Low specific gravity composite thermally-conductive insulating glue and preparation method thereof

A heat-conducting, insulating, and low-specific-gravity technology, applied in the direction of adhesives, epoxy resin glue, adhesive types, etc., can solve problems such as high density of epoxy resin, adverse environmental effects, and affecting the bonding performance of epoxy resin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The application also provides a preparation method of the composite thermally conductive insulating adhesive, including:

[0032] The filler, the coupling agent and the epoxy resin are mixed, and then a curing agent is added for curing to obtain a composite thermally conductive insulating adhesive.

[0033] In order to make the raw materials mix more fully and effectively realize the full modification of the filler, the preparation process of the composite heat-conducting insulating adhesive is specifically as follows:

[0034] Mix the filler with a solvent, then add a coupling agent for ultrasonication, seal and dry to obtain a modified filler;

[0035] The modified filler is ultrasonically mixed with the epoxy resin, and after three-roll grinding, mixed with a curing agent, heated and cured to obtain a low specific gravity composite thermally conductive insulating adhesive.

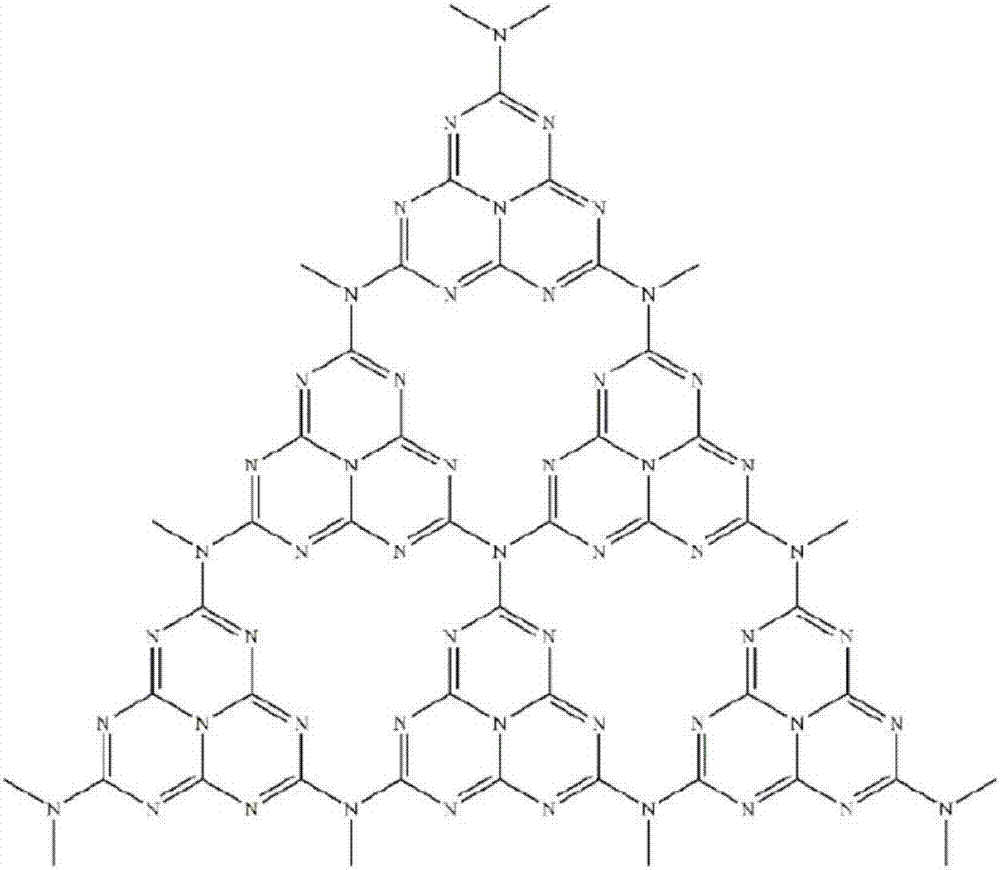

[0036] In the above process, the filler is graphite-like carbon nitride, which may also incl...

