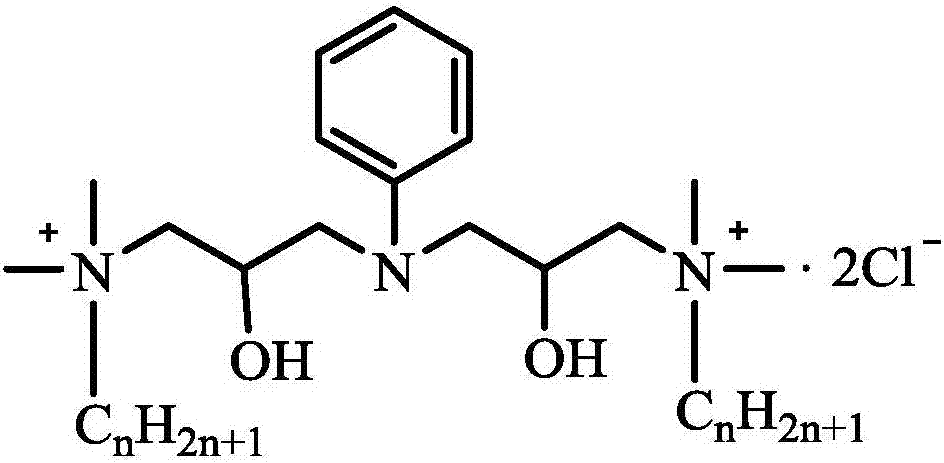

Gemini cationic asphalt emulsifier and preparation method thereof

A technology of asphalt emulsifier and cation, which is applied in chemical instruments and methods, preparation of organic compounds, preparation of amino hydroxyl compounds, etc., can solve problems such as increased production and construction costs, excessive use of emulsifiers, complex synthesis process, etc. Achieve the effects of overcoming the large amount of emulsifier, easy control of reaction conditions, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

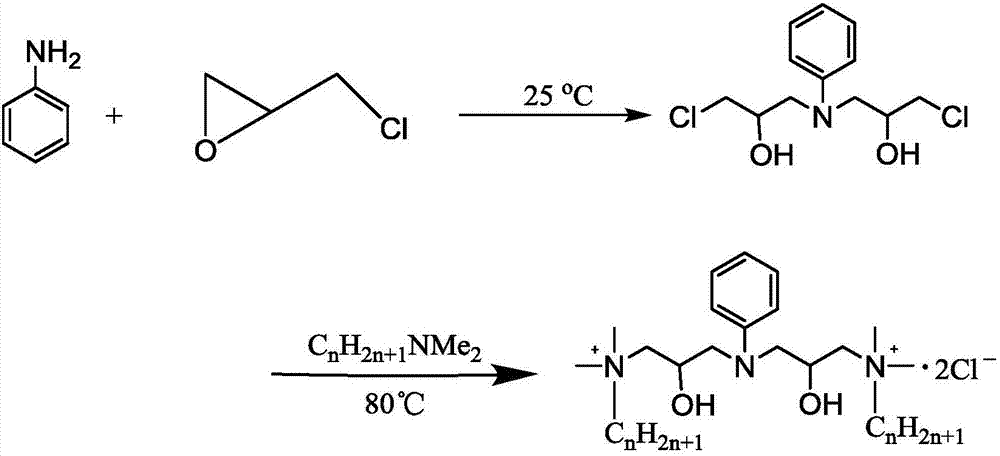

[0025] The preparation method of the gemini cationic asphalt emulsifier of twelve carbons, the concrete preparation steps are as follows:

[0026] At 25°C, 12.4g of aniline, 4ml of propionic acid, and 50ml of water were added to a single-necked flask, and the mixture was stirred for 15 minutes, then 28.27g of epichlorohydrin was added, and stirred for 18 hours. After the reaction was stopped, the layers were allowed to stand, and the water layer was removed. The obtained organic layer was washed with water, then recrystallized with ethyl acetate and petroleum ether, filtered with suction, and dried in vacuo. Intermediate I is obtained. Add 20.00g of dodecyldimethyl tertiary amine into the flask and stir. Dissolve 11.81g of intermediate I in absolute ethanol, add it dropwise into the flask, and reflux for 6 hours. Ethyl ester recrystallized. A twelve-carbon gemini cationic asphalt emulsifier is obtained.

Embodiment 2

[0028] The preparation method of the gemini cationic asphalt emulsifier of fourteen carbons, the concrete preparation steps are as follows:

[0029] At 25°C, 12.4g of aniline, 4ml of propionic acid, and 50ml of water were added to a single-necked flask, and the mixture was stirred for 15 minutes, then 28.27g of epichlorohydrin was added, and stirred for 18 hours. After the reaction was stopped, the layers were allowed to stand, and the water layer was removed. The obtained organic layer was washed with water, then recrystallized with ethyl acetate and petroleum ether, filtered with suction, and dried in vacuo. Intermediate I is obtained. 20.00g tetradecyl dimethyl tertiary amine was added into the flask and stirred, 9.35g of intermediate I was dissolved in absolute ethanol, added dropwise into the flask, and refluxed for 6 hours. Ethyl ester recrystallized. Fourteen carbon gemini cationic asphalt emulsifiers are obtained.

Embodiment 3

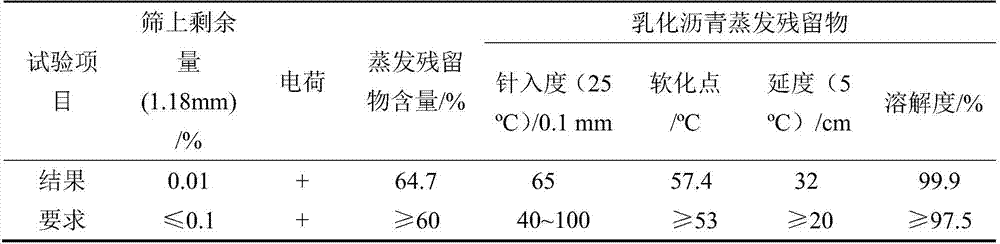

[0031] Preparation and performance test of emulsified asphalt:

[0032] Add 39 parts of warm water at 68°C to the beaker, then add 1 part of the emulsifier prepared in Example 1 into the warm water, and stir to prepare 40 parts of emulsifier aqueous solution. Add 60 parts of 140°C petroleum asphalt and emulsifier aqueous solution into a colloid mill for colloid milling to obtain emulsified asphalt. The performance of the obtained product was tested according to the standard, and the results are shown in Table 1.

[0033] The test performance result of the product obtained in embodiment 3 of table 1

[0034]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com