Vanadium nitride material and preparation method and application thereof

A vanadium nitride material and technology of vanadium nitride, applied in chemical instruments and methods, nitrogen compounds, nitrogen-metal/silicon/boron binary compounds, etc., can solve uneven distribution, small specific surface area of vanadium nitride, dispersion Poor properties and other problems, to achieve the effect of uniform pore size distribution, increased specific surface area, and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] (1) Add 5wt% zinc nitrate solution dropwise to 100mmol / L ammonium metavanadate solution, control the molar ratio of V / Zn to be 3:2, stir well and then age in a water bath at 30°C for 8h to obtain the mixture ;

[0058] (2) The mixture obtained in step (1) is filtered, and the precipitate obtained is washed and dried to obtain Zn 3 (OH) 2 (V 2 o 7 )(H 2 O) 2 ;

[0059] (3) the Zn that step (2) obtains 3 (OH) 2 (V 2 o 7 )(H 2 O) 2 Put it in a tube furnace, feed ammonia gas, control the flow rate of ammonia gas to 150mL / min, raise the temperature to 650°C at a rate of 5°C / min and calcinate for 8h, and obtain vanadium nitride material after reduction and nitriding.

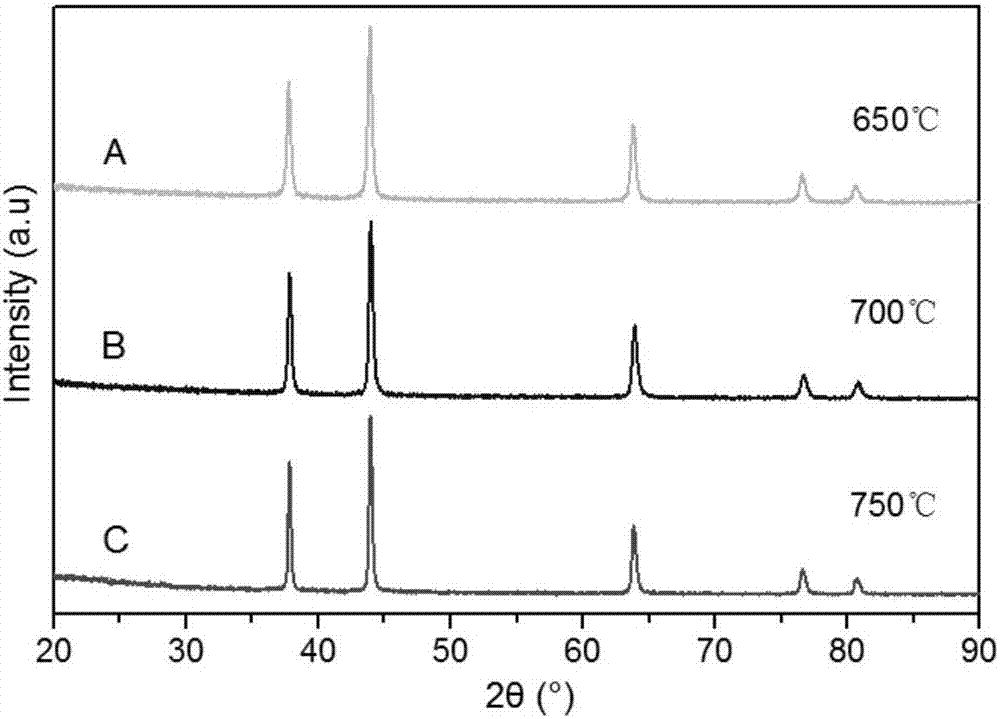

[0060] Carry out XRD characterization to the vanadium nitride material prepared in this embodiment, as figure 1 As shown in Figure A, the vanadium nitride material obtained in this embodiment is pure phase VN.

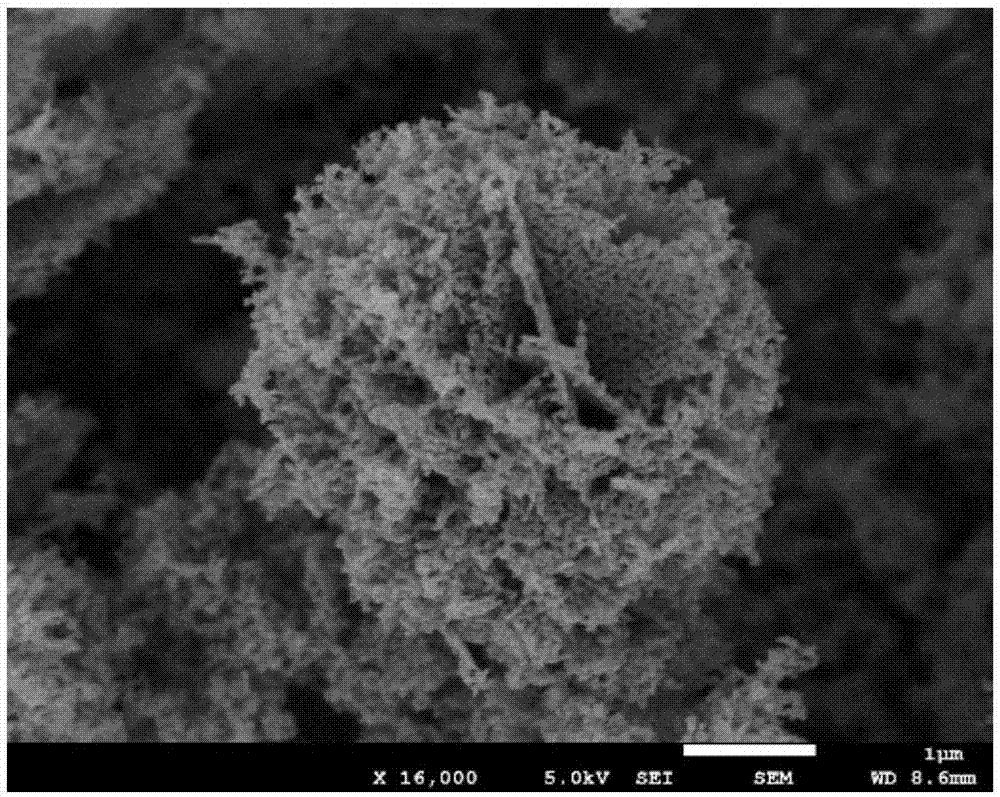

[0061] Carry out SEM characterization to the vanadium nitride material prepared in thi...

