Anti-aging and migration resistant plasticized polyvinyl chloride material, preparation method and application thereof

A polyvinyl chloride, migration-resistant technology, used in plastic/resin/wax insulators, organic insulators, etc., can solve the problems of plasticizing effect, flexibility, etc., to improve heat resistance and UV resistance, small size, The effect of improving toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

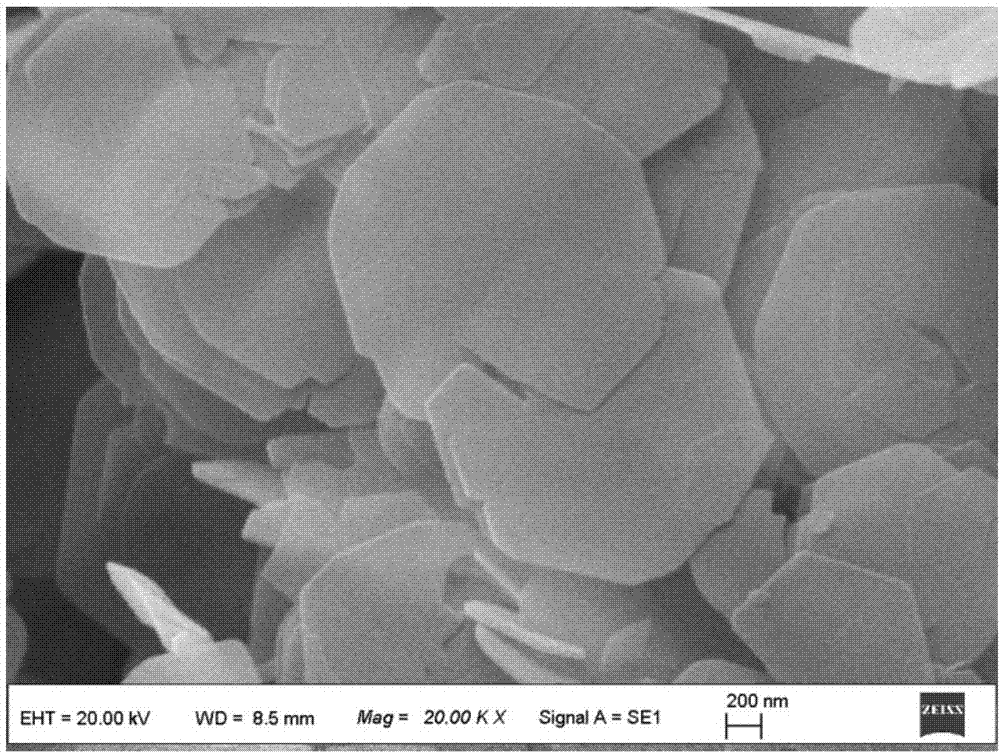

[0042] (1) Weigh 0.08mol of nickel chloride, 0.12mol of zinc chloride, 0.1mol of lanthanum chloride and 0.3225mol of urea and dissolve them in deionized water, then sonicate for 30min, transfer them to the autoclave, and then put React in a muffle furnace at 180°C for 12 hours. After the reaction, filter and wash to obtain LDHs powder.

