Tetrafluoroethylene dispersion resin for manufacturing long fiber for base cloth and preparation method of tetrafluoroethylene dispersion resin

A tetrafluoroethylene, dispersing resin technology, applied in the direction of chemical characteristics of fibers, textiles and papermaking, one-component synthetic polymer rayon, etc. problems, to achieve the effect of low cost, high production efficiency and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

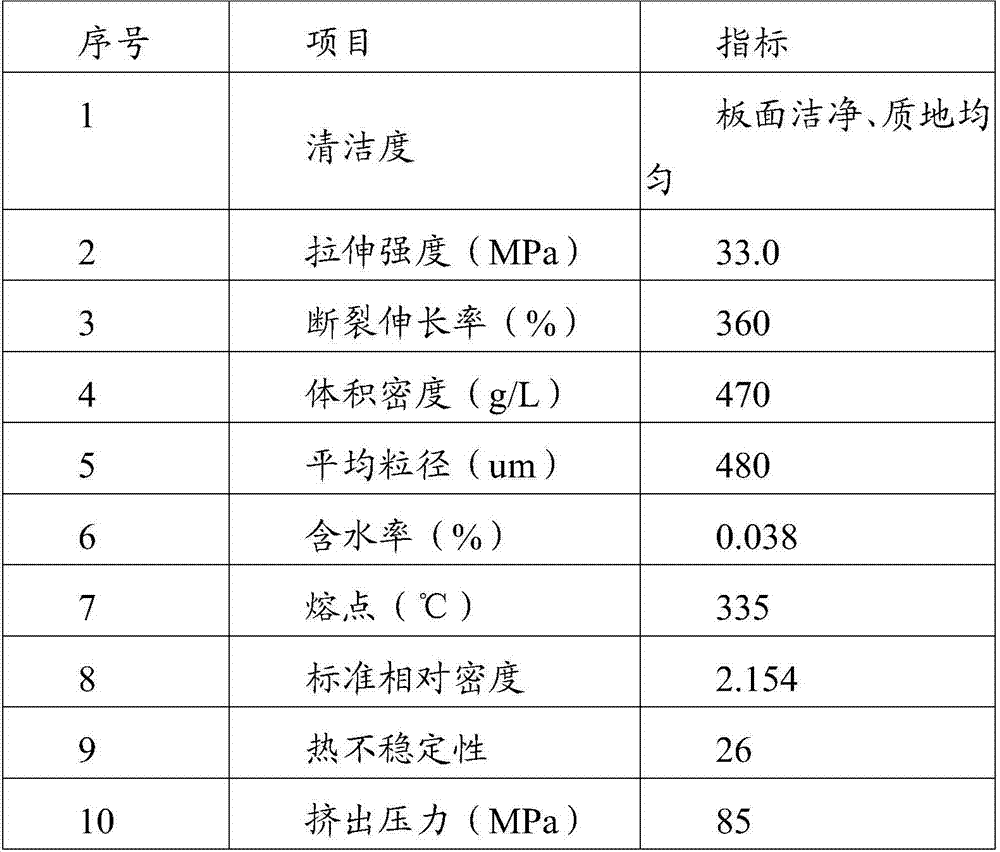

Examples

Embodiment 1

[0028] Step 1: Add 50% volume deionized water into the polymerization kettle, after vacuuming, add fluorine-containing surfactant, emulsion stabilizer, pH regulator and initiator, stir evenly, then pass in modified monomer, and Continue to add tetrafluoroethylene monomer until the pressure in the polymerization tank is 1.8MPa to start the reaction. During the reaction, the stirring speed is 60r / min, and the reaction time is 30min; add fluorine-containing surfactant accounting for 40% of the total addition amount;

[0029] Step 2: Continue to add the remaining tetrafluoroethylene monomer and fluorine-containing surfactant accounting for 40% of the total addition amount, and increase the rotation speed to 50-60r / min; the reaction time is 90min;

[0030] Step 3: After step 2, add the remaining fluorine-containing surfactant, accounting for 20% of the total addition amount, maintain the rotation speed at 30-40r / min, and the reaction time: 30minmin, to obtain the emulsion;

[0031]...

Embodiment 2

[0035] Step 1: Add 70% volume deionized water into the polymerization kettle, after vacuuming, add fluorine-containing surfactant, emulsion stabilizer, pH regulator and initiator, stir evenly, then pass in modified monomer, and Continue to add tetrafluoroethylene monomer until the pressure in the polymerization tank is 2.5MPa to start the reaction. During the reaction, the stirring speed is 70r / min, and the reaction time is 35min; add fluorine-containing surfactant accounting for 40% of the total addition amount;

[0036] Step 2: Continue to add the remaining tetrafluoroethylene monomer and fluorine-containing surfactant accounting for 40% of the total addition amount, and increase the rotation speed to 50-60r / min; the reaction time is 90min;

[0037] Step 3: After step 2, add fluorine-containing surfactant accounting for 20% of the total addition amount, maintain the rotation speed at 40r / min, and the reaction time: 30min to obtain the emulsion;

[0038]The total reaction tim...

Embodiment 3

[0041] A kind of preparation method of the tetrafluoroethylene dispersed resin of long fiber for making base cloth, comprises the steps:

[0042] Step 1: Add 2600L of deionized water to a 4000L polymerization kettle with a horizontal spiral stirrer, vacuumize, add 1.2kg of ammonium perfluorooctanoate, 75kg of paraffin, 1.3kg of succinic acid and 7g of ammonium persulfate, and close the inlet and outlet with nitrogen Replace and analyze that the oxygen content is less than 20ppm, raise the temperature of the reactor to 75°C, add hexafluoropropylene, and continue to add tetrafluoroethylene monomer until the pressure in the kettle is 2.2Mpa, stir at a speed of 65r / min, start the reaction, and react for 30min;

[0043] Step 2: Continue to add the remaining tetrafluoroethylene monomer and 1.2kg ammonium perfluorooctanoate, increase the rotation speed to 55r / min, and continue the reaction for 90min; the added amount of hexafluoropropylene is 90kg;

[0044] Step 3: After step 2, add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com