Honeycomb ceramic-based fine-particle-size NaA molecular sieve block adsorbent and in-situ synthesis method and application

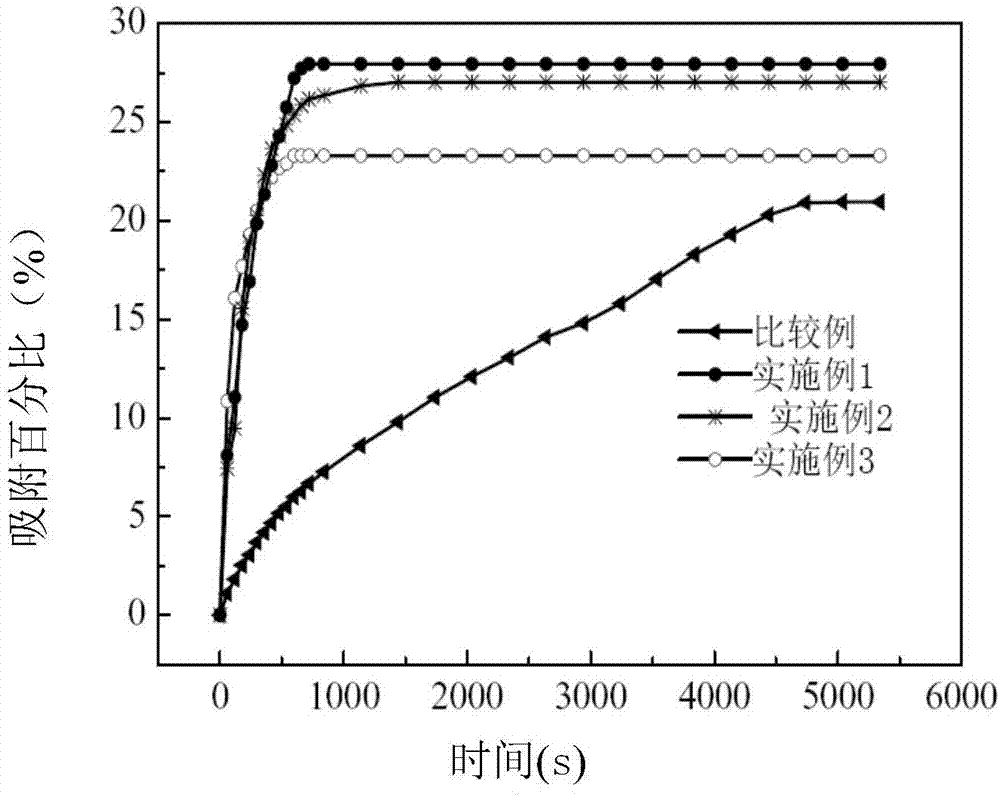

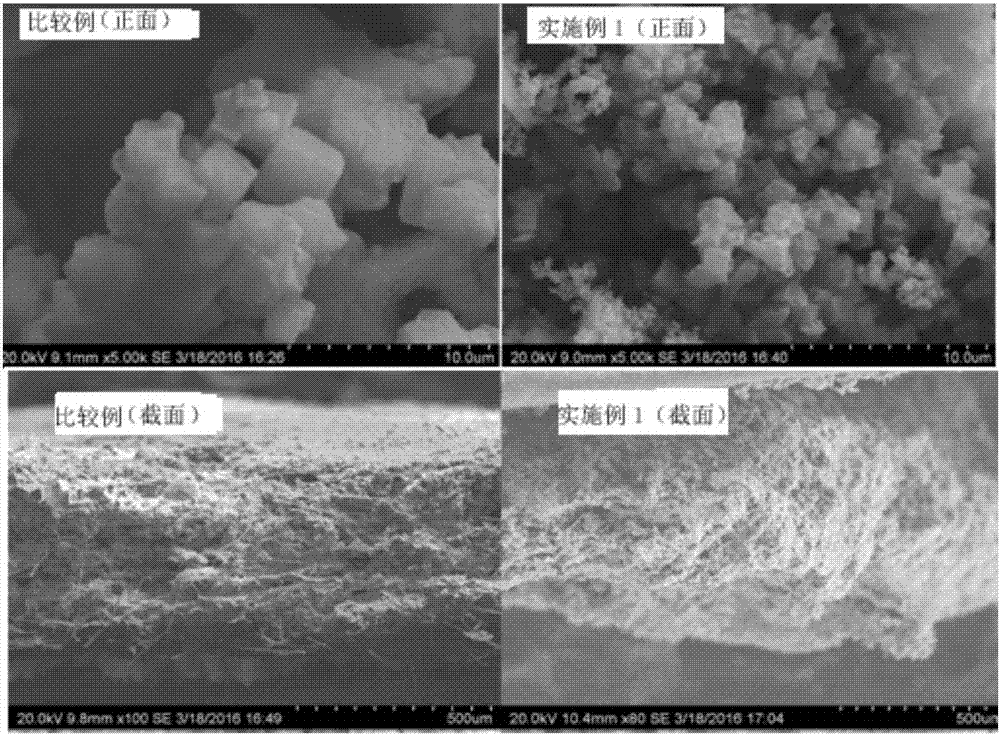

A technology of honeycomb ceramics and in-situ synthesis, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problem of low early adsorption rate and equilibrium adsorption capacity, affecting service life and adsorption performance, and large particle size of industrial molecular sieves and other problems, to achieve the effect of large early adsorption rate, small grain size, and weakened powder drop phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] An in-situ synthesis method of a honeycomb ceramic-based fine-grained NaA molecular sieve block adsorbent, comprising the following steps:

[0051] (1) Preparation of the honeycomb ceramic body: the weight is 35g / m 2 Ceramic fiber paper (comprising base paper, surface paper) is dip-coated in the silica sol of 20wt% until fully wetted, obtains the ceramic fiber paper that dips and is coated with silica sol; The ceramic fiber paper is made into a honeycomb ceramic-based cylindrical body (H×D=6×4cm) by hot pressing and wrapping; at room temperature, the honeycomb ceramic-based cylindrical body is immersed in a magnesium chloride solution with a mass fraction of 4% After being fully soaked, take it out and dry it, transfer it to an oven for 12 hours at 120°C, and finally place it in a muffle furnace for sintering at 550°C for 6 hours to obtain a honeycomb ceramic green body;

[0052] (2) Dip coating of seed crystals: suspend the honeycomb ceramic embryo body in a 500mL vac...

Embodiment 2

[0057] An in-situ synthesis method of a honeycomb ceramic-based fine-grained NaA molecular sieve block adsorbent, comprising the following steps:

