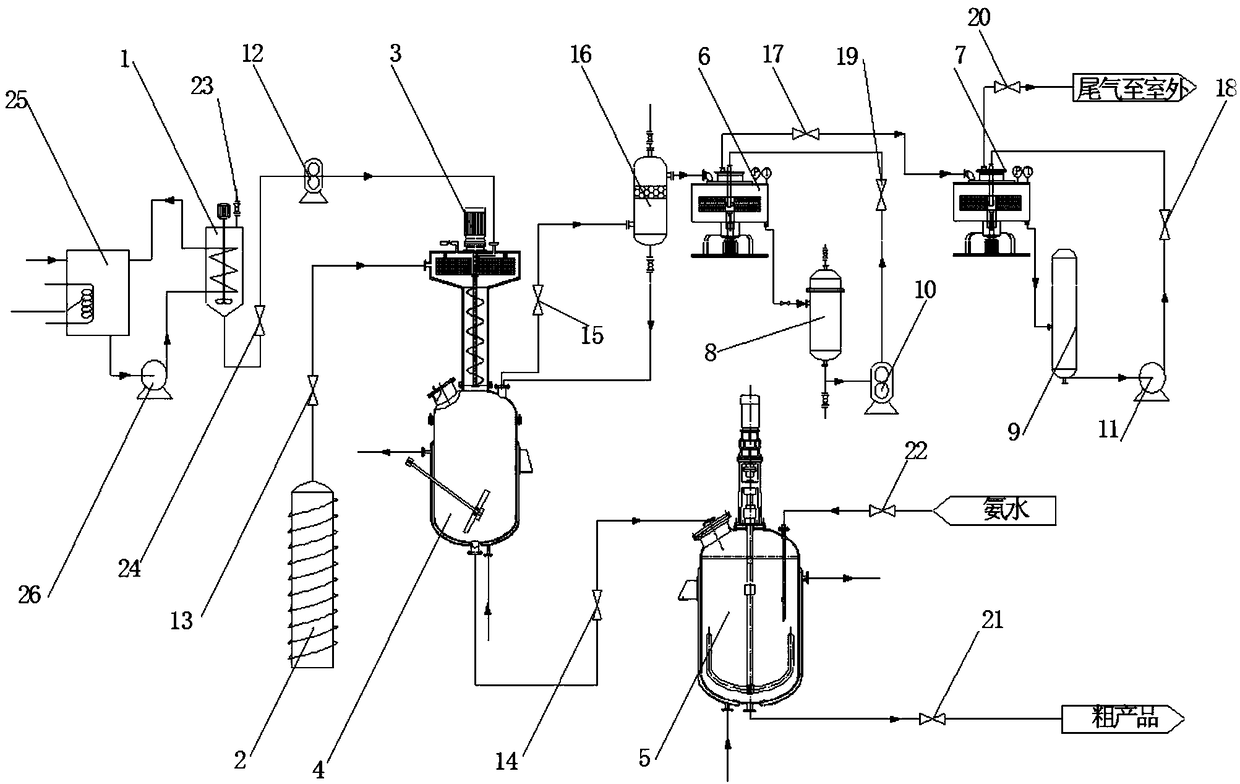

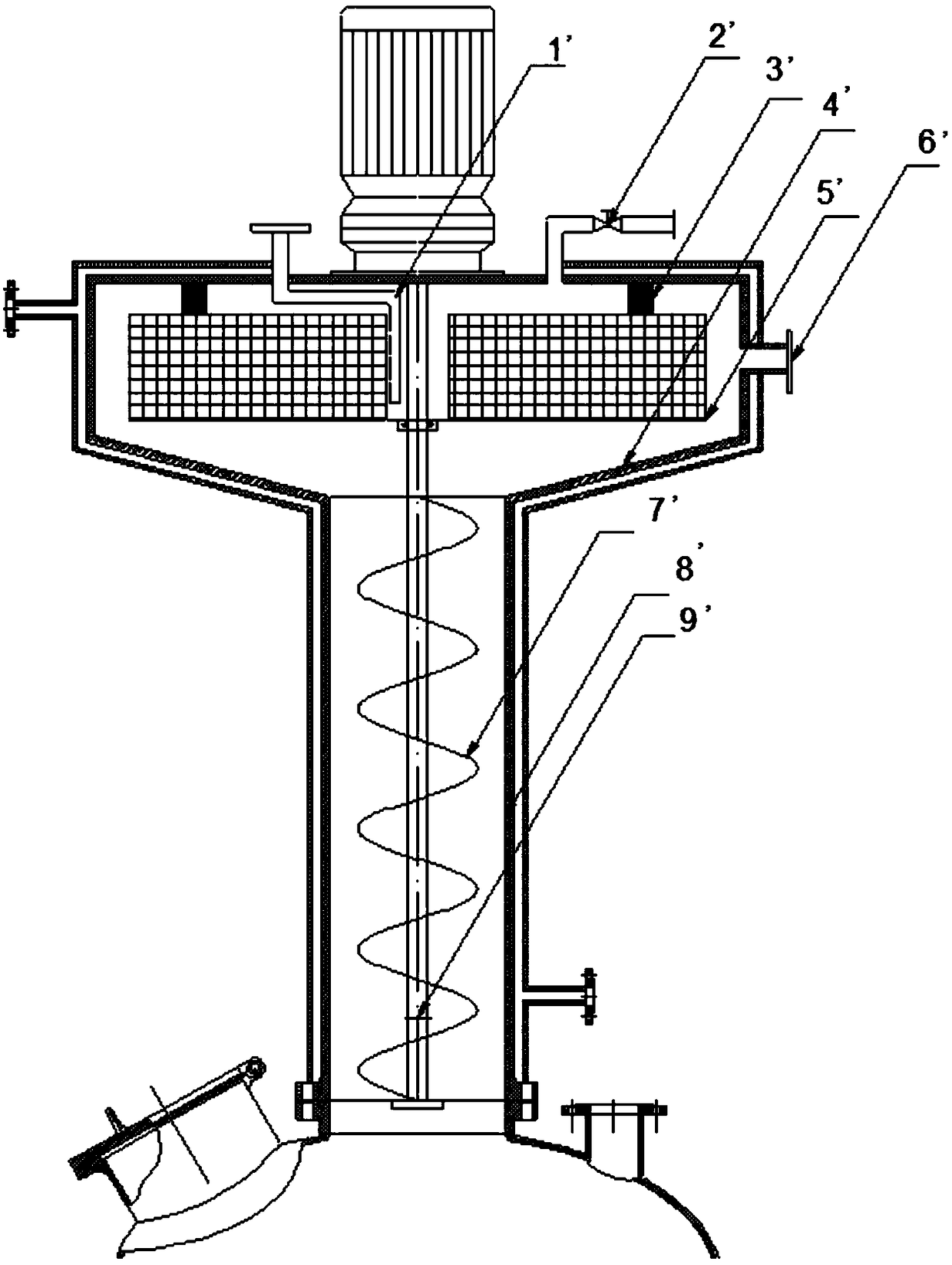

[0028] The following examples are carried out according to the process of the present invention and corresponding equipment. Sulfonating agent and petroleum distillate, where sulfonating agent refers to a certain concentration of SO 3 Gases, pre-prepared and stored in their respective storage tanks for future use. The starting materials for the sulfonation reaction pass through the gas valves according to the ratio and flow rate of the reaction materials recorded in the present invention, and the liquid pump is transported to the supergravity reactor 3. The reaction time is determined by the space velocity, and the reaction temperature is determined by the temperature of the reactor water jacket cooling medium. and traffic control. The sulfonation reacti...

Embodiment 1

[0031] The distillate oil is stored in the distillate oil storage tank, preheated by an electric heater to a reaction temperature of 20°C, and then pumped to the supergravity reactor by metering, SO 3 SO produced by conversion tower 3 Dilute to 5% with dried air, the airflow of sulfonating agent and distillate oil are both fed from the inner edge of the supergravity reactor rotor packing, and the distillate oil and SO4 are controlled by metering pump 12 and valve 13 3 The molar ratio is 1:1.05, the reaction time is 20min, the reaction temperature is 20°C, the aging time is 30min, and the aging temperature is 30°C. After