Preparation method of three-dimensional modified graphene filter screen

A graphene and modification technology, applied in the field of preparation of three-dimensional modified graphene filter screen, can solve problems such as poor practicability, and achieve the effects of enhanced adsorption surface area, environmental friendliness, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The present invention is a kind of preparation method of three-dimensional modified graphene filter net, comprises the following steps:

[0023] a. Prepare foam metal;

[0024] b. Remove impurities and oxide layers on the surface of the foam metal by soaking in acid solution;

[0025] c. Use cobalt salt, nickel salt, graphene and water to form a solution as a dipping reagent;

[0026] d, soaking the metal foam through step b in the dipping reagent;

[0027] e. Drying the metal foam through step d;

[0028] f. Carrying out high-temperature heat treatment to the metal foam after step e, to decompose the cobalt salt and nickel salt loaded on the surface of the metal foam to obtain their composite oxides.

[0029] The method of the present invention first removes surface impurities and oxide layers, then performs solution dipping, and then dries, and coats the cobalt-nickel oxide active material and graphene on the surface of the foam metal to enhance the adsorption surf...

Embodiment example 1

[0035] A preparation method for a three-dimensional modified graphene filter, comprising the following steps:

[0036] 1) Take 6×6cm nickel foam and soak it in 0.05mol / L hydrochloric acid solution for 24 hours;

[0037] 2) Prepare 50ml of nickel acetate and cobalt acetate with a mixing molar ratio of 1:5, add 1wt% graphene, (nickel acetate mole is 1mmol, cobalt acetate mole is 5mmol);

[0038] 3) Ultrasonic immersion in the mixed solution for 0.5 minutes, take it out, and dry it in an oven at 80°C for one hour;

[0039] 4) heat-treating the nickel foam obtained in step 3) at 400° C. for 3 hours in an air atmosphere.

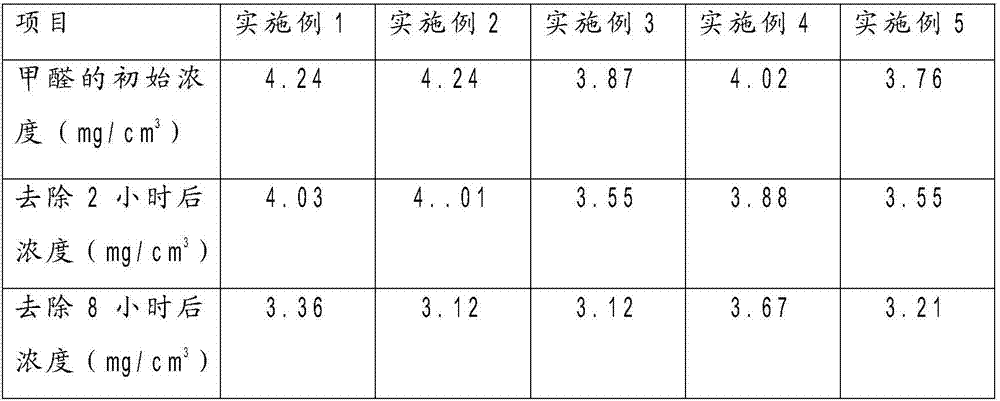

[0040] The three-dimensional modified graphene filter prepared in Example 1 was tested for its formaldehyde removal performance, and the results obtained are shown in Table 1 below.

Embodiment example 2

[0042] A method for preparing a three-dimensional modified graphene filter, comprising the following steps:

[0043] 1) Take 6×6cm foam nickel and soak it in 0.5mol / L hydrochloric acid solution for 2 hours;

[0044] 2) Prepare 50ml of nickel acetate and cobalt acetate with a mixing molar ratio of 1:0.1 (1 mmol of nickel acetate and 0.1 mmol of cobalt acetate) and add 1wt% graphene;

[0045] 3) Ultrasonic immersion in the mixed solution for 6 minutes, take it out, and dry it in an oven at 100°C for 1 hour;

[0046] 4) heat-treating the foamed nickel obtained in step 3) at 420° C. for 3 hours in an air atmosphere, and cobalt-nickel oxide is formed on the surface of the foamed nickel;

[0047] The three-dimensional modified graphene filter prepared in Example 2 was tested for its formaldehyde removal performance, and the results obtained are shown in Table 1 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com