Embodiment 1

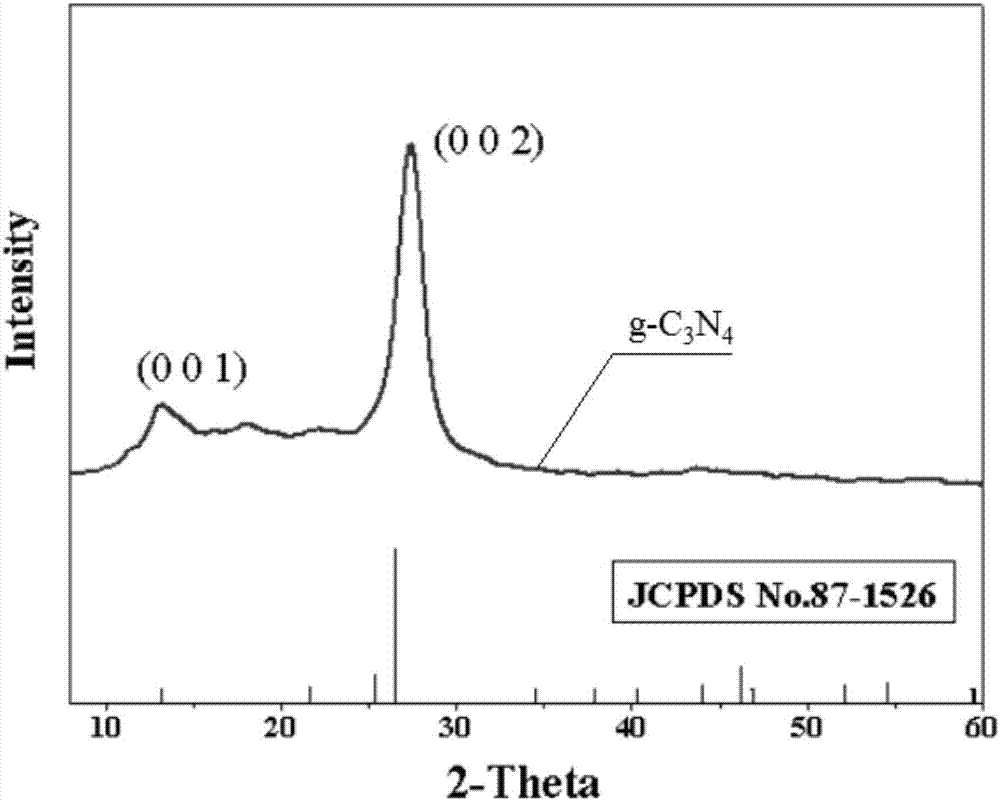

[0044] Weigh 5g of melamine, put it in a corundum crucible and cover it, raise the temperature to 550°C in a tube furnace under a nitrogen atmosphere, and the heating rate is 3°C min -1 , and calcined at 550°C for 4h, cooled naturally to room temperature to obtain a light yellow solid, which was ground to obtain graphite-like carbon nitride (g-C 3 N 4 ). figure 2 For the XRD spectrum of the graphite-like carbon nitride prepared in this example, Table 1 is the element content analysis table of the graphite-like carbon nitride prepared in this example.

[0045] Table 1 The elemental content analysis table of the graphite-like carbon nitride prepared in this embodiment

[0046] element C H N content(%) 33.75 1.34 60.38

[0047] The graphitic carbon nitrides in the following examples were all prepared according to the method in Example 1.

Embodiment 2

[0049] 1) Weigh 3g to prepare g-C 3 N 4 , added to 50mL of ethanol and distilled water mixed solution with a volume ratio of 3:1, ultrasonicated for 25min, added 0.3g of silane coupling agent KH570, sealed with plastic wrap at 65°C, mechanically stirred for 4h, poured into a glass dish under natural conditions The solvent was evaporated for 12 hours, dried in an oven to obtain surface-modified g-C 3 N 4 Modified filler;

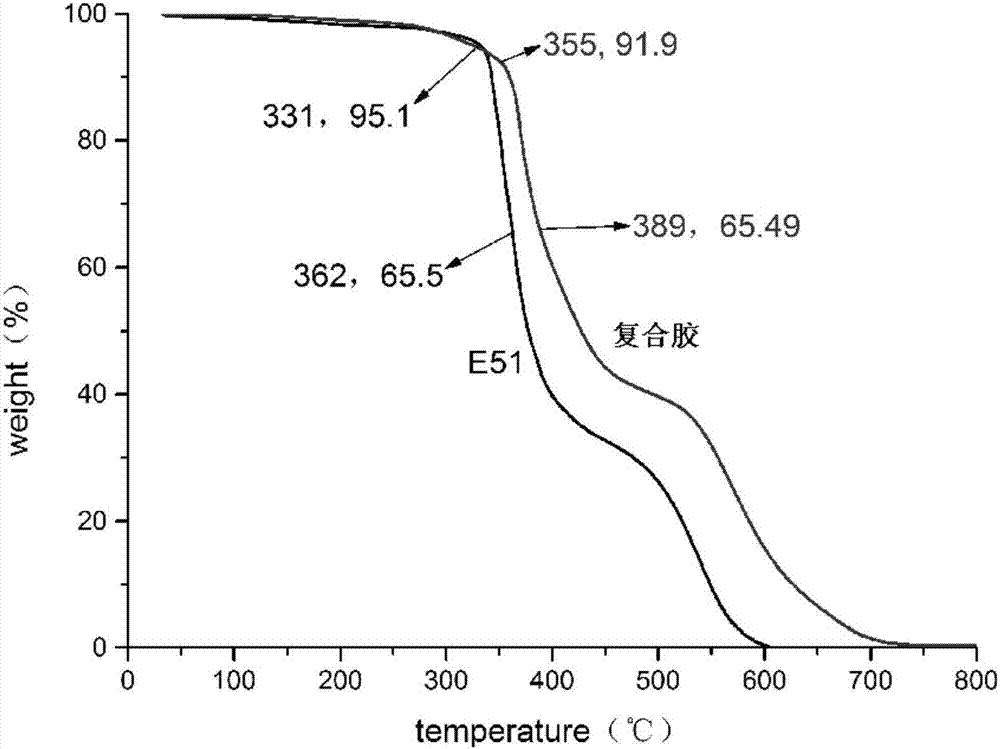

[0050] 2) Weigh 20 parts of the modified filler prepared in step 1, add it to 80 parts of epoxy resin E51, heat and stir at 65°C for 5 hours, add 0.5 parts of curing agent ethylenediamine after three-roll grinding, and mix well , remove air bubbles in a vacuum oven at 45°C for 15 minutes, remove air bubbles in the epoxy resin mixture, pour it into a prepared mold, remove air bubbles in a vacuum oven at 45°C, and cure for 24 hours to obtain a composite glue.

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com