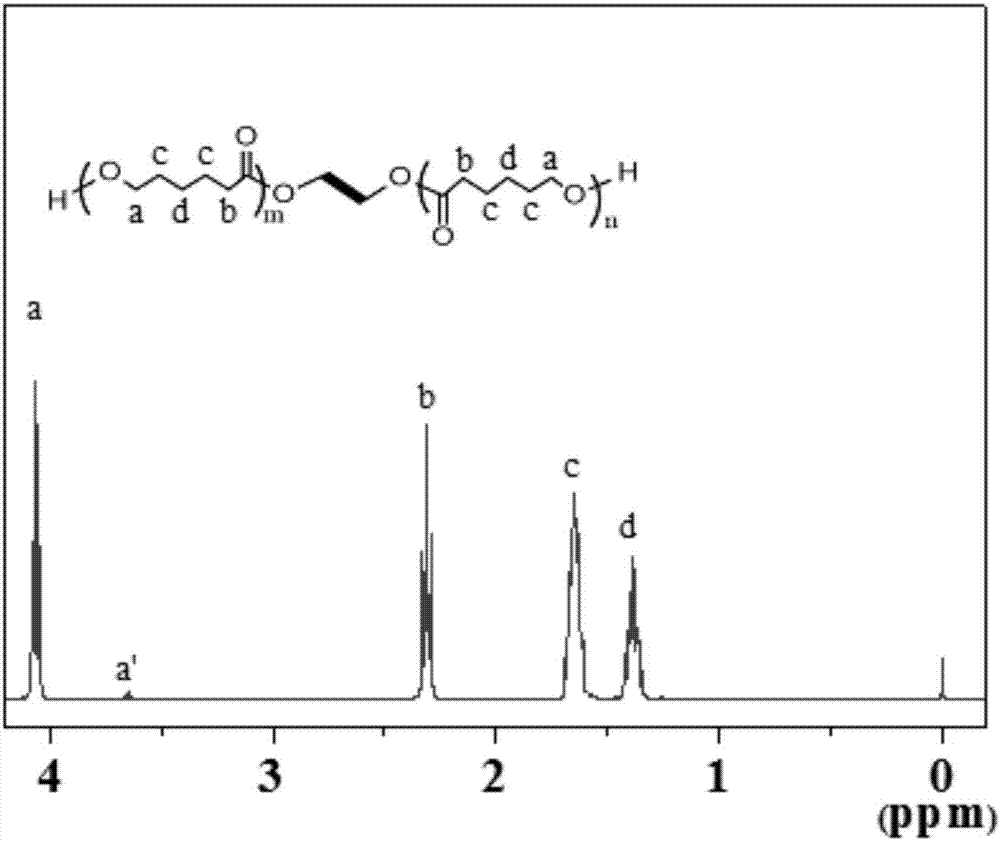

[0043] (2) Weigh 4g of LDHs and 30g of ε-CL into a three-neck flask, ultrasonicate for 30min, heat up to 110°C, add catalyst stannous octoate, N 2 React under protection for 24 hours. After the reaction is over, dissolve the viscous polymer in dichloromethane, filter and wash to remove impurities, precipitate in glacial hexane, wash to remove unreacted monomers, and vacuum at 40°C. Dry for 24h to get LDHs-g-PCL.

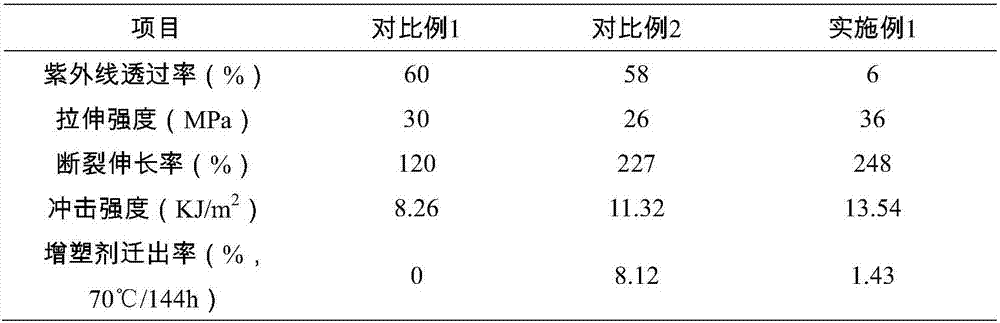

[0044] (3) Melt blending LDHs-g-PCL and polyvinyl chloride in a torque rheometer for 15 min at a mass ratio of 20:80 to obtain modified polyvinyl chloride, wherein LDHs-g-PCL and polyvinyl chloride The mass is 30g. Set the tempera...

Embodiment 2

[0047] (1) Weigh 0.19 mol of zinc chloride, 0.1 mol of cerium chloride and 0.3045 mol of urea and dissolve them in deionized water, then sonicate for 30 minutes, transfer them to an autoclave, and then put them into a muffle furnace at 120°C After the reaction was completed for 36 hours, the LDHs powder was obtained by filtering and washing.

[0048] (2) Weigh 0.5g of LDHs and 49.5g of ε-CL into a three-neck flask, ultrasonicate for 20min, heat up to 100°C, add catalyst stannous octoate, N 2 React under protection for 20 hours. After the reaction is over, dissolve the viscous polymer in dichloromethane, filter and wash to remove impurities, precipitate in glacial hexane, wash to remove unreacted monomers, and vacuum at 30°C. Dry for 30h to get LDHs-g-PCL.

[0049] (3) LDHs-g-PCL and polyvinyl chloride were melt-blended in a torque rheometer for 45 minutes at a mass ratio of 5:95 to obtain modified polyvinyl chloride, wherein LDHs-g-PCL and polyvinyl chloride were combined Th...

Embodiment 3

[0052] (1) Weigh 0.2mol of nickel chloride, 0.21mol of cobalt chloride, 0.05mol of lanthanum chloride, 0.05mol of cerium chloride and 0.5355mol of urea and dissolve them in deionized water, then sonicate for 50min and transfer to high pressure The reaction kettle was then put into a muffle furnace at 180° C. to react for 6 hours. After the reaction was completed, it was filtered and washed to obtain LDHs powder.

[0053] (2) Weigh 6g of LDHs and 34g of ε-CL into a three-neck flask, ultrasonicate for 50min, heat up to 140°C, add catalyst stannous octoate, N 2 React under protection for 30 hours. After the reaction, dissolve the viscous polymer in dichloromethane, filter and wash to remove impurities, precipitate in glacial hexane, wash to remove unreacted monomers, and vacuum at 30°C. Dry for 30h to get LDHs-g-PCL.

[0054] (3) Melt blend LDHs-g-PCL and polyvinyl chloride at a mass ratio of 50:50 in a torque rheometer for 10 min to obtain modified polyvinyl chloride, wherein L...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com