Particle size controllable manganous-manganic oxide nanoparticle material synthesized at constant temperature and preparation method thereof

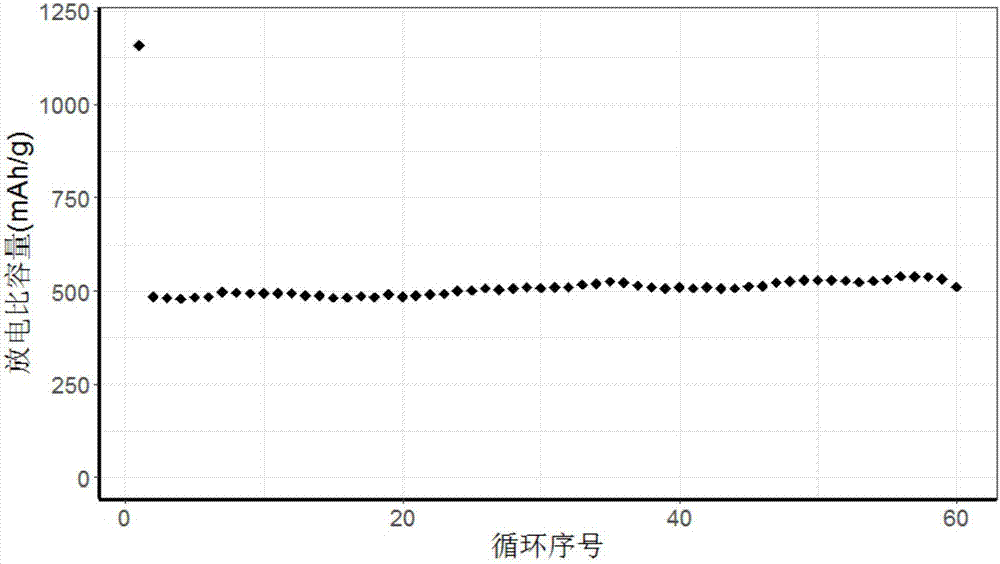

A technology for the synthesis of manganese tetroxide at room temperature, which is applied in the directions of manganese oxide/hydroxide, nanotechnology, etc., can solve the problems of high requirements and complicated processes, and achieves mild and efficient synthesis process, easy separation, and optimized cycle performance. and charge-discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

