Preparation method of paraffin inhibitor for oil wells

A wax inhibitor, oil well technology, applied in chemical instruments and methods, mechanical equipment, drilling compositions, etc., can solve problems such as poor viscosity reduction effect and unsatisfactory effect, achieve good wax inhibitor effect, and inhibit paraffin wax. The effect of depositing, improving fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

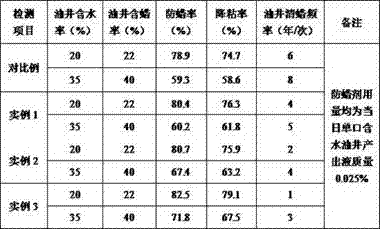

Examples

example 1

[0019] First weigh 1kg of papermaking black liquor and filter to obtain the filtrate, add the filtrate to the beaker, then add 60mL of sulfuric acid solution with a mass fraction of 15% in the beaker, and move the beaker into a digital speed measuring constant temperature magnetic stirrer. 110°C and a rotating speed of 300r / min, stir and react at a constant temperature for 2 hours, then filter to obtain a filter residue. Take 40g of the filter residue and place it in a beaker filled with 200mL of 5% sodium sulfite solution, and place the beaker in an oil bath. Control the temperature of the oil bath at 140°C, heat and stir the reaction for 3 hours. After the reaction is completed, place the material in the beaker in a rotary evaporator, and concentrate it to dryness by rotary evaporation to obtain a dried product. Then take 20 g of the dried product and add it to a container filled with 100 mL of water. and place the three-necked flask in a water bath, control the temperature o...

example 2

[0021]First take by weighing 1kg of papermaking black liquor and filter to obtain the filtrate, add the filtrate to the beaker, then add 70mL of sulfuric acid solution with a mass fraction of 15% in the beaker, and move the beaker into a digital speed measuring constant temperature magnetic stirrer, at a temperature of Under the conditions of 115°C and a rotating speed of 350r / min, stir and react at a constant temperature for 2 hours and then filter to obtain a filter residue. Take 45g of the filter residue and place it in a beaker containing 250mL of a 5% sodium sulfite solution, and place the beaker in an oil bath. Control the temperature of the oil bath at 145°C, heat and stir the reaction for 3 hours. After the reaction is completed, place the material in the beaker in a rotary evaporator, and concentrate it to dryness by rotary evaporation to obtain a dry product. Then take 25g of the dry product and add it to a container filled with 150mL of water. and place the three-nec...

example 3

[0023] First take by weighing 2kg of papermaking black liquor and filter to obtain the filtrate, add the filtrate to the beaker, then add 80 mL of sulfuric acid solution with a mass fraction of 15% in the beaker, and move the beaker into a digital speed measuring constant temperature magnetic stirrer, at a temperature of Under the conditions of 120°C and a rotating speed of 400r / min, stir and react at a constant temperature for 3 hours and then filter to obtain a filter residue. Take 50g of the filter residue and place it in a beaker filled with 300mL of 5% sodium sulfite solution, and place the beaker in an oil bath. Control the temperature of the oil bath at 150°C, keep warm and stir for 4 hours. After the reaction is over, put the material in the beaker in a rotary evaporator, and concentrate it to dryness by rotary evaporation to obtain a dry product. Then take 30g of the dry product and 0.5g of ferric sulfate and add into a three-necked flask filled with 200mL of water, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com