Injectable bone repair material and preparation method thereof

A bone repair and dopamine technology, which is applied in the field of biomedical materials and biomedical engineering, can solve the problems of poor yield strength and impact resistance, unsuitable use, low shear and tensile strength, etc., and achieves enhanced mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

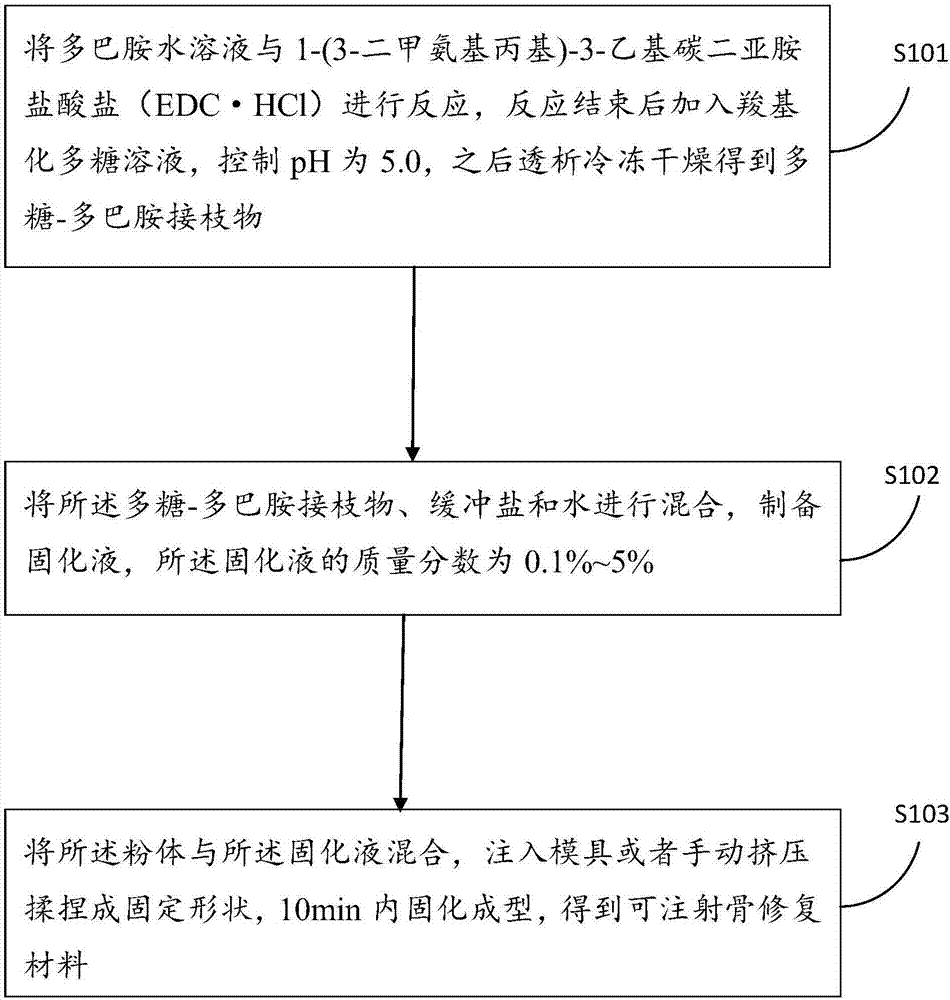

[0025] The present invention also provides a preparation method of the above-mentioned injectable bone repair material, such as figure 1 shown, including the following steps:

[0026] S101: React dopamine aqueous solution with 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride (EDC·HCl), add carboxylated polysaccharide solution after the reaction, and control the pH to 5.0 , followed by dialysis and freeze-drying to obtain polysaccharide-dopamine grafts;

[0027] S102: Mix the polysaccharide-dopamine graft, buffer salt, and water to prepare a solidified solution, where the mass fraction of the solidified solution is 0.1% to 5%;

[0028] S103: The powder is mixed with the solidification liquid, injected into a mold or manually extruded and kneaded into a fixed shape, and solidified within 10 minutes to obtain an injectable bone repair material.

[0029] The preparation method of the carboxylated polysaccharide in step S101 comprises: adding tetramethylpiperidinium ox...

Embodiment 1

[0037] Prepare 500 mL of 0.5% agarose solution, add 0.02 g of tetramethylpiperidine oxide (TEMPO) and 0.4 g of sodium bromide, adjust the pH to 5.0 with sodium hydroxide, and add 4 mL of 10% sodium hypochlorite after reacting for 1 hour. 1mol / L sodium hydroxide was used to adjust the pH to maintain at 10, and reacted for 4 hours. The polysaccharide material was precipitated by adding excess absolute ethanol, washed twice with ethanol and acetone, and then dried by rotary evaporation to obtain a powder material, which was dissolved in water and titrated with hydrochloric acid until the pH was 7.0. The dialysis bag was dialyzed for 3 days and then freeze-dried to obtain carboxylated agarose;

[0038] Prepare 5 mg / mL dopamine aqueous solution, add 1 mg / mL 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride (EDC·HCl) and react for a period of time at 4 degrees Celsius, After the reaction, add 3mg / mL carboxylated agarose solution, control the pH to 5.0, react at room tempe...

Embodiment 2

[0045] Prepare 400 mL of 1% dextran solution, add 0.01 g of tetramethylpiperidine oxide (TEMPO) and 0.35 g of sodium bromide, adjust the pH to 5.0 with sodium hydroxide and add 5 mL of 10% sodium hypochlorite after reacting for 1 hour. Adjust the pH with 1mol / L sodium hydroxide to maintain at 10, and react for 4 hours. The polysaccharide material was precipitated by adding excess absolute ethanol, washed twice with ethanol and acetone, and then dried by rotary evaporation to obtain a powder material, which was dissolved in water and titrated with hydrochloric acid until the pH was 7.0. The dialysis bag was dialyzed for 3 days and then freeze-dried to obtain carboxylated dextran;

[0046] Prepare 4 mg / mL dopamine aqueous solution, add 0.8 mg / mL 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride (EDC·HCl) and react for a period of time at 4 degrees Celsius After the reaction, add 5mg / mL carboxylated dextran solution, control the pH to 5.0, react at room temperature (us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Average tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com