Terpene synthase for producing koraiol and application of terpene synthase

A technology of terpene synthase and gene, which is applied in the field of terpene synthase for the production of sesquiterpene compound-koraiol, can solve the problems of high production cost and poisonous chemical synthesis method, and achieve reduction of research cost, increase of output, Overcoming the effect of low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

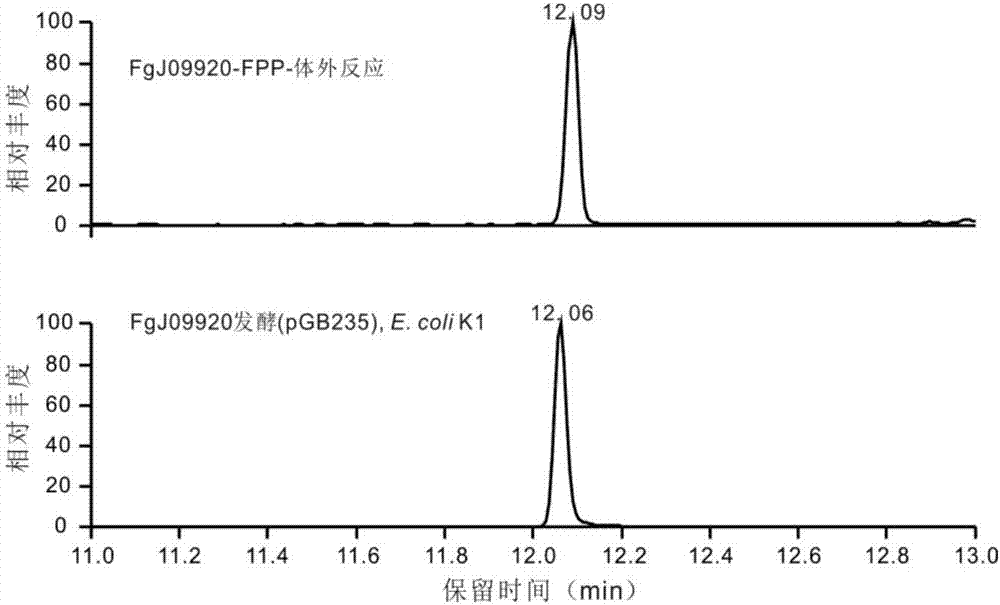

[0029] [Example 1] Verification of the function of terpene synthase in vitro

[0030] 1. Construction of plasmid pGB28a-FgJ09920

[0031] Using the reverse-transcribed Fusarium graminearum J1-012 cDNA as a template, the obtained coding region FgJ09920 was amplified with primers P27 / P29 (see Table 1), and connected to the plasmid pET28a to obtain the plasmid pGB28a-FgJ09920 ( Figure 4 ), for protein purification.

[0032] 2. Protein purification

[0033] Transform the expression vector pET28a-FgJ9920 containing the target gene (nucleotide sequence shown in SEQ ID NO: 2) into the expression host E.coli BL21(DE3), and pick a single clone into the LB medium containing the corresponding antibiotics after transformation , 37°C, 220rpm overnight culture. Transfer to 1L of fresh LB medium containing corresponding antibiotics according to 1% inoculum amount, and cultivate to OD at 37°C and 220rpm 600 About 0.6-0.8, lower the temperature to 16°C, add IPTG with a final concentration...

Embodiment 2

[0039] [Example 2] Construction of expression vector

[0040] Escherichia coli XL1-blue genomic DNA and Saccharomyces cerevisiae INVSC1 genomic DNA were purified with Qiagen's Blood and Cell Culture DNA Mini Kit.

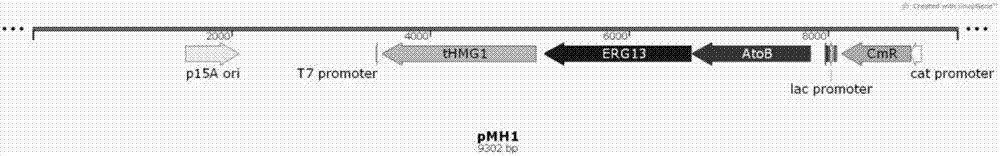

[0041] Plasmid pMH1 contains the first three genes of the mevalonate pathway: atoB gene (acetoacetyl-CoA thioesterase, AM946981.2) from E. coli XL1-blue, erg13 (HMG-CoAsynthase, CP005477 .2) and tHMG1 (HMG-CoA reductase, deletion of the transmembrane region of HMG1, CP005464.2).

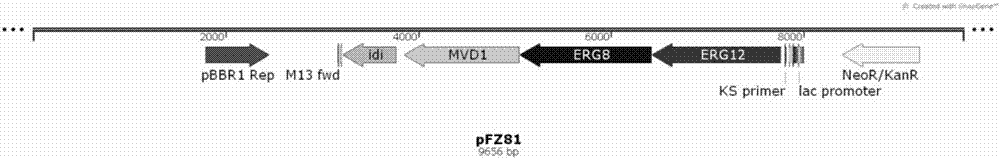

[0042] Plasmid pFZ81 contains the last four genes of the mevalonate pathway: erg12 (mevalonate kinase, CP008027.1), erg8 (mevalonate-5-phosphate kinase, CP005426.1) and mvd1 from S. cerevisiae INVSC1 (Mevalonate-5-pyrophosphate kinase, CP005554.2), derived from the idi (isopentenyl pyrophosphate isomerase, CP010152.1) gene of Escherichia coli XL1-blue.

[0043] Plasmid pGB235 contains three genes for the synthesis of sesquiterpene compounds, which are respectively FgJ09920 (SEQ ID NO: 2)...

Embodiment 3

[0058] [Example 3] Escherichia coli in vivo synthesis of sesquiterpene compounds derived from FgJ09920

[0059] In order to produce sesquiterpene compounds, the two plasmids pMH1 and pFZ81 of the mevalonate pathway were simultaneously transformed into Escherichia coli BL21(DE3) to obtain BL21(DE3) / pMH1 / pFZ81, which was named PS, and then pGB235 was transformed into the strain In PS, obtain strain K1, and then pick single clones into 10 mL LB medium (contains 100 μg / mL ampicillin, 50 μg / mL kanamycin and 34 μg / mL chloramphenicol at the same time), 37 ° C, 220 rpm overnight Cultivate, and then inoculate 1% inoculum into the same fresh medium at 37°C, 220rpm and continue to cultivate to OD 600 At about 0.6 to 0.8, lower the temperature to 16°C and add IPTG with a final concentration of 0.1mM to induce expression, induce expression for 18 hours, then raise the temperature to 28°C for 72 hours of fermentation, then ferment and extract the product, collect the bacteria and fermentati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com