Bio-organic fertilizer based on waste clay and application of bio-organic fertilizer

A bio-organic fertilizer and waste white clay technology, applied in the field of bio-organic fertilizer, can solve the problems of not improving soil structure and solidifying heavy metals in soil, so as to shorten the decomposing period, reduce the occurrence of soil-borne diseases, and improve cold resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

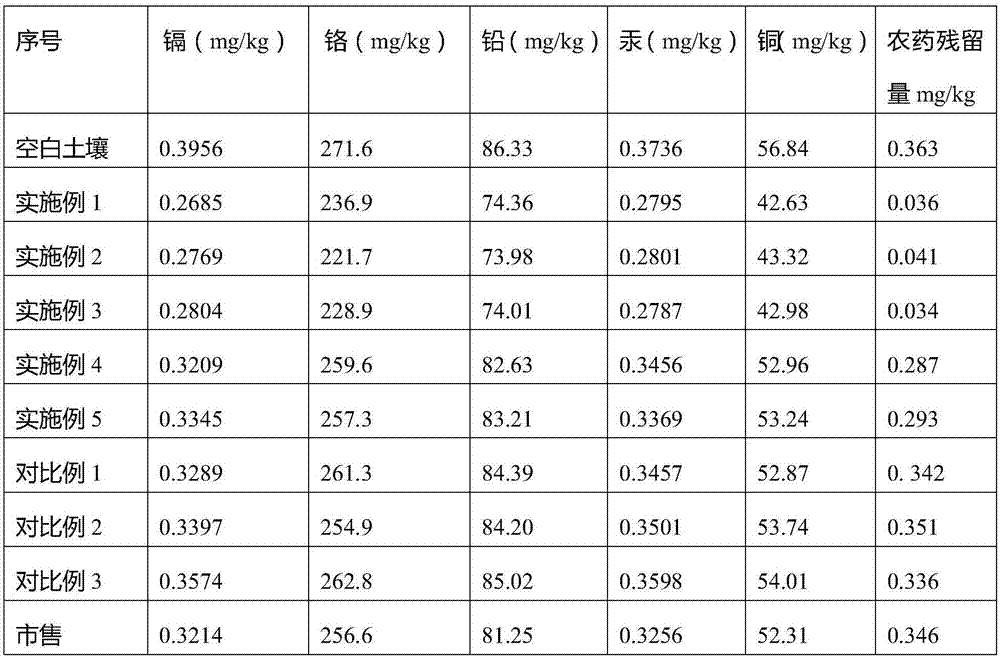

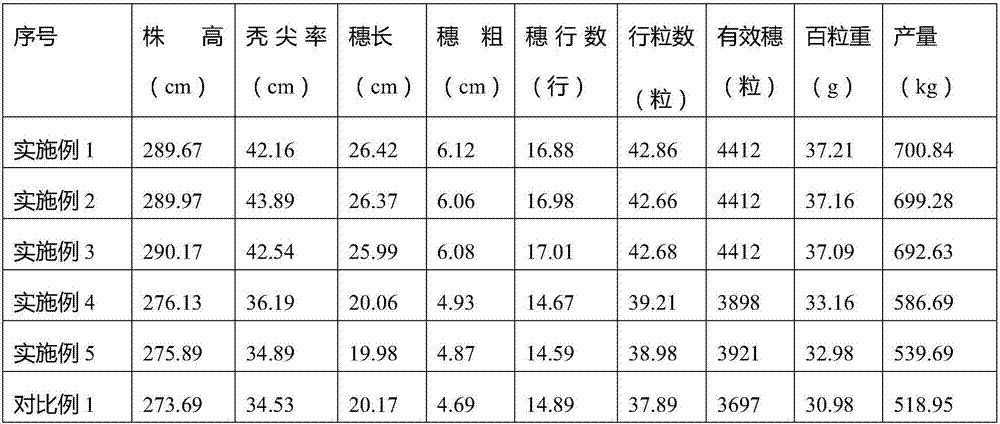

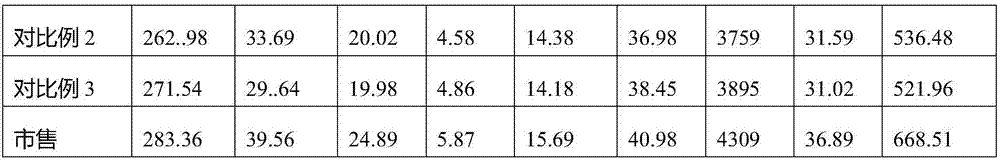

Examples

Embodiment 1

[0026] This example provides a kind of bio-organic fertilizer, in parts by weight, its raw material formula includes 60 parts of waste white clay, 12.4 parts of humic acid, 1.2 parts of compound bacteria liquid, 1 part of compound enzyme, 7.5 parts of magnesium aluminum silicate and brassin 0.1 part of lactone, wherein the oil content of waste clay is about 13-14%. Each component is individually packaged.

[0027] Before use, make an organic fertilizer according to the following steps: first sterilize the waste clay, then add humic acid and magnesium aluminum silicate to the waste clay and stir evenly, add the compound enzyme to the waste clay, stir evenly, and then Control the temperature between 28-35°C, then add the compound bacteria solution and brassinolide into the well-mixed waste clay and stir evenly, control the temperature between 28-35°C for 3 days, and then turn over Heap it once and keep it for 3 days.

Embodiment 2

[0029] This example provides a kind of bio-organic fertilizer, in parts by weight, its raw materials include 55 parts of waste clay, 15 parts of humic acid, 1.2 parts of compound bacteria liquid, 0.8 parts of compound enzyme, 10 parts of magnesium aluminum silicate and brassinolide 0.2 parts of ester, wherein the oil content of waste clay is about 13-14%. Each component is individually packaged.

[0030] Before use, according to the method identical with embodiment 1, make organic fertilizer.

Embodiment 3

[0032] This example provides a kind of bio-organic fertilizer, in parts by weight, its raw materials include 65 parts of waste clay, 10 parts of humic acid, 1.2 parts of compound bacteria liquid, 0.8 parts of compound enzyme, 5 parts of magnesium aluminum silicate and brassinolide 0.2 parts of ester, wherein the oil content of waste clay is about 13-14%. Each component is individually packaged.

[0033] Before use, according to the method identical with embodiment 1, make organic fertilizer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com