Method for preparing nitrogen-doped carbon adsorbents for adsorbing CO2

A technology of nitrogen doping and carbon adsorption is applied in the field of preparation of nitrogen-doped carbon adsorbents, which can solve the problems of large influence on product performance at temperature, unfavorable development, production and utilization, and increase of reaction cost, etc. The effect of regeneration and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

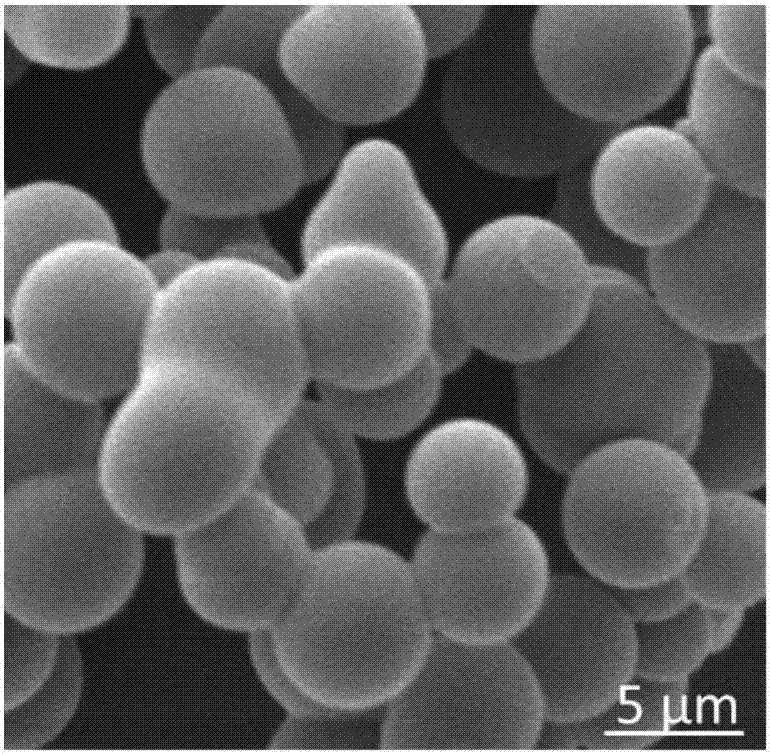

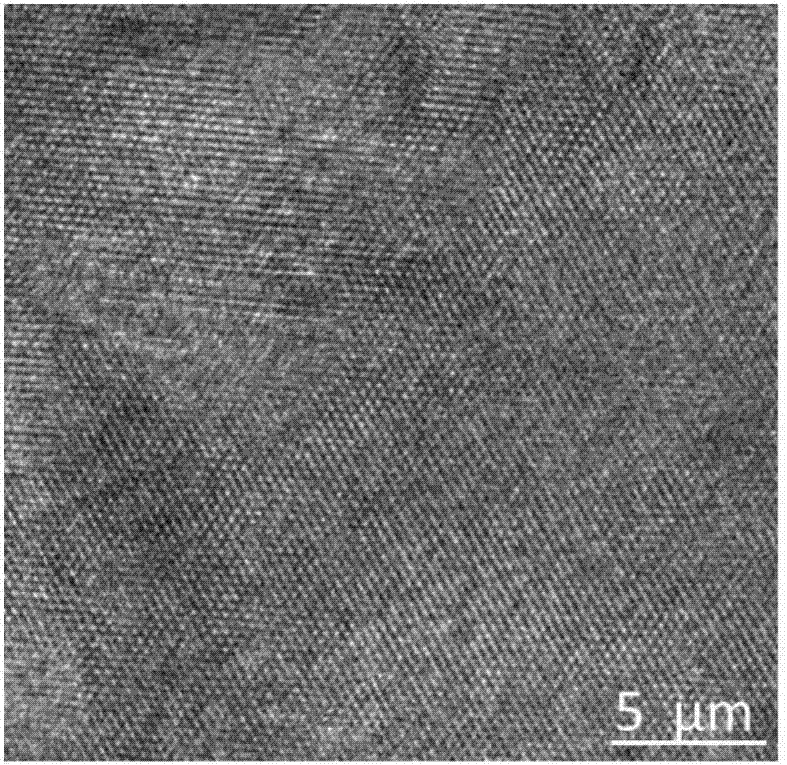

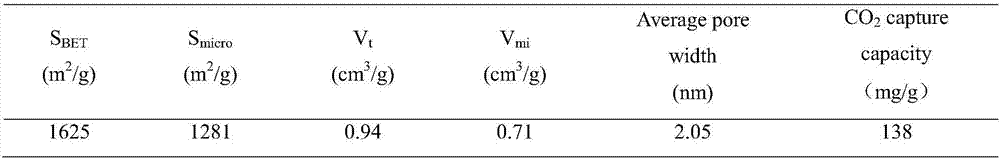

[0029] Grind poplar bark into wood flour, screen 40-60 mesh wood flour as raw material, take 3g of the above wood flour and dissolve it in 40ml aqueous solution, add urea as nitrogen source, the concentration is 4%, stir well and pour into polytetrafluoroethylene In the lined reactor, ensure that the ratio of the volume of the solution to the volume of the reactor is 3:5, heat up to 240°C and react at a constant temperature for 12 hours, cool down to room temperature, and centrifuge twice at a speed of 5000r / min to obtain a brown solid product. Wash with distilled water and absolute ethanol three times successively, and vacuum-dry at 80°C to obtain a nitrogen-doped hydrothermal carbon precursor, put it into a tube resistance furnace, raise the temperature to the target temperature of 800°C at 5°C / min, and keep the temperature for 2 hours to obtain Nitrogen-doped carbon adsorbent with well-developed microporous structure, with a specific surface area of 1625m 2 / g, the averag...

Embodiment 2

[0032] Grind poplar bark into wood powder, screen 40-60 mesh wood powder as raw material, take 4g of the above wood powder and dissolve in 50ml aqueous solution, add urea as nitrogen source, the concentration is 6%, stir well and pour into polytetrafluoroethylene In the lined reactor, ensure that the ratio of the volume of the solution to the volume of the reactor is 3:5, heat up to 260°C and react at a constant temperature for 10 hours, cool down to room temperature, and centrifuge twice at 8000r / min to obtain a brown solid product. Washed twice with distilled water and absolute ethanol successively, and vacuum-dried at 80°C to obtain a nitrogen-doped hydrothermal carbon precursor, put it into a tube resistance furnace, raise the temperature to the target temperature of 900°C at 5°C / min, and keep the temperature for 1.5h. A nitrogen-doped carbon adsorbent with well-developed microporous structure was obtained, with a specific surface area of 1755m 2 / g, the average pore dia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com