A kind of cooking utensil and preparation method thereof

A manufacturing method and technology for cooking utensils, which are used in kitchen utensils, household utensils, special materials for cooking utensils, etc., can solve the problems of less minerals and less dissolved oxygen, and achieve increased corrosion resistance, not easy to fall off, and increased wear resistance. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

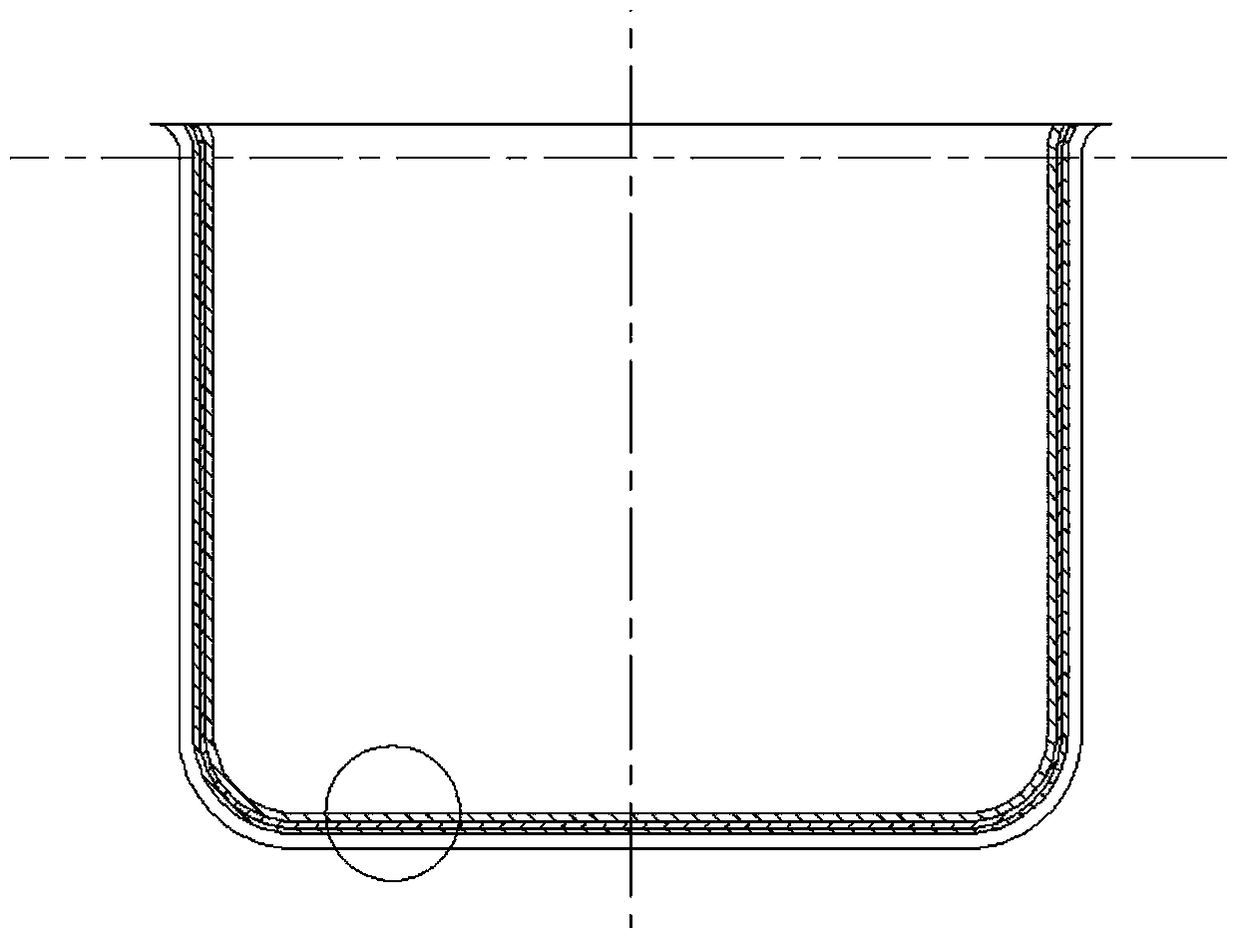

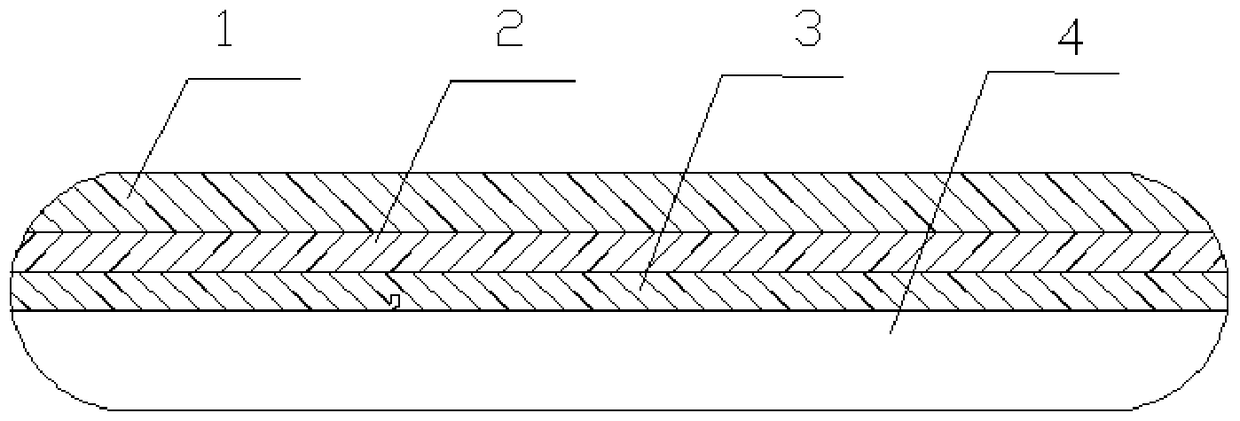

[0052] The cooker provided by this embodiment, such as figure 1 , 2 As shown, the cooking utensil base 4 is included, the inner surface of the cooking utensil base is attached with an intermediate bonding layer 3, and the surface of the intermediate bonding layer 3 is attached with a non-stick coating.

[0053] Wherein, the intermediate bonding layer can be attached to the inner surface of the cookware base by an anodic oxidation process, but is preferably attached to the inner surface of the cooker base by a thermal spraying process or a hard anodic oxidation process.

[0054] Wherein, the material of the cooker base is aluminum alloy, stainless steel or ceramic material; the material of the intermediate bonding layer is alumina, zirconia or titanium oxide; the thickness of the intermediate bonding layer attached by anodic oxidation process is 2 μm to 5 μm, The thickness range of the intermediate bonding layer attached by thermal spraying process or hard anodizing process i...