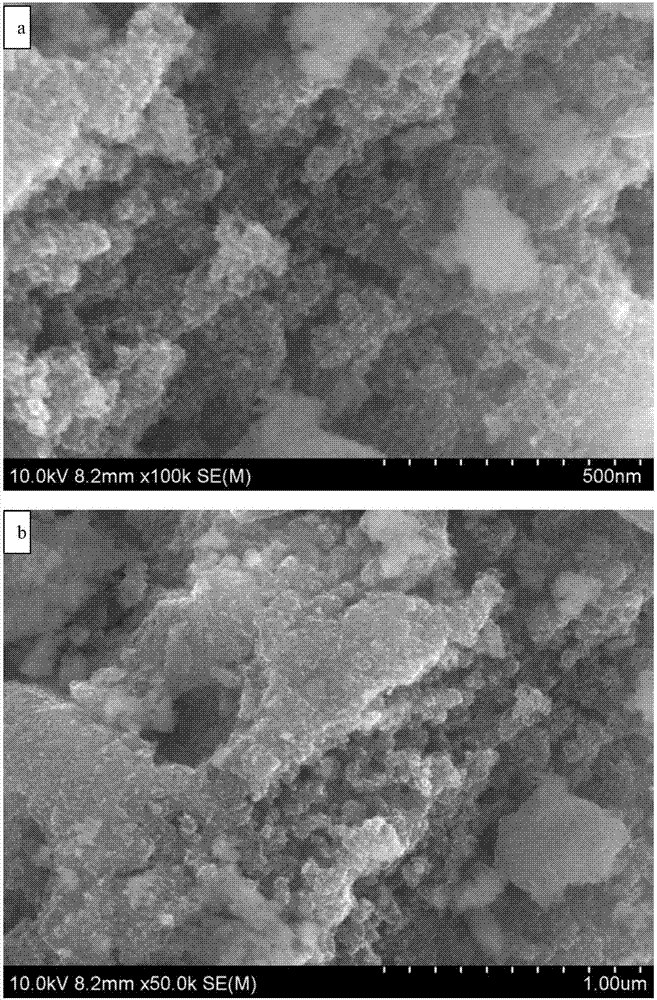

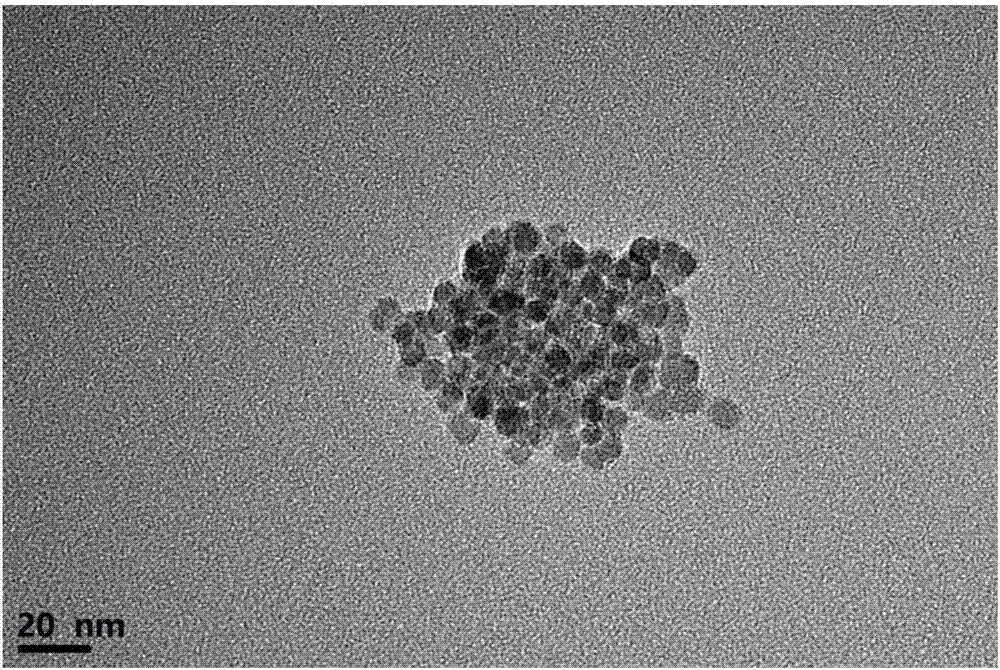

[0031] This embodiment provides a controllable particle size manganese tetraoxide nanoparticle material synthesized at room temperature and a preparation method thereof. between. Its preparation steps are as follows:

[0032] 1. Use an electronic balance to weigh 3g of manganese acetate and ultrasonically disperse it into 180ml of ethanol;

[0033] 2. Use a magnetic stirrer to continue stirring until the solution no longer changes color;

[0034] 3. Use an electronic balance to weigh 1.5g of potassium hydroxide and ultrasonically disperse it into 20ml of ethanol;

[0035] 4. Add the ethanol solution of potassium hydroxide dropwise in the ethanol solution of manganese acetate;

[0036] 5. Use a magnetic stirrer to continue stirring for 24 hours;

[0037] 6. The dispersion system was centrifuged, washed with ethanol for 3 times, and dried to obtain a brown manganese tetraoxide nanoparticle material synthesized at room temperature with a controllable particle size.

[0038] ...

Embodiment 2

[0044] This embodiment provides a controllable particle size manganese tetraoxide nanoparticle material synthesized at room temperature and a preparation method thereof. between. Its preparation steps are as follows:

[0045] 1. Use an electronic balance to weigh 3g of manganese acetate and ultrasonically disperse it into 180ml of ethanol;

[0046] 2. Use a magnetic stirrer to continue stirring until the solution no longer changes color;

[0047] 3. Use an electronic balance to weigh 1.5g of potassium hydroxide and ultrasonically disperse it into 20ml of ethanol;

[0048] 4. Add the ethanol solution of potassium hydroxide dropwise in the ethanol solution of manganese acetate;

[0049] 5. Use a magnetic stirrer to continue stirring for 12 hours;

[0050] 6. Drop 3g of pure water into the above system;

[0051] 7. Use a magnetic stirrer to continue stirring for 12 hours;

[0052] 8. Centrifuge the above dispersion system, wash with ethanol for 3 times, and dry to obtain br...

Embodiment 3

[0058] This embodiment provides a controllable particle size manganese tetraoxide nanoparticle material synthesized at room temperature and a preparation method thereof, wherein the controllable particle size synthetic manganese tetraoxide nanoparticle material has a particle size of 2-30 nm between. Its preparation steps are as follows:

[0059] 1. Use an electronic balance to weigh 3g of manganese acetate and ultrasonically disperse it into 180ml of ethanol;

[0060] 2. Use a magnetic stirrer to continue stirring until the solution no longer changes color;

[0061] 3. Use an electronic balance to weigh 1.5g of potassium hydroxide and ultrasonically disperse it into 20ml of ethanol;

[0062] 4. Add the ethanol solution of potassium hydroxide dropwise in the ethanol solution of manganese acetate;

[0063] 5. Use a magnetic stirrer to continue stirring for 12 hours;

[0064] 6. Drop 10g of pure water into the above system;

[0065] 7. Use a magnetic stirrer to continue sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com