Testing apparatus and method for actual high-pressure adsorption kinetics of adsorbent

A high-pressure adsorption and testing device technology, applied in analytical materials, instruments, etc., can solve problems such as high-pressure kinetics without adsorbents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

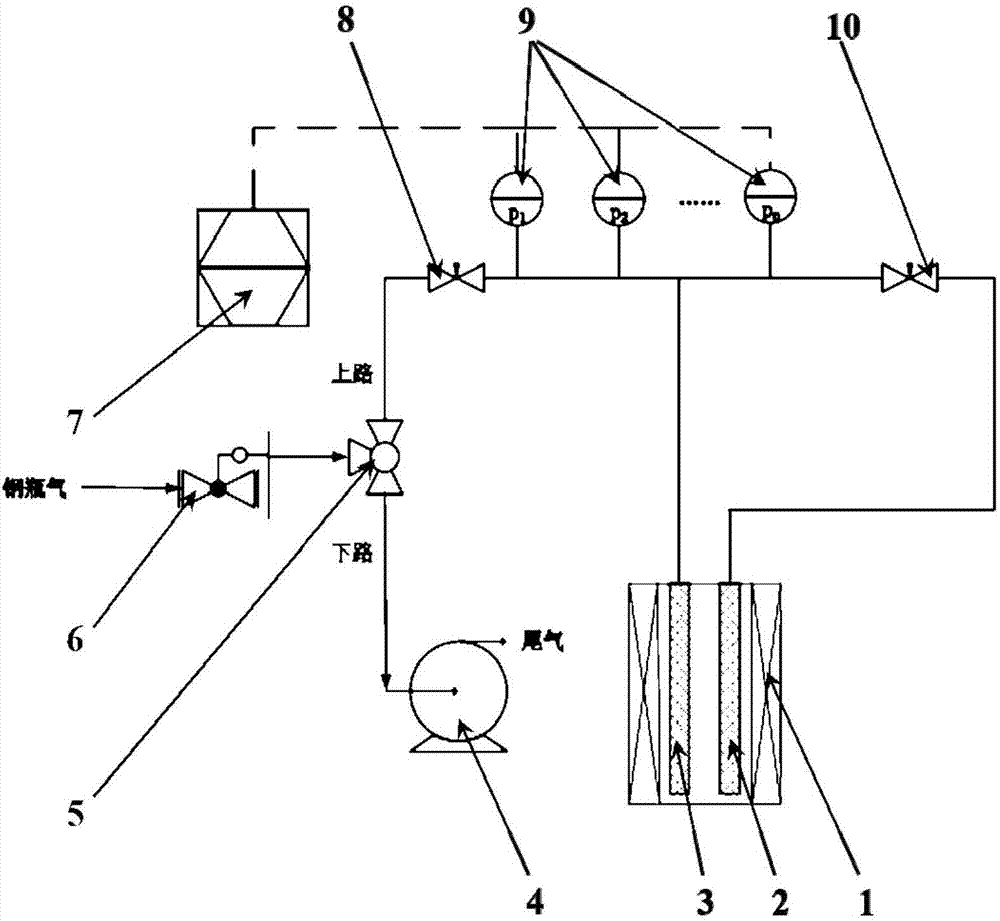

Method used

Image

Examples

Embodiment 1

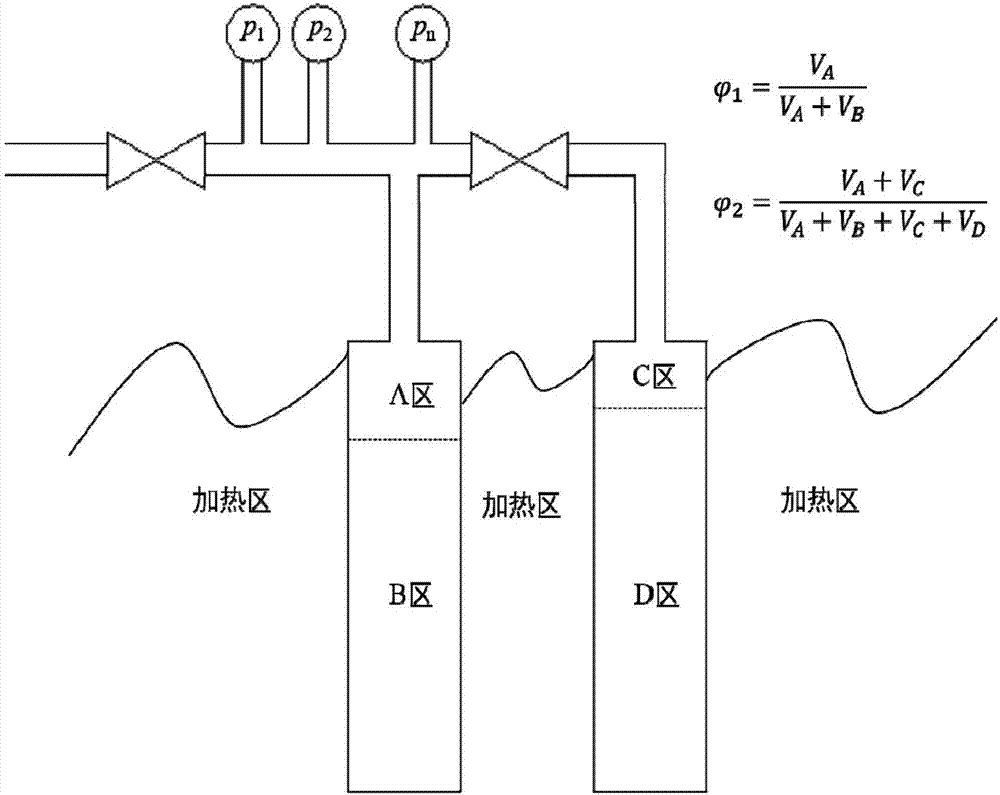

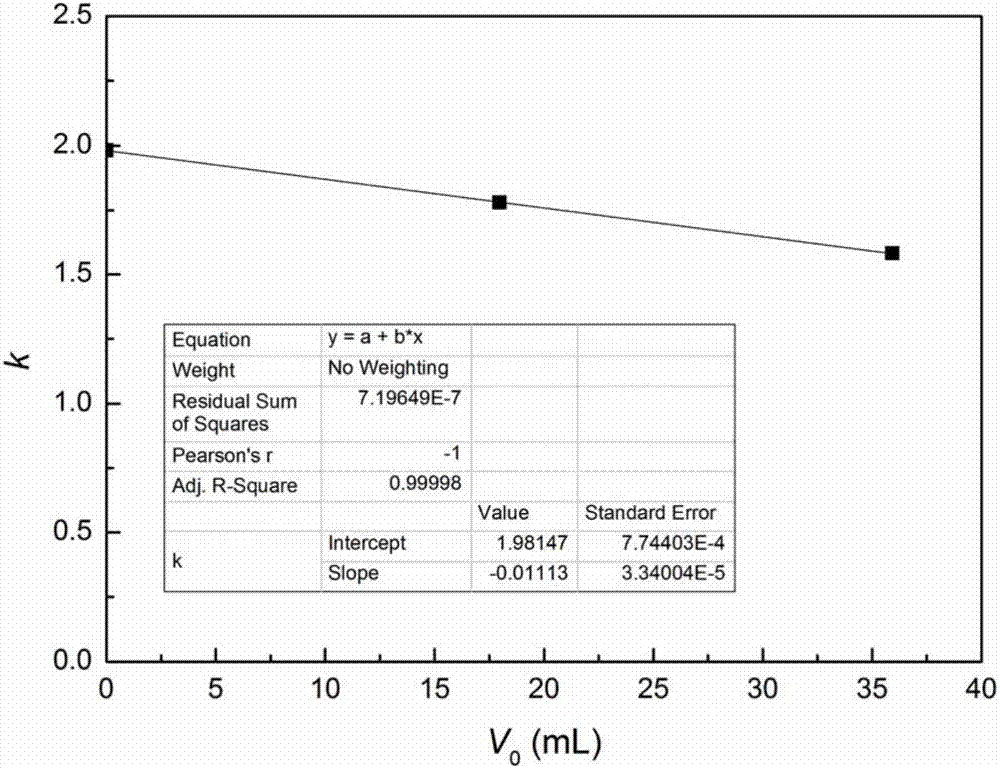

[0109] Use a steel ball with a diameter of 7mm to calibrate, and measure the adsorption tube V 2 2 without ball (V 0 =0), add 100 balls (V 0 =17.959mL), add 200 balls (V 0 =35.919mL) when p 1 and p 2 values, and the calculation results are shown in Table 1. Such as image 3 As shown, linear regression was performed on the results, and a=-0.0111, b=1.9815, and a correlation coefficient of 1 were obtained. Calculate V 1 and V 2 90.09mL and 88.42mL, respectively.

[0110] The high-pressure adsorption kinetics of activated carbon was tested at room temperature, and the activated carbon used was Taixi anthracite columnar activated carbon. Leak detection is carried out before the experiment, and the leak detection gas is CO 2 , test temperature T 2 is 288.15K, pressure p 1 It is 1.078MPa, and the leak detection time is 70h. For the leak detection results, see Figure 4 . Analyzing the data, the leak rate δ is 0.05 bar / h.

[0111] Since the test temperature is room tem...

Embodiment 2

[0115] Using the same testing device as in Example 1, the potassium-modified hydrotalcite K-MG30 (Sasol Germany GmbH) was subjected to high-pressure CO at 400°C. 2 Adsorption kinetics were studied. Room temperature T 0 It is 288.15K. Use 30 standard steel balls with a diameter of 7mm (total volume 5.388mL) for hot zone and cold zone calibration. To the adsorption tube V 1 3 and adsorption tube V 2 2 filled with helium pressure p 1 is 1.114MPa, raise it to T 2 (691.15K), get p 2 and p 3 They are 2.252MPa and 2.262MPa respectively. For the temperature rise curve during calibration, see Figure 6 .

[0116] at T 2 Downward adsorption tube V 1 3 respectively filled with pressure p 41.078, 2.132, 3.347MPa CO 2 , measure the corresponding p 5 They are 0.575, 1.149, 1.826MPa respectively. Based on the above data, the hot zone and the cold zone were calibrated, and the results are shown in Table 2. The temperature T of the cold zone is determined by comparison 1 is 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com