Preparation of an ultra-efficient carbon fiber electromagnetic shielding paper

A technology of electromagnetic shielding and effective carbon fiber, which is applied in the direction of magnetic field/electric field shielding, synthetic cellulose/non-cellulose material pulp/paper, non-fiber pulp addition, etc., can solve electromagnetic shielding efficiency, poor mechanical strength and heat resistance, and can not Meet the application requirements of carbon fiber electromagnetic shielding paper, the coating on the surface of the fiber is easy to crack and other problems, and achieve the effect of good messy effect, good electrical conductivity and low reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

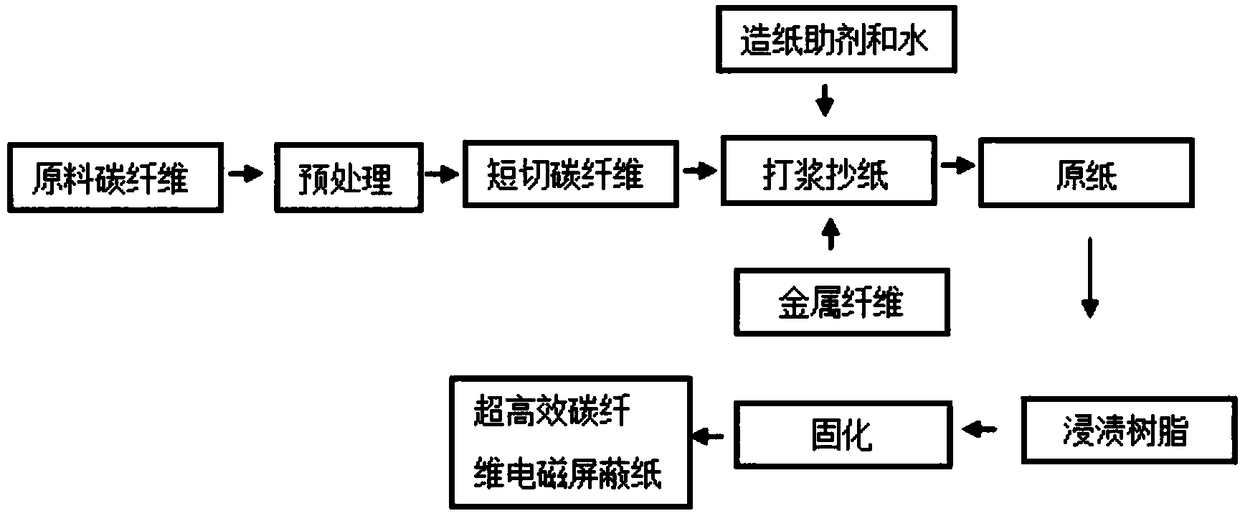

[0034] A preparation of ultra-efficient carbon fiber electromagnetic shielding paper, comprising the following steps:

[0035](1) Activation: pretreat the carbon fibers in 2mol / L NaOH for 2 hours, and use ultrasonic-assisted treatment; the ultrasonic treatment conditions are as follows: temperature is 40°C, ultrasonic frequency is 50kHz, and time is 30min; the treated carbon fibers are taken out and used to Wash with deionized water until neutral, remove the organic coating on the carbon fiber surface, dry and set aside;

[0036] (2) Compounding and additive addition: mix the carbon fiber treated in step (1) with stainless steel fiber, the mixed ingredients are by weight, carbon fiber: stainless steel fiber is 7:3; add the fiber slurry mass to the mixed slurry 0.12% APAM, 1% PVA in fiber slurry mass, stir for 30s;

[0037] (3) wet forming: a certain amount of slurry concentration obtained in step (2) is taken to be 0.09% and carried out in a sheet machine for wet forming, deh...

Embodiment 2

[0040] A preparation of ultra-efficient carbon fiber electromagnetic shielding paper, comprising the following steps:

[0041] (1) Activation: pretreat the carbon fibers in 1mol / L NaOH for 4 hours, and use ultrasonic-assisted treatment; the ultrasonic treatment conditions are as follows: the temperature is 60°C, the ultrasonic frequency is 100kHz, and the time is 10min; the treated carbon fibers are taken out and used to Wash with deionized water until neutral, remove the organic coating on the carbon fiber surface, dry and set aside;

[0042] (2) Compounding and additive addition: mix the carbon fiber treated in step (1) with stainless steel fiber, the mixed ingredients are by weight, carbon fiber: stainless steel fiber is 7:3; add the fiber slurry mass to the mixed slurry 0.5% APAM, 2% PVA of fiber slurry mass, stir for 30s;

[0043] (3) wet forming: a certain amount of slurry concentration obtained in step (2) is taken to be 0.09% and carried out in a sheet machine for wet...

Embodiment 3

[0046] A preparation of ultra-efficient carbon fiber electromagnetic shielding paper, comprising the following steps:

[0047] (1) Activation: pretreat the carbon fibers in 3mol / L NaOH for 1 hour, and use ultrasonic-assisted treatment; the conditions of ultrasonic treatment are as follows: the temperature is 20°C, the ultrasonic frequency is 20kHz, and the time is 60min; the treated carbon fibers are taken out and used to Wash with deionized water until neutral, remove the organic coating on the carbon fiber surface, dry and set aside;

[0048] (2) Compounding and additive addition: mix the carbon fiber treated in step (1) with stainless steel fiber, the mixed ingredients are by weight, carbon fiber: stainless steel fiber is 7:3; add the fiber slurry mass to the mixed slurry 0.6% APAM, 3% PVA of fiber slurry mass, stirring for 30s;

[0049] (3) wet forming: a certain amount of slurry concentration obtained in step (2) is taken to be 0.09% and carried out in a sheet machine fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com