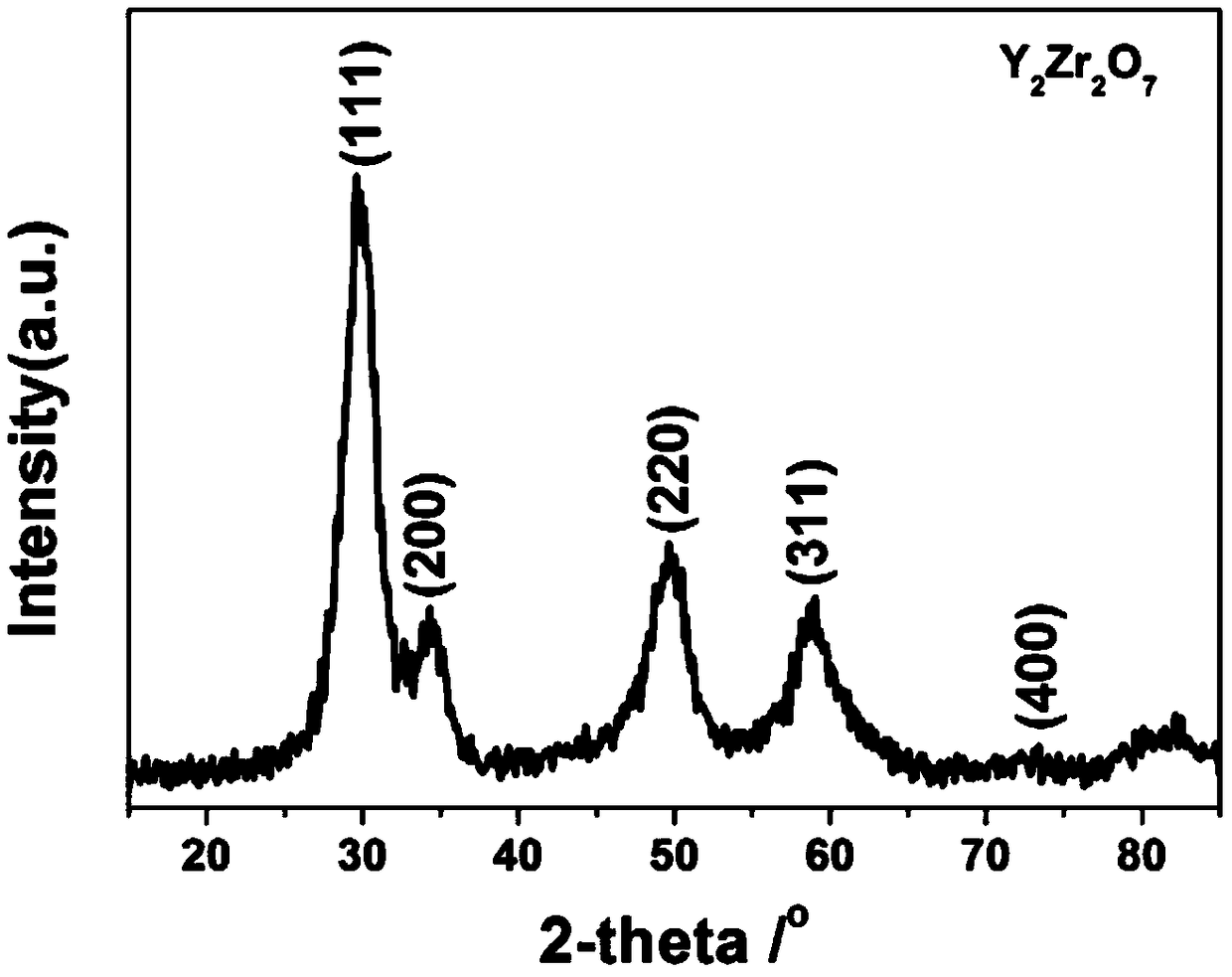

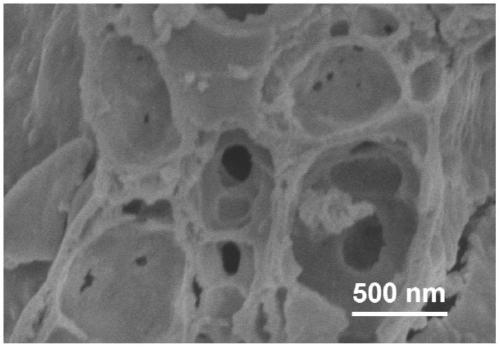

