Pure metal or alloy products micro hole machining system

A micro-hole processing, pure metal technology, applied in metal processing equipment, manufacturing tools, welding equipment, etc., can solve the problems of low utilization rate of ultra-short laser pulse energy, insufficient depth of limit, thick thickness of recast layer, etc. Conducive to the effect of caliber size, deepening the depth of micropores, and reducing the possibility of cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

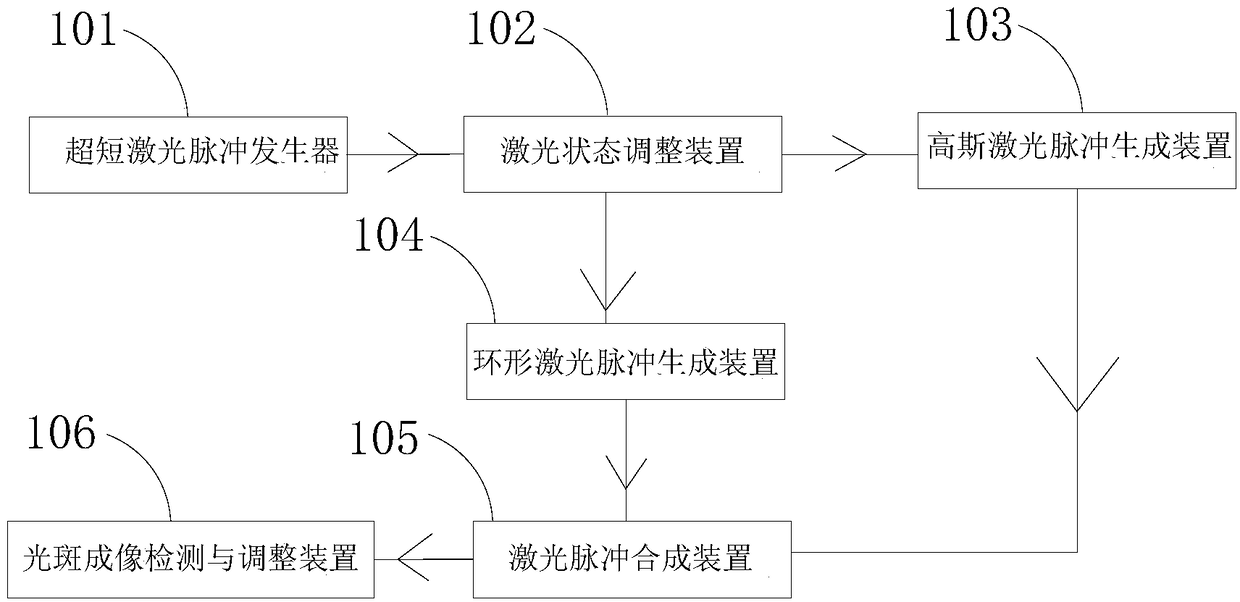

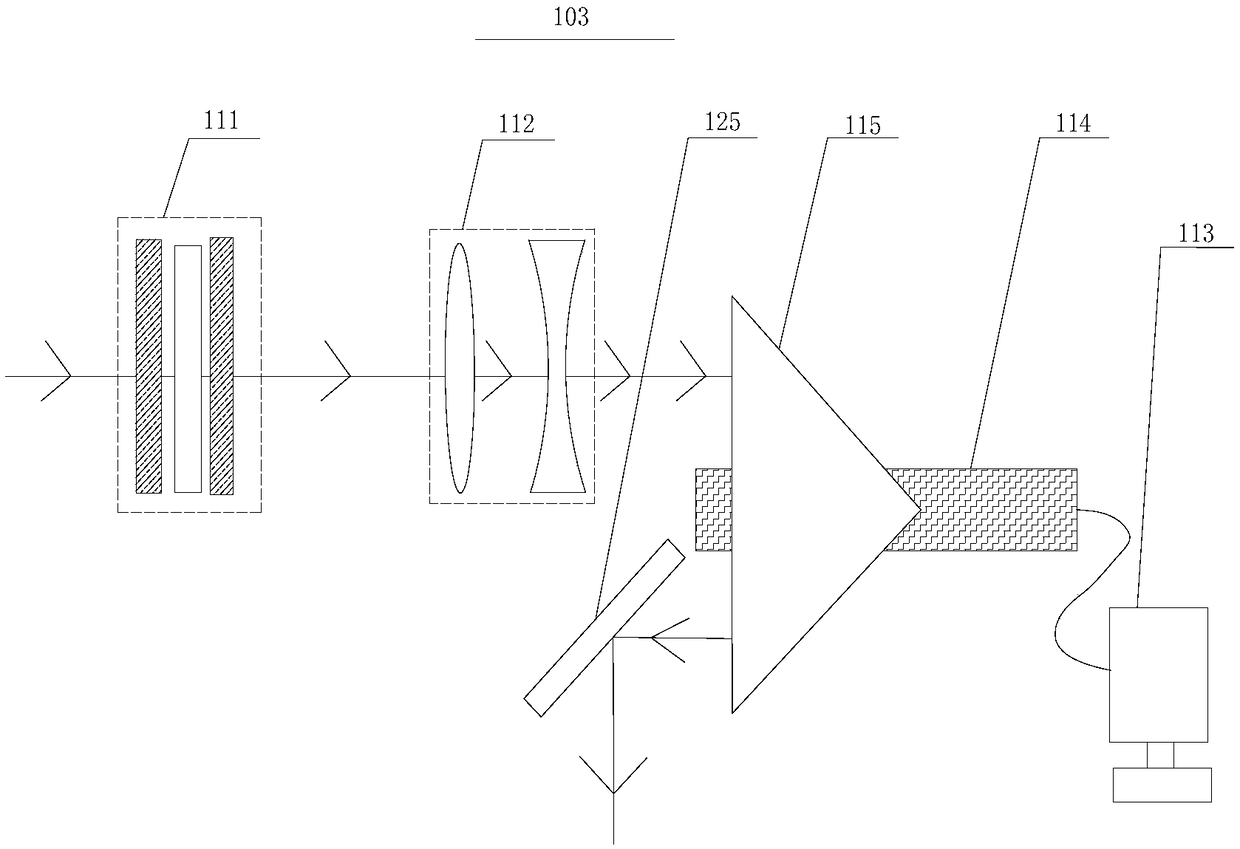

[0058] see figure 1 , an embodiment of the present invention is a pure metal or alloy product microhole processing system, the pure metal or alloy product processing system includes an ultrashort laser pulse generator 101, a laser state adjustment