Superfine mulberry leaf powder and preparation method thereof

A technology of mulberry leaf powder and mulberry leaves, which is applied in the direction of medical formula, food ultrasonic treatment, medical preparations containing active ingredients, etc., can solve the problems of insufficient absorption of nutrients and biologically active substances, destruction of nutrients and chlorophyll, and It does not meet the requirements of food additives and other issues, and achieves the effect of maintaining its own value, excellent activity and function, and avoiding nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

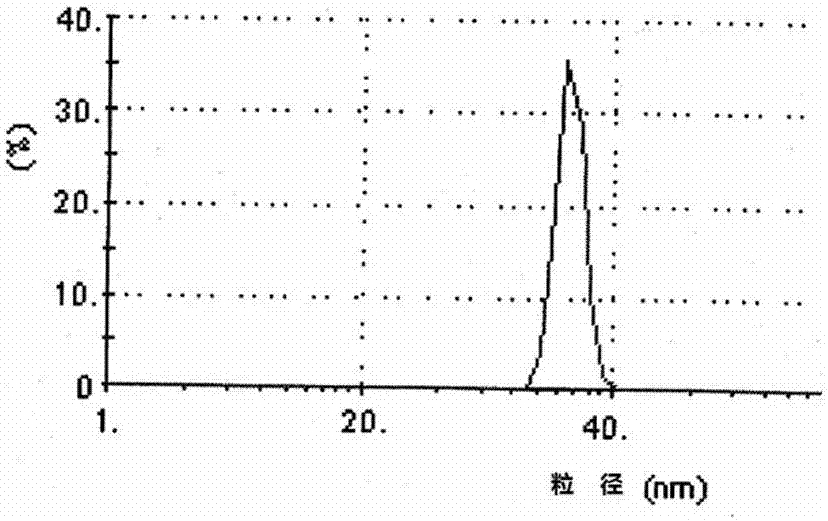

Image

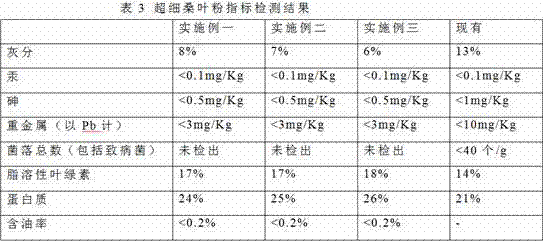

Examples

Embodiment 1

[0066] Embodiment one A kind of preparation method of superfine mulberry leaf powder, comprises the steps:

[0067] (1) Remove impurities on the surface of mulberry leaves to obtain impurity-removed mulberry leaves;

[0068] (2) Soak the mulberry leaves in pure water for 30 minutes with a bath ratio of 30:1, and then perform wall-breaking treatment; then undergo ultrasonic treatment to obtain a mulberry leaf solution; the wall-breaking treatment is carried out at a speed of 65,000 rpm Wall-breaking treatment, the time is 45 minutes; the power of the ultrasonic treatment is 1000W, the frequency is 30KHz, and the time is 10 minutes;

[0069] (3) Add AE202 cellulase to the mulberry leaf solution, then add 0.8% olive oil in the volume of the mulberry leaf solution, and obtain an enzymatic hydrolysis solution after enzymatic hydrolysis;

[0070] The enzyme dosage is 600 activity units / g mulberry leaf powder, the enzymolysis temperature is 40°C, the enzymolysis time is 2.5 hours, a...

Embodiment 2

[0075] Embodiment two A kind of preparation method of superfine mulberry leaf powder, comprises the steps:

[0076] (1) Remove impurities on the surface of mulberry leaves to obtain impurity-removed mulberry leaves;

[0077] (2) Soak the mulberry leaves in pure water for at least 30 minutes with a bath ratio of 50:1, and then perform wall-breaking treatment; then undergo ultrasonic treatment to obtain a mulberry leaf solution; the wall-breaking treatment is performed at a speed of 70,000 rpm Carry out the wall-breaking treatment for 50 minutes; the power of the ultrasonic treatment is 1200W, the frequency is 50KHz, and the time is 15 minutes;

[0078] (3) Add AE202 cellulase to the mulberry leaf solution, then add 0.6% olive oil by volume of the mulberry leaf solution, and obtain an enzymatic hydrolysis solution after enzymatic hydrolysis;

[0079] The enzyme dosage is 800 activity units / g mulberry leaf powder, the enzymolysis temperature is 40°C, the enzymolysis time is 2 ho...

Embodiment 3

[0084] Embodiment three A kind of preparation method of superfine mulberry leaf powder, comprises the steps:

[0085] (1) Remove impurities on the surface of mulberry leaves to obtain impurity-removed mulberry leaves;

[0086] (2) Soak the mulberry leaves in pure water for at least 30 minutes, with a bath ratio of 50:1, and then perform wall-breaking treatment; then undergo ultrasonic treatment to obtain a mulberry leaf solution; the wall-breaking treatment is performed at a speed of 68,000 rpm Carry out the wall-breaking treatment for 45 minutes; the power of the ultrasonic treatment is 1100W, the frequency is 40KHz, and the time is 15 minutes;

[0087] (3) Add AE202 cellulase to the mulberry leaf solution, then add 0.7% olive oil in the volume of the mulberry leaf solution, and obtain an enzymatic hydrolysis solution after enzymolysis;

[0088] The enzyme dosage is 700 activity units / g mulberry leaf powder, the enzymolysis temperature is 40°C, the enzymolysis time is 2.5 ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com