[0058] (1) Preparation of the honeycomb ceramic body: the weight is 35g / m 2 The ceramic fiber paper (comprising base paper, surface paper) dip-coated in the silica sol that massfraction is 20% is until fully wetted, obtains the ceramic fiber paper that dips and is coated with silica sol; The ceramic fiber paper of silica sol is made into a honeycomb ceramic-based cylindrical body (H×D=6×4cm) by hot pressing and wrapping; at room temperature, the honeycomb ceramic-based cylindrical body is immersed in a mass fraction of 6% After being completely soaked in the magnesium chloride solution, take it out and dry it, transfer it to an oven for 12 hours at 120°C, and finally place it in a muffle furnace for sintering at 450°C for 8 hours to obtain a honeycomb ceramic green body;

[0059] (2) Dip coating of seed crystals: suspend the honey...

Embodiment 3

[0064] An in-situ synthesis method of a honeycomb ceramic-based fine-grained NaA molecular sieve block adsorbent, comprising the following steps:

[0065] (1) Preparation of the honeycomb ceramic body: the weight is 35g / m 2 The ceramic fiber paper (comprising base paper, surface paper) dip-coated in the silica sol that massfraction is 20% is until fully wetted, obtains the ceramic fiber paper that dips and is coated with silica sol; The ceramic fiber paper of silica sol is made into a honeycomb ceramic-based cylindrical body (H×D=6×4cm) by hot pressing and wrapping; at room temperature, the honeycomb ceramic-based cylindrical body is immersed in a mass fraction of 2% After being completely soaked in the magnesium chloride solution, take it out and dry it, transfer it to an oven for 12 hours at 120°C, and finally place it in a muffle furnace for sintering at 500°C for 7 hours to obtain a honeycomb ceramic green body;

[0066] (2) Dip coating of seed crystals: suspend the honey...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com