device 102, a Gaussian laser pulse generation device 103, a ring laser pulse generation device The device 104 and the laser pulse synthesis device 105.

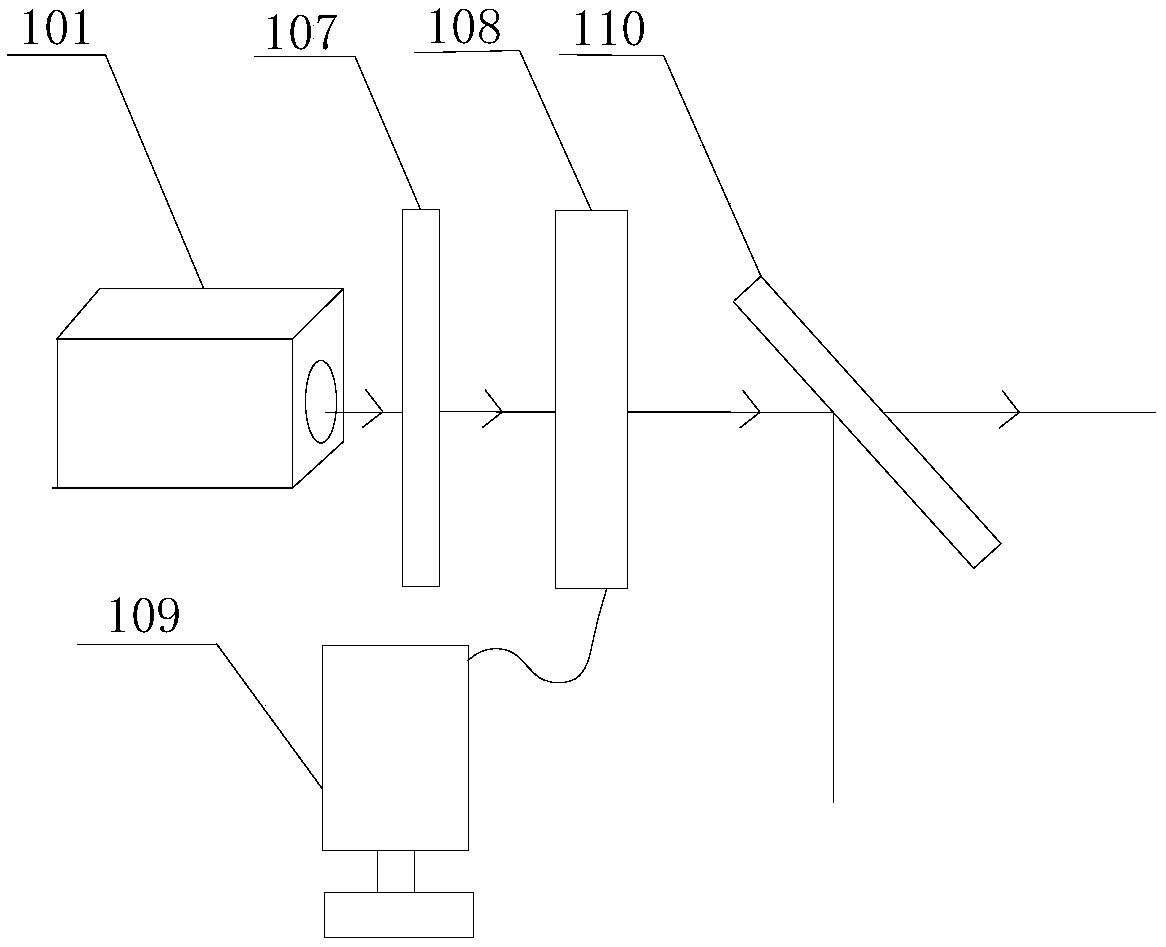

[0059] The ultrashort laser pulse generator 101 is used to generate ultrashort laser pulses, and output the ultrashort laser pulses to the laser state adjustment device 102 .

[0060] Wherein, in this embodiment, the ultrashort laser pulse is a femtosecond ultrashort laser pulse, and the parameters of the femtosecond ultrashort laser pulse are: center wavelength 800nm, laser linewidth 40nm, laser pulse width 120fs, repetition frequency 1kHz, output The power is 1W, the power jitter is less than 5%, and the laser polarization direction is the horizontal polarization state.

[0061]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com