the aging is completed, it enters the neutralization tank. pH value is 7~8; SO 3 Enter the first supergravity reactor 6 through the liquid remover, absorb with dilute sulfuric acid, and after pickling, SO 3 The removal rate is 45%, and the tail gas enters the second overweight reactor 7, absorbs with ammonia water, and SO 3 The removal rate is 97%.

[0032]...

Embodiment 2

[0034] The distillate oil is stored in the distillate oil storage tank, preheated by an electric heater to a reaction temperature of 30°C, and then pumped to the supergravity reactor by metering, SO 3 SO produced by conversion tower 3 Dilute to 8% with dried air. Both the sulfonating agent airflow and the distillate oil are fed from the inner edge of the supergravity reactor rotor packing, and the distillate oil and SO4 are controlled by metering pump 12 and valve 13. 3 The molar ratio is 1:1.05, the reaction time is 20min, the reaction temperature is 30°C, the aging time is 30min, and the aging temperature is 30°C. After the aging is completed, enter the neutralization tank. The neutralization temperature is consistent with the aging temperature. pH value is 7~8, SO 3 Enter the first supergravity reactor 6 through the liquid remover, absorb with dilute sulfuric acid, and after pickling, SO 3 The removal rate is 43.6%. The tail gas enters the second overweight reactor 7 and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| interfacial tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com