Catalyst for production of isoprene by 1-butene

A technology of isoprene and catalyst is applied in the field of chemical raw material preparation to achieve the effects of improving catalytic activity, increasing loading rate and good selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

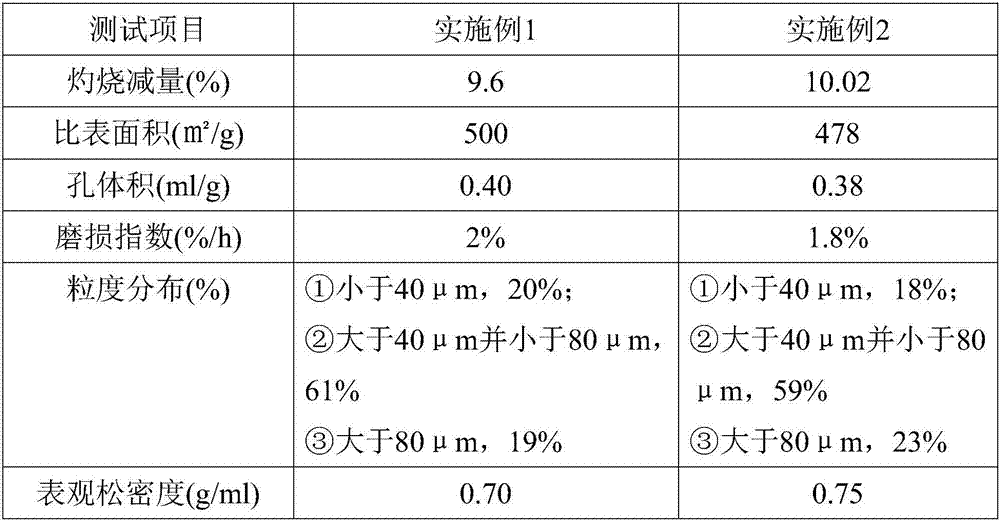

Examples

Embodiment 1

[0024] A catalyst for producing isoprene from 1-butene: comprising the steps of:

[0025] Catalyst for producing isoprene by 1-butene through alkenal synthesis method, with nano-activated carbon as carrier, 6 parts of SbF 5 / SiO 2 -ZrO 2 , ZrO 2 SO 4 、WO 3 ZrO 2 as the active ingredient, with 5 parts of bentonite as the auxiliary agent. Prepared by reverse drop precipitation method, dissolve the soluble matter of Sb, Zr and W in 200ml of 10% ethanol solution, stir for 30min, and configure a mixed solution with a concentration of 0.5mol / L, wherein the ratio of Sb, Zr and W is 0.05-0.05-0.1, under the condition of constant temperature stirring at 55°C, use a constant flow pump to add the mixed solution dropwise to 100ml 2mol / L precipitant solution, the constant flow pump speed is 60 rpm; stir for 0.6 hours, then Then add a certain concentration and a certain amount of NaOH solution, let it stand for precipitation overnight, and then use a vacuum pump to filter, wash, dry ...

Embodiment 2

[0030] A catalyst for producing isoprene from 1-butene: comprising the steps of:

[0031] 1-Butene is a catalyst for the production of isoprene by enaldehyde synthesis, with nano-activated carbon as the carrier, and 8 parts of SbF 5 / SiO 2 -ZrO 2 , ZrO 2 / ZrO 2 SO 4 、WO 3 ZrO 2 as the active ingredient, with 6 parts of bentonite as the auxiliary agent. Prepared by reverse drop precipitation method, dissolve the soluble matter of Sb, Zr and W in 200ml of 10% ethanol solution, stir for 45min, and configure a mixed solution with a concentration of 0.5mol / L, wherein the ratio of Sb, Zr and W is 0.05-0.05-0.1, under the condition of constant temperature stirring at 45°C, use a constant flow pump to add the mixed solution dropwise to 100ml 2mol / L precipitant solution, the speed of the constant flow pump is 40 rpm; stir for 0.5 hours, then Then add a certain concentration and a certain amount of NaOH solution, let it stand for precipitation overnight, and then filter it with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com