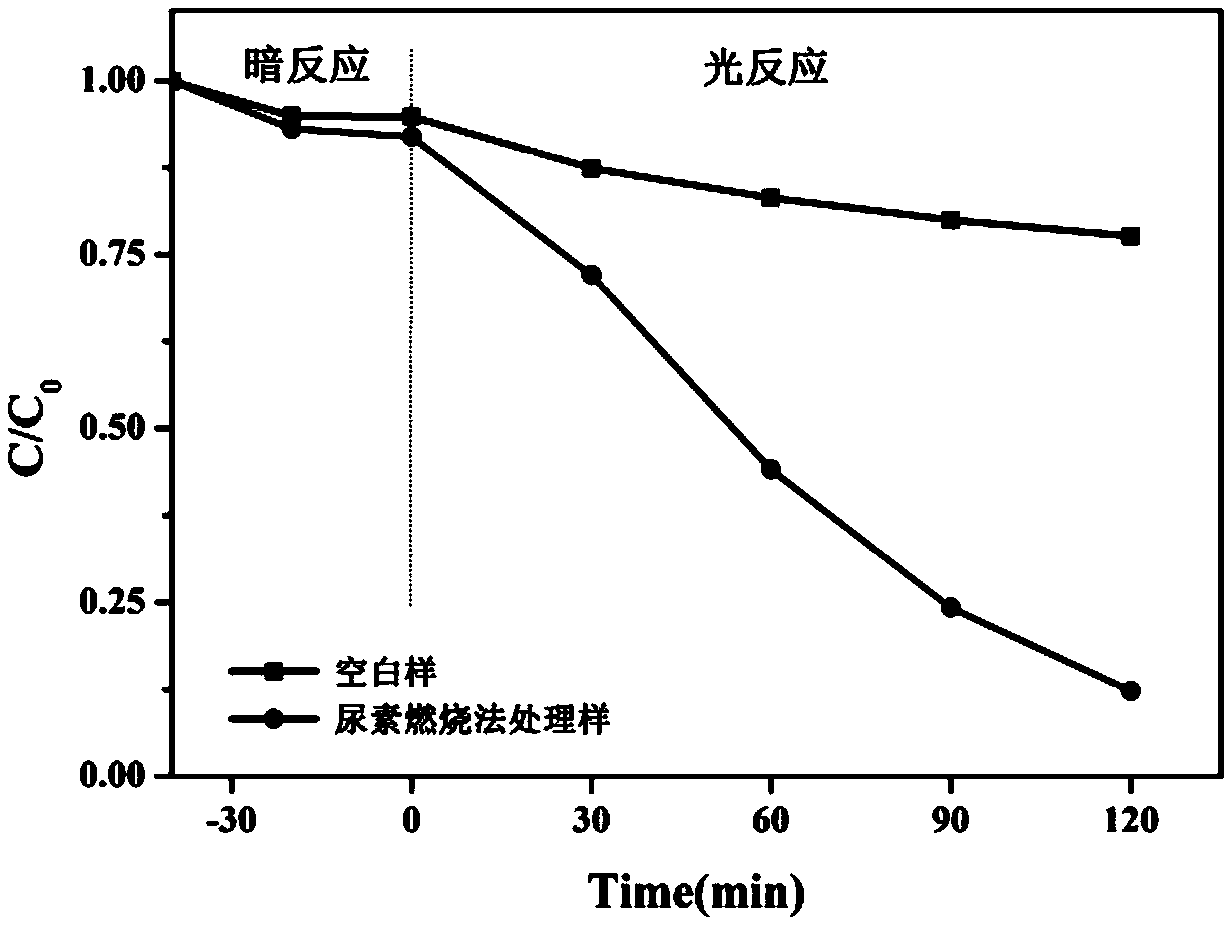

A method for preparing yttrium zirconate powder by nitrate-urea combustion method