Embodiment 2

[0064] (1) Add 5wt% zinc chloride solution dropwise to 80mmol / L sodium metavanadate solution, control the molar ratio of V / Zn to 3:2, stir well and age in a water bath at 30°C for 6h to obtain the mixture ;

[0065] (2) The mixture obtained in step (1) is filtered, and the precipitate obtained is washed and dried to obtain Zn 3 (OH) 2 (V 2 o 7 )(H 2 O) 2 ;

[0066] (3) the Zn that step (2) obtains 3 (OH) 2 (V 2 o 7 )(H 2 O) 2Place in a tube furnace, feed a mixed gas of ammonia and nitrogen, the volume fraction of ammonia is 90%, the flow rate of the mixed gas is controlled at 150mL / min, and the temperature is raised to 700°C at a rate of 5°C / min for calcination for 12h. The vanadium nitride material is obtained after reduction and nitriding.

[0067] Carry out XRD characterization to the vanadium nitride material prepared in this embodiment, as figure 1 As shown in Figure B, the vanadium nitride material obtained in this embodiment is pure phase VN.

[0068] Car...

Embodiment 3

[0071] (1) 5wt% zinc nitrate solution was added dropwise to 100mmol / L sodium orthovanadate solution, the molar ratio of V / Zn was controlled to 3:2, after stirring evenly, aging in 30°C water bath for 8h, to obtain the mixture;

[0072] (2) The mixture obtained in step (1) is filtered, and the precipitate obtained is washed and dried to obtain Zn 3 (OH) 2 (V 2 o 7 )(H 2 O) 2 ;

[0073] (3) Zn obtained by step (2) 3 (OH) 2 (V 2 o 7 )(H 2 O) 2 Place in a tube furnace, feed a mixed gas of ammonia and argon, the volume fraction of ammonia is 85%, control the flow rate of the mixed gas to 150mL / min, and heat up to 750°C at a rate of 5°C / min for calcination for 8h , the vanadium nitride material is obtained after reduction and nitriding.

[0074] Carry out XRD characterization to the vanadium nitride material prepared in this embodiment, as figure 1 As shown in Figure C, the vanadium nitride material obtained in this embodiment is pure phase VN.

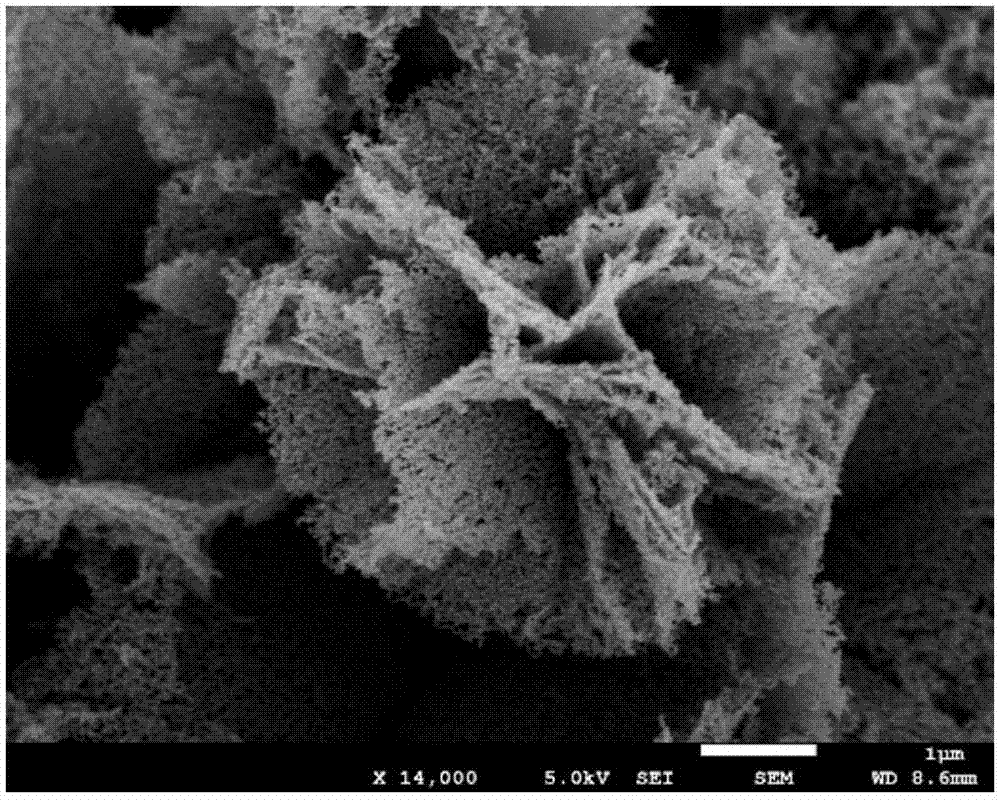

[0075] Carry out SEM c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com