Zirconium-free spinel crystalline opaque glaze and manufacturing method

A technology of zirconium spinel and manufacturing method, which is applied in the field of ceramic glazes, can solve problems affecting the next generation, scarcity of resources, discoloration of glaze surfaces, etc., achieve wear resistance and scratch resistance, reduce production costs, and have high glaze hardness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

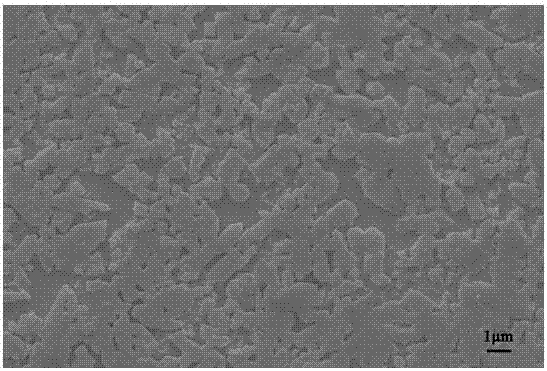

Image

Examples

Embodiment 1

[0026] The zirconium-free spinel microcrystalline opacity glaze of the present embodiment is made up of the component of following weight fraction: Na 2 O: 1.79%; K 2 O: 2.68%; Al 2 o 3 : 23.21%; CaO: 3.57%; MgO: 8.93%; ZnO: 6.25%; 2 o 3 : 3.57%; SiO 2 : 50.00%.

[0027] Calculate the raw material formula used according to the above formula ratio, select 30.0 parts by weight of potassium feldspar, 5.1 parts by weight of albite, 4.4 parts of calcite, 8.1 parts by weight of quartz powder, 24.6 parts by weight of talc, 6.0 parts by weight of boric acid, 15.8 parts by weight of alumina and 6.0 parts by weight of calcined zinc oxide were used as raw materials, uniformly mixed, melted at 1480° C. for 60 minutes, then water quenched, and ball milled to obtain frit powder. Mill 100g of frit powder, 5g of kaolin, 0.3g of carboxymethyl cellulose, 0.3g of sodium tripolyphosphate, and 60ml of water ball, pass through a 250-mesh sieve, and sieve 0.1g, add water to adjust the density ...

Embodiment 2

[0031] The zirconium-free spinel microcrystalline opacity glaze of the present embodiment is made up of the component of following weight fraction: Na 2 O: 1%; K 2 O: 5%; Al 2 o 3 : 20%; CaO: 5%; MgO: 14%; ZnO: 5%; 2 o 3 : 6%; SiO 2 : 44%.

[0032] Calculate the raw material formula used according to the above formula ratio, select 38.9 parts by weight of potassium feldspar, 6.1 parts by weight of calcite, 31.5 parts by weight of talc, 9.5 parts by weight of boric acid, 9.5 parts by weight of aluminum oxide, and 4.5 parts by weight of calcined zinc oxide in the present embodiment. The raw materials are uniformly mixed, melted at 1480°C for 45 minutes, then quenched with water, and ball milled to obtain frit powder. Mill 100g of frit powder, 3g of kaolin, 0.5g of carboxymethyl cellulose, 0.5g of sodium tripolyphosphate, and 60ml of water ball, pass through a 250-mesh sieve, and sieve 0.1g, add water to adjust the density of the glaze slurry to 1.55 g when glazing / cm 3 ...

Embodiment 3

[0035] The zirconium-free spinel microcrystalline opacity glaze of the present embodiment is made up of the component of following weight fraction: Na 2 O: 3%; K 2 O: 3%; Al 2 o 3 : 22.5%; CaO: 4.5%; MgO: 11%; ZnO: 6.5%; 2 o 3 : 4%; SiO 2 : 45.5%.

[0036] Calculate the raw material formula used according to the above formula ratio, select 30.0 parts by weight potassium feldspar, 15.2 parts by weight albite, 5.3 parts by weight calcite, 26.7 parts by weight talc, 6.6 parts by weight boric acid, 10.1 parts by weight alumina, 6.1 parts by weight of calcined zinc oxide was used as raw material, uniformly mixed, melted at 1490° C. for 50 minutes, then quenched with water, and ball milled to obtain frit powder. Mill 100g of frit powder, 4g of kaolin, 0.35g of carboxymethyl cellulose, 0.35g of sodium tripolyphosphate, and 60ml of water ball, pass through a 250-mesh sieve, and sieve 0.1g, and add water to adjust the density of the glaze slurry to 1.50 g when glazing / cm 3 , s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com