Embodiment 2

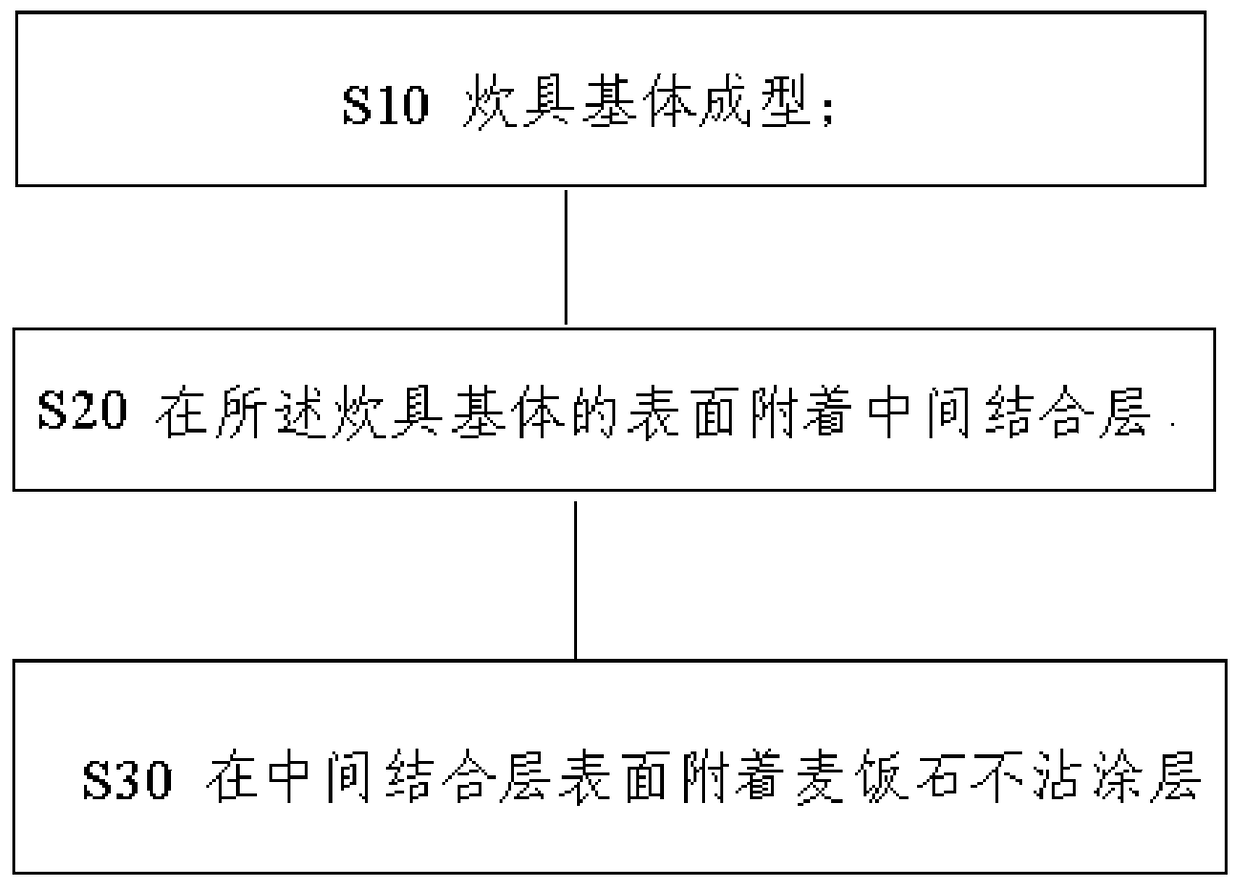

[0078] This embodiment provides a method for manufacturing a cooker, comprising the steps of:

[0079] S10 cooking utensil matrix forming;

[0080] S20 attaching an intermediate bonding layer on the surface of the cookware base through a thermal spraying process;

[0081] Among them, before spraying, it is necessary to carry out a series of pretreatments on the cookware substrate to improve the bonding force between the coating and the cookware substrate. Degreasing treatment Clean the grease on the surface of the substrate, clean the dirt and dust on the surface of the metal substrate; use 60-100# alumina sand to evenly sandblast the substrate to make the roughness Ra of the substrate reach 2-3.5μm.

[0082] Described thermal spraying process (also referred to as plasma spraying process) parameter condition is: spraying distance is 120mm; Spraying power is 35Kw; Main gas is Ar, and gas flow rate is 46L / min; Secondary gas is H2, and gas flow rate is 4.3L / min; the powder fee...

Embodiment 3

[0099] Compared with adopting the method described in Example 2 to prepare the cooker, the difference is: the electrostatic spray gun mode is used to prepare the undercoat and the top coat; wherein, the non-stick resin of the undercoat and the top coat is PFA (soluble polytetrafluoroethylene vinyl fluoride).

[0100] The method of electrostatic spraying is adopted, and the auxiliary material is compressed air, which requires clean and dry, oil-free and water-free [moisture content less than 1.3g / m 3 , oil content less than 1.0×10 -5 % (mass fraction)], the specific process parameters of its spraying are as follows: electrostatic high voltage: 20-50kV; electrostatic current: 10-20μA; flow rate pressure: 0.30-0.55MPa; atomization pressure: 0.30-0.45MPa; MPa; fluidization pressure of powder supply barrel: 0.04-0.10MPa; distance from spray gun mouth to workpiece: 150-300mm; conveyor chain speed: 4.5-5.5m / min; thickness of electrostatic spraying is controlled at 30-80μm.

[0101]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com