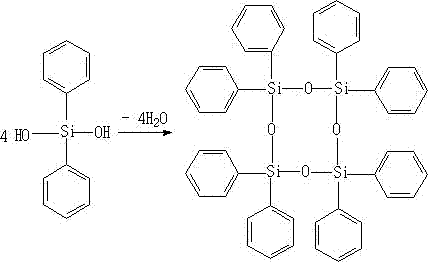

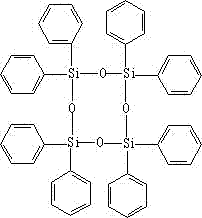

Preparation method for octaphenylcyclotetrasiloxane

A technology of octaphenylcyclotetrasiloxane and diphenylsilanediol, which is applied in the field of synthesizing organosilicon compounds, can solve problems such as difficult separation and recovery, pollution, and inability to recycle, and achieves mild temperature and high yield , Avoid the effect of the introduction of chloride ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Add 1000g of diphenylsilanediol with a mass percentage of 99.5% and 1000g of methanol into a 5L three-necked flask, stir until completely dissolved, add 0.02g of sodium hydroxide, heat the solution to 60°C, reflux for 4h; cool to room temperature, Stand still for 5 hours to fully crystallize octaphenylcyclotetrasiloxane, then filter with a 500-mesh filter cloth, centrifuge the filter cake at a speed of 2000 rpm for 30 minutes, and spin dry it at -0.099MPa and 40°C After 4 hours, the water and methanol adsorbed on the surface were removed to obtain dry needle-shaped crystals, namely octaphenylcyclotetrasiloxane, weighing 889g, yield 97.48%, content detected by liquid chromatography 99.3%, melting point 203°C.

Embodiment 2

[0028] Add 1000g of diphenylsilanediol with a mass percentage of 99.5% and 2000g of methanol into a 5L three-necked flask, stir until completely dissolved, add 0.3g of sodium hydroxide, heat the solution to 62°C, reflux for 5h; cool to room temperature, Stand still for 6 hours to fully crystallize octaphenylcyclotetrasiloxane, then filter with 600-mesh filter cloth, centrifuge the filter cake at 1800 rpm for 40 minutes, and spin-dry it at -0.098MPa and 50°C After 4 hours, the water and methanol adsorbed on the surface were removed to obtain dry needle-shaped crystals, namely octaphenylcyclotetrasiloxane, weighing 896g, yield 98.24%, liquid chromatography detection content 99.5%, melting point 203°C.

Embodiment 3

[0030] Add 1000g of diphenylsilanediol with a mass percentage of 99.8% and 3000g of methanol into a 5L three-necked flask, stir until completely dissolved, add 2g of potassium hydroxide, heat the solution to 64°C, reflux for 6h; cool to room temperature, Stand still for 8 hours to fully crystallize octaphenylcyclotetrasiloxane, then filter with 800-mesh filter cloth, centrifuge the filter cake at 1600 rpm for 45 minutes, and spin-dry it at -0.095MPa and 60°C After 5 hours, the water and methanol adsorbed on the surface were removed to obtain dry needle-shaped crystals, namely octaphenylcyclotetrasiloxane, weighing 892g, yield 97.81%, liquid chromatography detection content 99.7%, melting point 203°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com