A technology of yttrium zirconate and combustion method, which is applied in chemical instruments and methods, zirconium compounds, inorganic chemistry, etc., can solve the problems of high reaction temperature, large product size, stoichiometric loss, etc., and promotes low-temperature rapid synthesis. , The effect of less product loss and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1) Weigh the analytically pure Y(NO 3 ) 3 ·6H 2 O and Zr(NO 3 ) 4 ·5H 2 O was placed in a beaker and dissolved in deionized water to obtain Y(NO 3 ) 3 ·6H 2 Solution A and Zr(NO 3 ) 4 ·5H 2 O concentration is 0.025mol / L solution B, solution A and solution B are mixed to obtain Y(NO 3 )3 ·6H 2 O concentration is the mixed solution of 0.0125mol / L, wherein, the molar ratio of Y and Zr in the mixed solution is 1:1;

[0030] 2) Using urea as the combustion agent, add 1 mol / L urea solution into the uniformly stirred mixed solution by adding dropwise, in which the molar ratio of urea:Y=5:1 is maintained, and then slowly add concentrated ammonia water to adjust Its pH=6, and a mixed solution was obtained.

[0031] 3) Stir the mixed solution with a magnetic stirrer at a speed of 350 rpm for 0.5h to obtain a stable transparent sol, put the stable transparent sol into an ultrasonic instrument, control the temperature to 80°C, and the ultrasonic frequency to 40KHZ , t...

Embodiment 2

[0035] 1) Weigh the analytically pure Y(NO 3 ) 3 ·6H 2 O and Zr(NO 3 ) 4 ·5H 2 O was dissolved in a beaker with deionized water respectively to obtain solution A and solution B, and solution A and solution B were mixed to obtain Y (NO 3 ) 3 ·6H 2 O concentration is the mixed solution of 0.2mol / L, wherein, the molar ratio of Y and Zr in the mixed solution is 1:1;

[0036] 2) Using urea as the combustion agent, add 2mol / L urea solution into the uniformly stirred mixed solution by adding dropwise, and keep the molar ratio of urea:Y=6:1, and then slowly add concentrated ammonia water to adjust Its pH ranges to 5 to obtain a mixed liquor.

[0037] 3) Stir the mixed solution with a magnetic stirrer at a speed of 400 rpm for 1 hour to obtain a stable transparent sol, put the stable transparent sol into an ultrasonic instrument, control the temperature at 60°C, and the ultrasonic frequency at 40KHZ, The ultrasonic power was 1500W, and a white gel was obtained after ultrasonic...

Embodiment 3

[0044] 1) Weigh the analytically pure Y(NO 3 ) 3 ·6H 2 O and Zr(NO 3 ) 4 ·5H 2 O was dissolved in a beaker with deionized water respectively to obtain solution A and solution B, and solution A and solution B were mixed to obtain Y (NO 3 ) 3 ·6H 2 O concentration is the mixed solution of 0.1mol / L, wherein, the molar ratio of Y and Zr in the mixed solution is 1:1;

[0045] 2) Using urea as the combustion agent, add 1 mol / L urea solution into the uniformly stirred mixed solution by adding drop by drop, keep the molar ratio of urea:Y=7:1, and then slowly add concentrated ammonia water to adjust In the range of pH=4, a mixed solution is obtained.

[0046] 3) Stir the mixed solution with a magnetic stirrer at a speed of 450 rpm for 1 hour to obtain a stable transparent sol solution, put the stable transparent sol solution into an ultrasonic instrument, control the temperature at 60°C, and the ultrasonic frequency at 40KHZ, The ultrasonic power was 1500W, and a white gel was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com