Method for preparing nitrogen doped carbon loaded cobaltosic oxide electrode material

A technology of tricobalt tetroxide and electrode materials, which is applied to battery electrodes, hybrid capacitor electrodes, circuits, etc., can solve problems that do not involve the regulation of carbon matrix components, and achieve good dispersion, simple process, and small particles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

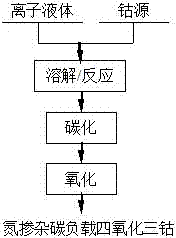

[0013] The invention is a preparation method of a nitrogen-doped carbon-supported cobalt tetroxide electrode material, the steps of which are as follows:

[0014] (1) Mixing: Weigh the carbon source and cobalt source in a mortar according to the mass ratio of 10:1-100:1, grind and mix to obtain a viscous liquid mixture;

[0015] (2) Carbonization: put the above liquid mixture into a tube furnace, raise the temperature to 100-400°C for 10-60min in an argon atmosphere, then raise the temperature to 600-1600°C for 60-360min, cool to room temperature, and obtain the precursor body;

[0016] (3) Oxidation: The above precursor is heated to 200-700°C in an air atmosphere, kept for 20-120min and then cooled to room temperature to prepare nitrogen-doped carbon-supported cobalt tetroxide electrode material.

[0017] The carbon source described in the above preparation method is an ionic liquid, specifically 1-butyl-3-methylimidazolium tetrafluoroborate, or 1-butyl-3-methylimidazolium d...

Embodiment 1

[0021] Put 20g of 1-butyl-3-methylimidazolium tetrafluoroborate and 1g of cobalt acetate in a mortar, grind and mix them evenly, put them into a crucible, and heat them to 100°C for 30min in a tube furnace under the protection of argon. Then raise the temperature to 700°C for 120 minutes, cool to room temperature; then raise the temperature to 600°C for 30 minutes in an air atmosphere, and cool to room temperature to obtain a nitrogen-doped carbon-supported tricobalt tetroxide electrode material. The electrochemical performance test of the obtained nitrogen-doped carbon-supported cobalt tetroxide electrode material adopts CR2025 button cells, and the prepared nitrogen-doped carbon-supported cobalt tetroxide active material is mixed with the conductive agent acetylene black and the binder PVDF (polyvinylidene fluoride). 8:1:1 mix evenly, add appropriate amount of NMP (N-methylpyrrolidone) and grind evenly in an agate mortar to form a viscous jelly-like mixture, then evenly sprea...

Embodiment 2

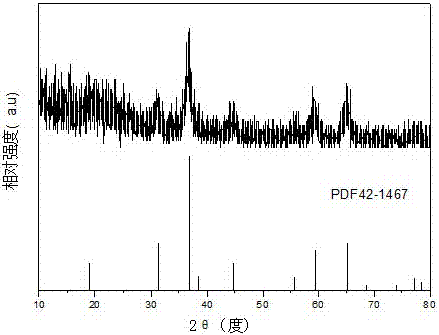

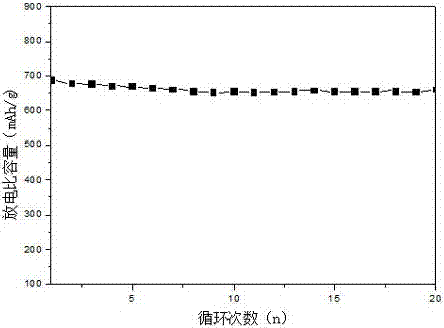

[0023] Put 20g of 1-butyl-3-methylimidazolium dinitrile ammonium salt and 1g of cobalt acetate in a mortar, grind and mix them evenly, put them into a crucible, heat them in a tube furnace to 100°C for 30min under the protection of argon, and then Raise the temperature to 900°C for 120 minutes, cool to room temperature; then raise the temperature to 450°C for 45 minutes in an air atmosphere, and cool to room temperature to obtain a nitrogen-doped carbon-supported tricobalt tetroxide electrode material (XRD see attached figure 2 ). According to the method of Example 1, the battery was assembled and tested. Under the condition of charge and discharge rate of 0.1C, the initial discharge specific capacity of the material was 904.2mAh / g, and the capacity remained at 679.3 mAh / g after 20 cycles (see attached image 3 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com