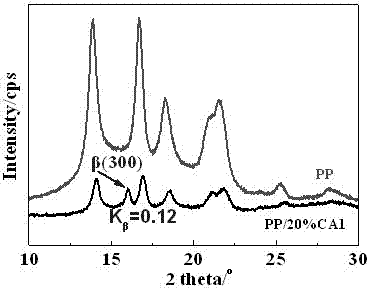

Charring agent with beta-crystal inducing nucleation effect, and synthetic method thereof

A technology of nucleation and synthesis method, which is applied in the field of intumescent flame retardant products, can solve problems such as low char formation, poor thermal stability, and great influence on mechanical properties, achieve high char formation rate, improve mechanical properties, and reduce absorption tidal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

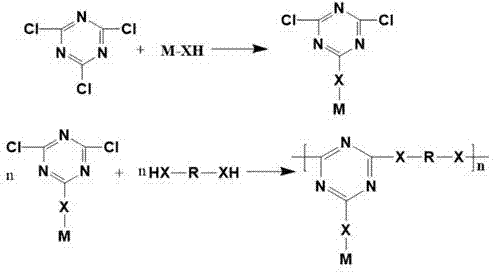

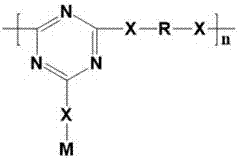

Method used

Image

Examples

Embodiment 1

[0027] In a 500ml three-necked bottle equipped with a thermometer, a stirrer, and a constant pressure dropping funnel, add 36.90 g (0.2 mol) of cyanuric chloride, then add 100 ml of acetone, place the three-necked bottle in an ice bath, and stir fully to make Cyanuric chloride is evenly dispersed, and a mixture of 18.62g (0.2mol) of aniline and 20.24g (0.2mol) of triethylamine is added dropwise to the three-necked flask, the reaction temperature is controlled at -5 - 5°C, and the reaction time is 1 -2 hours, add water to precipitate, wash, and dry in vacuum to obtain a monobasic substitute for cyanuric chloride.

[0028] Add cyanuric chloride monobasic substitute (0.2 mol) into a 500mL three-necked flask equipped with a reflux heating and cooling tube, a stirrer, and a constant-pressure dropping funnel, and drop 12.02 g (0.2mol) into the three-necked flask with a constant-pressure funnel. The mixture of ethylenediamine and 40.48g (0.4mol) triethylamine controls the dropping ra...

Embodiment 2

[0031] In a 500ml three-necked bottle equipped with a thermometer, a stirrer, and a constant pressure dropping funnel, add 92.25g (0.2mol) of cyanuric chloride, then add 100ml of acetone, place the three-necked bottle in an ice bath, and stir fully to make Cyanuric chloride is evenly dispersed, add 46.56g (0.2mol) cyclohexylamine dropwise to the three-necked bottle, dissolve 11.22g (0.1mol) triethylenediamine in 50ml distilled water, add dropwise with a constant pressure funnel, and control the pH at 5-7, the reaction temperature is controlled at -5-5°C, the reaction time is 1-2 hours, adding water to precipitate, washing, and vacuum drying to obtain a monobasic cyanuric chloride substitute.

[0032] Add cyanuric chloride monobasic substitute (0.2 mol) into a 500mL three-necked flask equipped with a reflux heating and cooling tube, a stirrer, and a constant-pressure dropping funnel, and drop 17.63g (0.2mol) into the three-necked flask with a constant-pressure funnel The mixtur...

Embodiment 3

[0034] In a 500ml three-necked bottle equipped with a thermometer, a stirrer, and a constant pressure dropping funnel, add 36.90 g (0.2 mol) of cyanuric chloride, then add 100 ml of acetone, place the three-necked bottle in an ice bath, and stir fully to make Cyanuric chloride is evenly dispersed, and a mixture of 18.62g (0.2mol) of aniline and 20.24g (0.2mol) of triethylamine is added dropwise to the three-necked flask, the reaction temperature is controlled at -5 - 5°C, and the reaction time is 1 -2 hours, add water to precipitate, wash, and dry in vacuum to obtain a monobasic substitute for cyanuric chloride.

[0035] Add cyanuric chloride monobasic substitute (0.2 mol) into a 500mL three-necked flask equipped with a reflux heating and cooling tube, a stirrer, and a constant-pressure dropping funnel, and add 22.02 g (0.2mol) dropwise to the three-necked flask with a constant-pressure funnel. The mixture of hydroquinone and 40.48g (0.4mol) triethylamine controls the dropping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com